The importance of factory automation and industrial PCBA

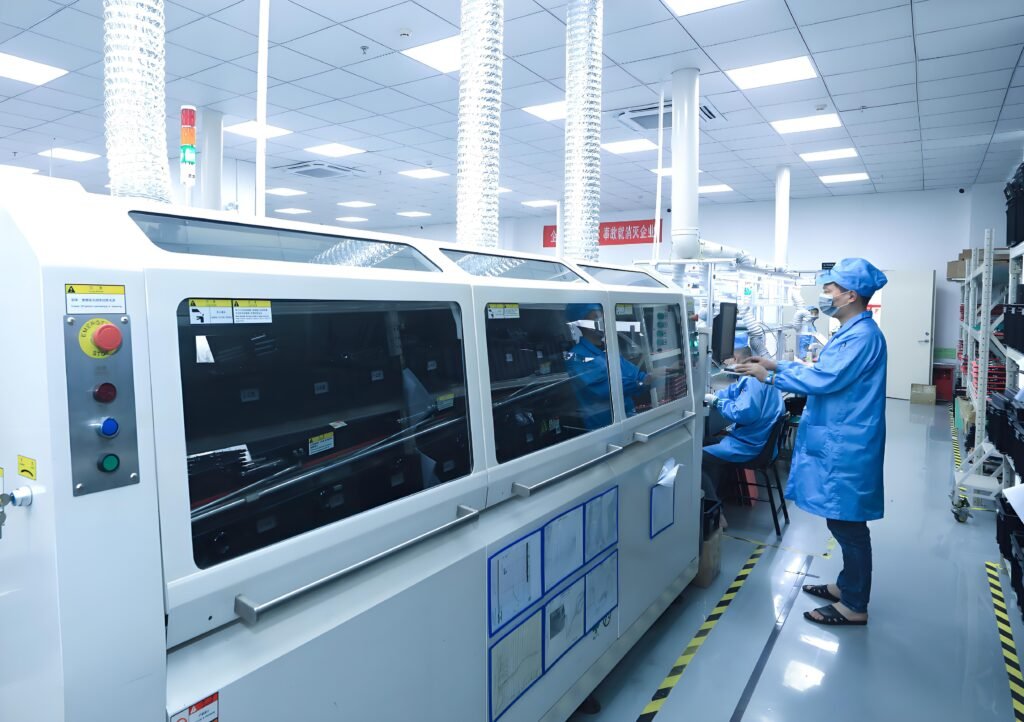

In the past, many tasks in factories relied on manual operations. This mode of production not only reduces industrial efficiency, but also exhausts workers physically and mentally. Fortunately, those days are history. Today, we invest a lot of money in industrial machinery and equipment, these high-end machines can complete a variety of complex processes in a short time with precision.

In order to ensure that engineers can produce factory equipment that meets various performance requirements, the standards for industrial PCB manufacturing are becoming increasingly stringent. Many people may think that the circuit board does not operate differently in different environments, but this view is clearly wrong.

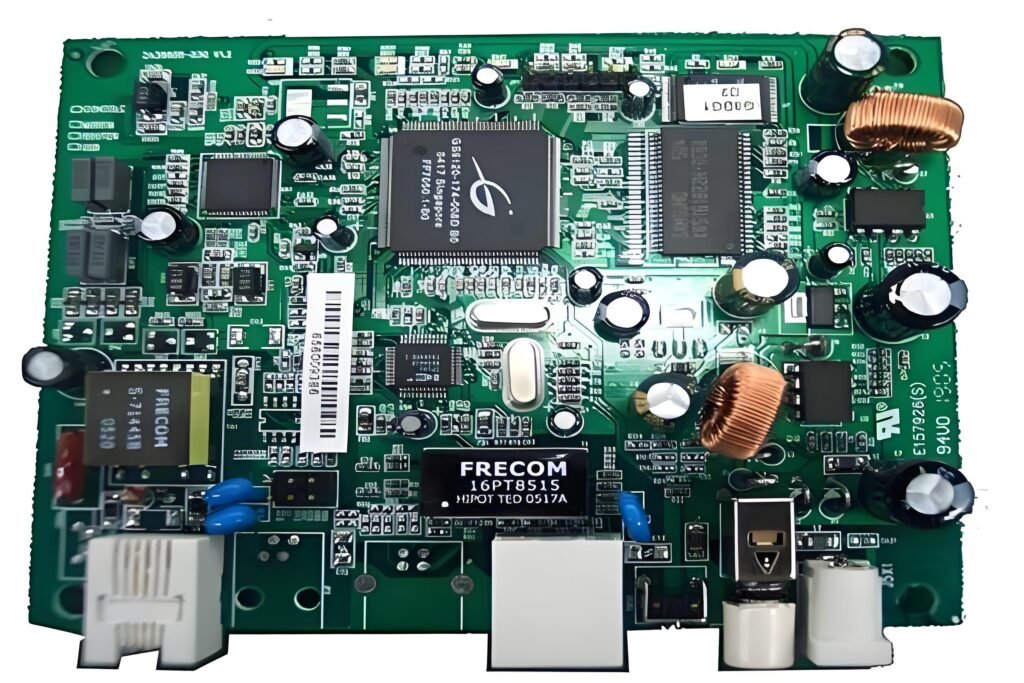

An industrial PCBA, also known as an industrial control board, is a circuit board designed to withstand shock, vibration, extreme temperature, humidity, and dust in industrial equipment. This PCBA is used in the industrial control industry to perform various operations. It is designed to configure the circuit of the project in a compact way so that the current can flow exactly along the desired path and enhance the operational performance of the product. These boards are a key component of industrial control projects and equipment, helping to measure and configure numerous parameters of the assembly line and obtain accurate physical quantities.

By using industrial PCBA, factories are able to achieve a higher level of automation, significantly improving production efficiency and product quality. These boards not only improve the durability and reliability of the equipment, but also reduce maintenance and downtime, resulting in higher economic benefits for the enterprise.

Top choice for high quality industrial control PCB/PCBA

If you are looking for high quality and affordable industrial control PCB/PCBA boards, we are the best choice for you. As a turnkey PCB assembly manufacturer that has served thousands of domestic and international enterprises over the past decades, we not only provide PCB and PCBA manufacturing services, but also meet customers’ special needs, rework and modifications to ensure customer satisfaction. With our professional working practices and dedicated attitude, we have won recognition from many leading manufacturers in the industrial sector.

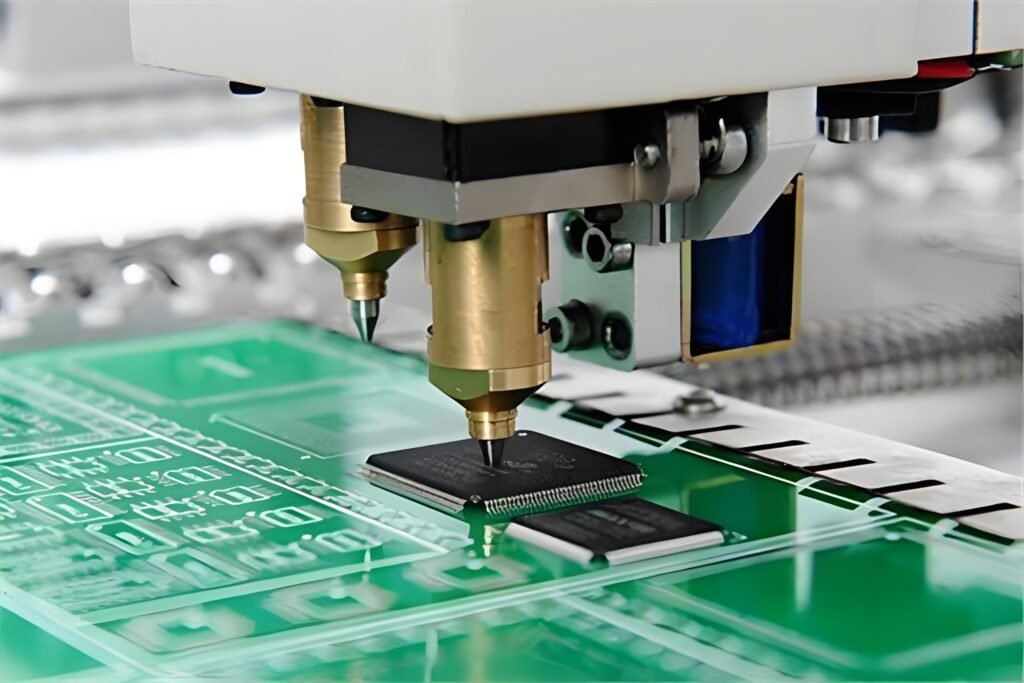

We specialize in the production of multi-layer industrial PCBS and provide one-stop PCBA services. Our process starts with a file or Gerber file sent by the user. After receiving these documents, our engineers review and establish manufacturing processes using various techniques to create PCB boards and PCBA projects for industrial control. Whether it is a simple or complex project, from small batch to high volume PCB assembly, from startups to industrial giants, we can meet the needs of our customers. Our team of experts executes projects through 1-on-1 project managers and is fully supported by purchasing, engineering, manufacturing and quality control teams.

With us, you will receive high quality products and excellent service to ensure that your industrial control projects run smoothly and achieve the desired results.

Taciti integer faucibus sollicitudin eros dolor fusce quam dapibus vulputate himenaeos ullamcorper consectetuer pede porttitor ultricies maximus nostra consectetur gravida risus lobortis

Stands for Safety Integrity Level, and measures the safety performance of Safety Instrumented Systems (SIS).

Is a process industry-specific standard that provides guidance for the specification, design, installation

Defines the design requirements for printed circuit boards, including board layout

Defines the design requirements for printed circuit boards, including board layout

Tests the flammability of plastic materials used in the construction of electronic equipment.

Is a directive that restricts the use of six hazardous substances in the manufacture of electronic and electrical equipment

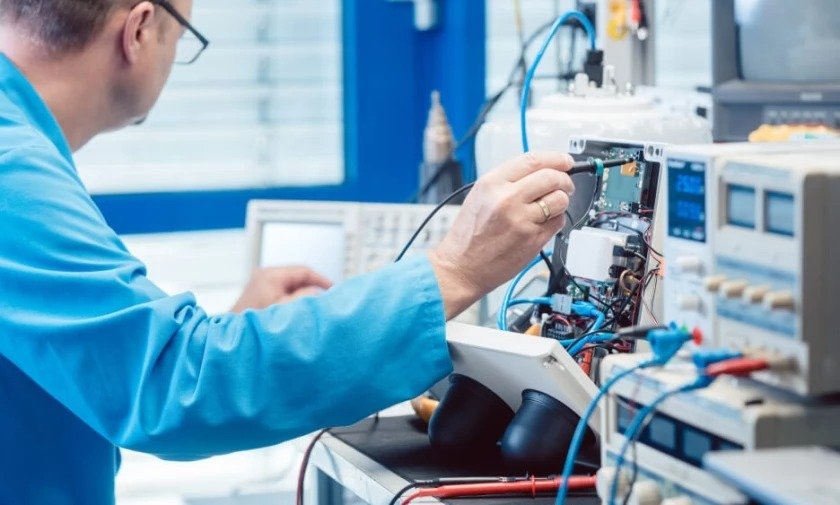

If you are considering outsourcing your PCBA project, it is vital to choose a manufacturer that can provide a high quality service at an affordable price. It is wise to look for suppliers with a good reputation and extensive experience in the PCBA industry. In addition to having a variety of relevant certifications and customer references, our company has a highly skilled team of engineers and employees who are proficient in microoperations and equipped with the most advanced instruments.

Consumer electronics PCBA is far less complex than industrial control machinery. Therefore, we recommend that our clients choose a turnkey solution for their complex projects. By choosing a turnkey supplier, you can rely on them to handle everything from the prototyping of industrial control panels to final production, testing and delivery. These manufacturers also have well-developed feedback systems that provide you with detailed information about your project from start to finish, ensuring that the project creation and management process is straightforward, and that you can respond to any queries in detail.

In the industrial control board industry, manufacturers that provide fast turnaround PCB assembly services are becoming increasingly important, especially in industries where technology is advancing rapidly or designs are changing frequently. Manufacturers with fast turnaround capabilities are able to respond more quickly to customer needs and gain insight into market trends.

In large industries, time is money. The longer a project takes to complete, the more expensive it will be to build. Therefore, it is wise to choose a supplier that can produce PCBS in a shorter period of time.

In the field of industrial control boards, inferior products are absolutely intolerable. When these boards are used in industrial equipment, any errors can result in significant losses for customers, including costs associated with downtime. Therefore, PCB manufacturers must implement strict quality management practices, which go beyond simple PCB inspection and involve many other factors to ensure the reliability and performance of the final product.

Choose us and you will receive high quality products and unparalleled service to provide a solid guarantee for your industrial control projects.

Industrial control board is a circuit board specially used for industrial control operations. Unlike commercial off-the-shelf boards, these boards are customized to specific needs and requirements. They are equipped with universal input and output (I/O) ports to connect a variety of peripherals such as valves, motors, and sensors.

In addition, there are some industrial control PCBS that are designed for specific operations, such as temperature control boards. The input end of these plates is connected to the thermocouple and the output end is connected to the heater controller, which is used to regulate the temperature of the device and the environment.

Industrial control panels are usually composed of two main materials: a non-conductive substrate and a copper wire and pad. The copper wires and pads act as interconnects on the PCB board, enabling individual components to communicate with each other. Depending on the complexity of the operation, these boards can be single, double or multi-layer. Single-layer plates have copper wiring on only one side, while double-layer plates have copper wiring on both sides.

These boards are also known as universal PCBS because they have programming capabilities that allow users to set up operations according to their needs. Programmable logic controller (PLC) is a typical example of general purpose industrial control board. By writing different programs and compiling inputs, the PLC can perform a variety of operations. It has a digital input, an analog input port, and a high-speed counter port for communication operations.

In industrial applications, it is critical to reduce the impact of electromagnetic interference (EMI) and radio frequency interference (RFI), which can generate noise and affect the proper operation of PCbas. To meet these challenges.

Board layout

Board layout:To reduce the risk of noise coupling, separate the high-frequency and low-frequency circuits and ensure that the signal routes are away from the power supply and ground plane. Shorten the length of the signal line as much as possible, increase the area of the power supply and ground plane, and use low inductance holes to connect the wiring to reduce the impedance of the power grid.

Filter element:Filter elements, such as capacitors and inductors, are added to power and signal lines to eliminate unnecessary noise. This helps keep the signal clear and stable.

Grounding and shielding technology:The sensitive element is enclosed in a Faraday cage to shield EMI and RFI interference. This method can effectively protect the normal operation of the circuit board.

Component selection:It is very important to select circuit board components with excellent grounding and shielding properties. The boards are connected using shielded wires to further reduce the possibility of interference.

In modern industry, printed circuit board components (PCBA) are the core components of various electronic devices. Whether it’s automation systems, industrial controllers, or a variety of sensors and communication devices, PCBA plays a vital role. However, due to its complexity and high precision requirements, PCBA may encounter various technical problems during production and application. Here are some common industrial PCBA problems and their solutions.

Welding defects: Use high-quality welding materials, optimize welding process parameters, and regularly maintain and calibrate welding equipment.

Electrical Performance instability:A comprehensive electrical simulation is carried out during the design phase to ensure proper circuit design. Use high-quality components to strictly control static electricity and pollution in the production environment.

Component failure: Select reliable suppliers and purchase high-quality components. Optimize circuit design to ensure components operate within their rated parameters.

Signal interference: In the design stage, reasonable layout of the lines to avoid crosstalk between signal lines. Use shielding materials and filters to reduce external electromagnetic interference.

Poor environmental adaptability: Select components and materials suitable for industrial environments. Perform environmental adaptability tests such as high and low temperature tests, heat and humidity tests and vibration tests.

Long-term cooperation ensures the stability of the supply chain, reduces the risk of supply disruptions, and guarantees the continuity and reliability of production.

Through long-term cooperation, suppliers and customers are able to establish consistent quality standards, ensure product consistency and high quality, and reduce rework and quality issues.

Economies of scale and long-term orders help reduce production and procurement costs, provide more competitive prices and improve profit margins.

Long-term partners can jointly invest in research and development projects, share technology and knowledge, drive innovation and maintain technological leadership.

In-depth understanding of customer needs, to provide tailored solutions to meet specific requirements, enhance product competitiveness and customer satisfaction.

Close cooperation enables both parties to respond more quickly to market changes and demand adjustments, maintaining market competitiveness and flexibility.

Long-term partners can jointly cope with market fluctuations and other uncertainties, share risks and enhance resilience to risks.

Through regular feedback and evaluation, both parties can continuously optimize production processes and quality management systems

In the industrial PCBA industry, it is essential to establish a diversified global supplier network. Establish partnerships with multiple suppliers to ensure a stable supply of key components and reduce the risk of a single supplier. At the same time, strategic partnerships are established with leading component manufacturers to ensure long-term supply quality and price stability.

The advanced supply chain management system enables visual monitoring of the whole process from raw material procurement to finished product delivery. Improve supply chain responsiveness and decision accuracy by optimizing inventory management and production planning through data-driven decision making. This transparency and optimization can effectively reduce inventory costs and production cycles.

Set up storage centers in key markets around the world to reduce delivery times, improve logistics efficiency and reduce transportation costs. Intelligent logistics system is adopted to optimize transportation routes and track the status of goods in real time to ensure on-time delivery. Through these measures, companies can significantly improve the reliability of logistics services and customer satisfaction.

Establish a flexible supply chain structure to prevent the impact of natural disasters, political risks and other emergencies on the supply chain. Develop detailed contingency plans to ensure rapid recovery of production and delivery in the event of supply chain disruptions. Choose environmentally friendly materials and implement circular economy strategies to drive sustainable development and reduce carbon footprint and environmental impact.

High Performance substrates: High performance substrates such as ceramic substrates and high thermal conductivity materials can significantly improve the heat dissipation and electrical performance of PCBA. These materials perform particularly well in high-frequency, high-power applications, meeting the high performance and miniaturization needs of modern electronics.

Flexible and Rigid flexible materials: Flexible and rigid flexible materials (rigid-Flex) offer the possibility of designing complex three-dimensional circuits. These materials not only reduce weight and save space, but also improve the reliability and durability of products, especially for wearables and mobile communication devices.

Environmentally friendly materials: With the increasingly strict environmental regulations, the use of lead-free solder and environmentally friendly solder resistance has become a trend. These environmentally friendly materials not only meet international environmental standards, but also reduce their environmental impact and promote sustainable development.

Nanomaterials and composites: Nanomaterials and composites show great potential for improving PCBA performance. Nanoscale conductive materials can improve electrical conductivity and durability of circuits, while composite materials can provide better mechanical strength and electrical insulation.

In the industrial PCBA industry, fast and accurate quotation is a key factor for customers to make purchasing decisions. Our company is committed to providing an efficient quotation system that helps customers get accurate project quotations quickly, avoid budget overruns, and accelerate project implementation by simplifying processes, improving response speed, and ensuring quotation transparency.

Our quotation system is designed to be simple and clear, so customers can quickly get a quote by following the following steps:

Submit design documents: Customers upload detailed design documents, including Gerber files, BOM (Bill of Materials), assembly drawings, and test requirements.

Fill in the basic information: The customer fill in the basic information of the project, such as production quantity, delivery time and special requirements.

Automated processing: The system automatically analyzes design documents and bills of materials, and calculates material costs and production expenses in real time.

Immediate feedback: Within minutes, customers receive a detailed quotation, including a transparent breakdown of each cost.

When manufacturing industrial control PCBS, the choice of materials is crucial and must be selected according to the specific working environment. PCB materials in industrial applications need to be able to withstand a variety of harsh conditions, such as high temperature, high pressure, moisture, vibration and chemical erosion. Here are some of the materials commonly used in industrial PCBS:

Polyimide: Polyimide is a high-performance material that can withstand extreme temperatures of up to 400°C and is commonly used in aerospace, military and high-temperature industrial control applications.

Ceramic: Ceramic PCB is composed of ceramic substrate and metal wire, has excellent thermal conductivity, can handle high temperature and harsh chemical environment. They are commonly used in power electronics and high frequency fields.

PTFE: PTFE (polytetrafluoroethylene) is a fluorinated polymer that has excellent electrical insulation properties and can withstand high temperatures up to 260°C. It is commonly used in high frequency and microwave applications, as well as harsh chemical environments.

FR-4: FR-4 is a composite material made of woven glass fiber cloth and epoxy resin and is one of the most common PCB materials, including in industrial applications. FR-4 PCB has good electrical insulation performance, can withstand high temperature and chemical erosion.

By selecting the right material, industrial control PCBS can operate stably in a variety of complex and harsh environments, ensuring the reliability and performance of the equipment.

4th floor,C building , High-tech International Innovation Center, Kelian Road, Yutang Street, Guangming New District, Shenzhen

long@custompcba.com

+86 18123721954