In the face of tight margins in the consumer electronics sector, ensuring high-quality production of PCBS and their components has become particularly critical. To achieve cost effectiveness and long-term success, working with a professional PCBA master contractor in China is an indispensable part.

We serve a wide range of consumer electronics fields such as home appliances, entertainment electronics, intelligent digital equipment, relying on comprehensive manufacturing and assembly expertise, strict control of every production link to ensure excellent service quality and meet various testing standards.

Whether it’s PCBA prototype development for consumer electronics or mass production needs, we offer a one-stop “turnkey” solution to help you easily meet market challenges and achieve a double leap in cost and quality.

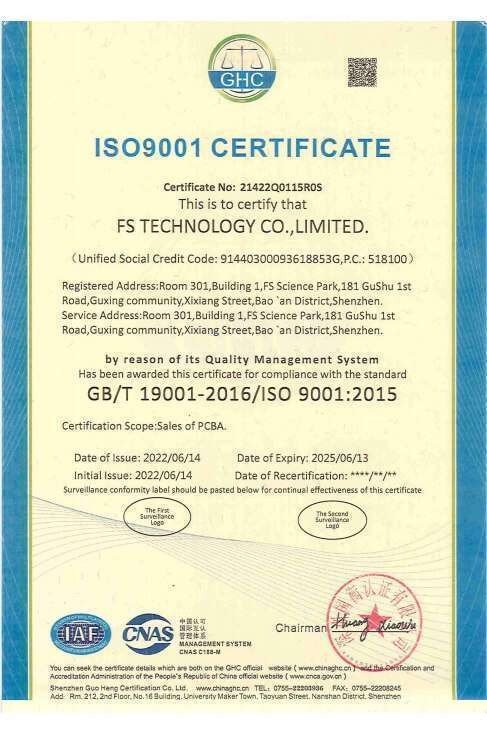

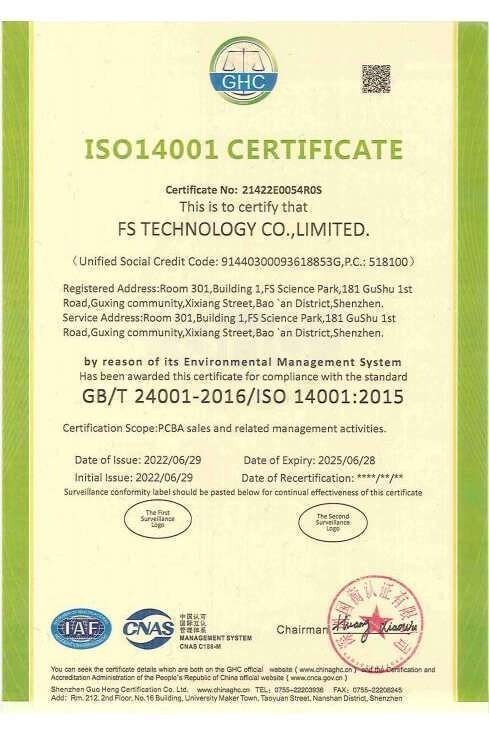

As a well-known PCBA one-stop service provider, we understand the way of technological innovation and service excellence. We focus on providing comprehensive services covering SMT assembly, THT assembly and various PCB manufacturing, and constantly improve to meet customer needs. Our international certifications, including ISO 9001, ISO 14001, ISO 45001, ISO 13485 and IATF 16949, are a testament to our ability to deliver high quality services across a wide range of industries beyond consumer electronics.

We adhere to a strict quality management system to ensure that every business reaches a standard of excellence, achieving service consistency and scalability. Our headquarters in Shenzhen, China, is the starting point of our global service network. With an experienced team of professionals, we have demonstrated extraordinary strength in manufacturing, assembly, testing and customer support to bring a worry-free service experience to customers around the world.

We specialize in customized PCB solutions for the consumer electronics industry, whether it is the pursuit of the ultimate thin and light small circuit, or the need to withstand the extreme environment of the rugged through hole board, we can precisely meet.

From everyday consumer electronics to complex industrial control systems and even cutting-edge autonomous driving technology, our products are integrated into a wide range of application scenarios to ensure stable operation and uninterrupted function of electronic devices.

Whether your project is nascent or mature, FS Technology is your trusted partner. First of all, our sales team will be your primary contact window; In the face of technical challenges, our engineering team is able to provide cost-effective and efficient solutions within tight timeframes. We promise that in every step of cooperation, we will walk side by side with you to create brilliance.

We are deeply engaged in the field of customized services, committed to meeting the unique needs of customers, from service project design to implementation, the whole process of flexible customization. Not only do we serve a wide range of industries, we are also good at creating exclusive prototypes for our customers to facilitate the rapid validation and optimization of product concepts. When it comes to consumer PCBA services, we provide professional services including but not limited to the following, to ensure that every detail is precisely matched to your expectations.

FS Technology has a wide range of PCB manufacturing capabilities, and for most consumer electronics, 1-6 layer circuit boards are sufficient to meet the demand. Apart from the number of layers, we can also cater to various requirements, such as rigid, flexible, and rigid flex PCB.

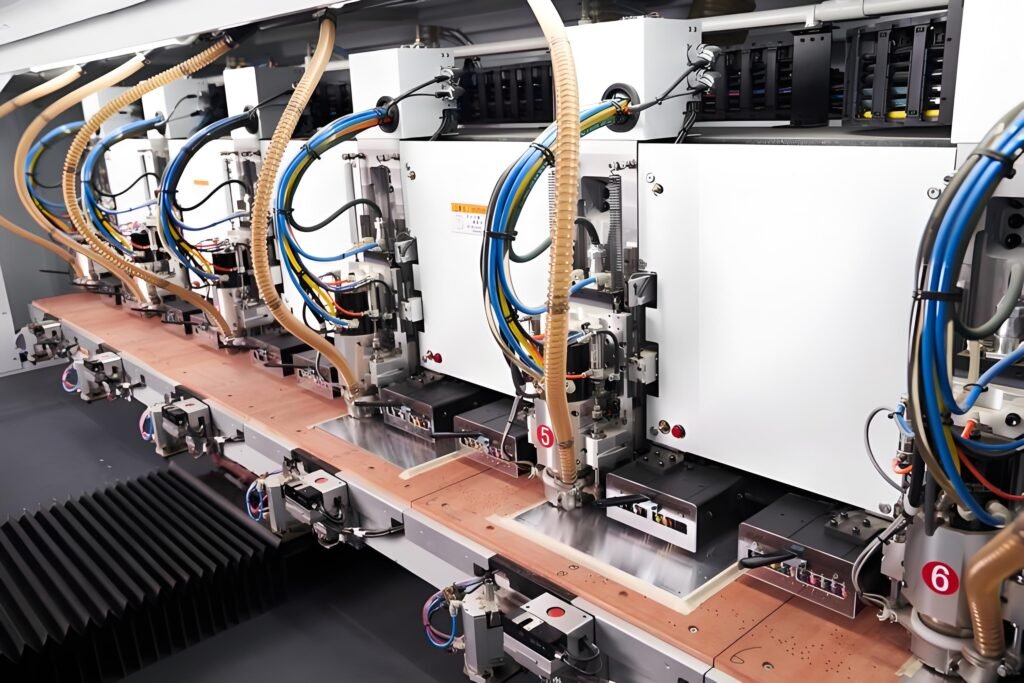

Although through hole PCB assembly is an older form of assembly, many demanding consumer electronics manufacturers still use it. Compared to advanced SMT technology, it is more labor-intensive since it usually involves manual work, which does not align with the needs of consumer electronics as most consumer products are mass-produced. FS Technology has a solution for this. We have introduced advanced automatic through-hole equipment that can easily complete large-volume orders.

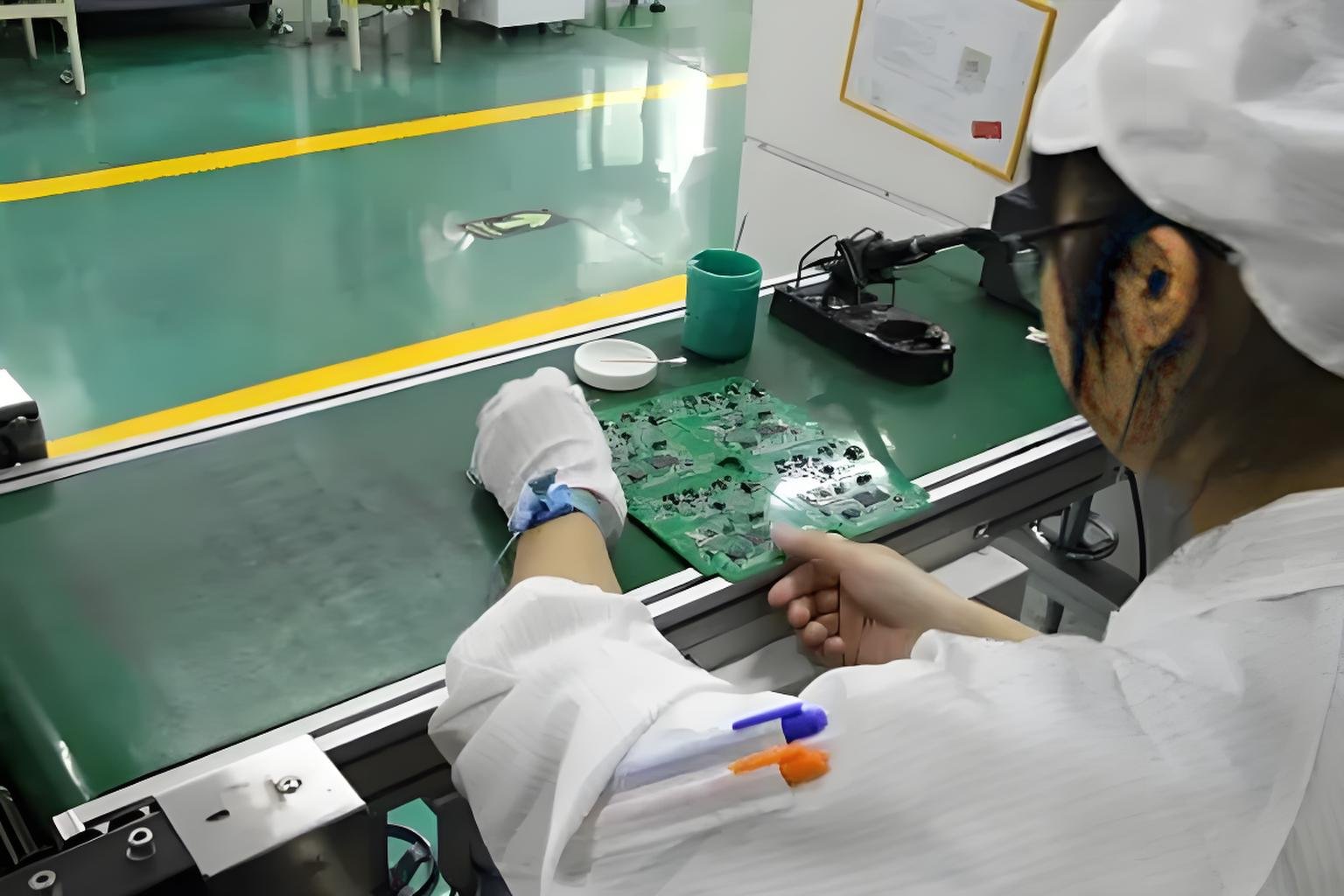

SMT, or surface mount technology, is a more advanced form of PCB assembly that uses automatic pick-and-place robots to accurately place the required components on the board and then firmly solder them in place. At FS Technology, we adhere to IPC-A-610-G standards and use both leaded and ROHS technology for SMT assembly. Our facility is equipped with a variety of screen printing and component placement machines, as well as X-ray testing and other equipment to ensure a high level of quality control.

Artificial intelligence is a widely discussed topic and has been integrated into various industries, particularly in consumer electronics. These applications require enhanced computing power to simulate human speech and improve user experience. Printed circuits play a critical role in meeting these high-performance requirements

The trend towards miniaturization in consumer electronics, particularly in wearable devices and smart homes, is becoming more evident. Manufacturers of electronic products are increasingly demanding smaller PCBAs, from smartwatches that monitor physical conditions to smart devices that control LED lights and switches.

Consumer expectations for electronic products are continuously increasing, with users demanding more functionality from the same device. As a result, the requirements for PCBs in consumer electronics have also significantly increased. To meet this demand, manufacturers are utilizing advanced materials such as resin-coated copper

The consumer electronics industry is encountering environmental challenges due to the need to use electronic devices in various extreme environments. In response to this trend, FS Technology is integrating built-in electrostatic discharge (ESD) protection in micro-devices and substrates during PCB manufacturing process.

Size and shape optimization: For portable electronic products such as smart phones and smart watches, PCB design needs to closely fit the miniaturization trend of equipment, lightness and compactness have become the main axis of design. At the same time, it needs to be cleverly arranged to ensure harmonious coexistence and seamless integration with other precision components inside.

Strengthening durability: In view of the fact that consumer electronics products often face harsh environments such as high temperature, humidity and mechanical impact, the choice of PCB materials is crucial. The use of high-quality materials to enhance the weather resistance and wear resistance of the circuit board to ensure stable operation in variable environments.

Pursuing the ultimate in energy efficiency: Energy management is a challenge in limited equipment space. The design should focus on the miniaturization and high efficiency of key components such as capacitors, and strive to achieve high power output while effectively reducing energy consumption and extending the battery life of the equipment.

The art of PCB design: laying the foundation for high-quality production. A well-designed PCB can not only improve product performance, reliability and durability, but also effectively reduce the manufacturing cost of consumer electronics. The design process covers many links, starting from the schematic drawing, through the layout planning, and finally to the Gerber file output, each link is crucial.

Schematic idea: Blueprint drawing of circuit function. At this stage, carefully select components, carefully plan the power network, integrate filtering and protection mechanisms, and pass strict testing and verification to ensure that the circuit logic is correct and the layout is scientific and reasonable.

PCB layout planning: the cornerstone of stable performance of electronic equipment. It is necessary to comprehensively consider the size and shape limitations of the equipment, rationally plan the number of layers, accurately locate the components, ensure the integrity of signal transmission, optimize the layout of the power supply and grounding, design the cooling scheme cleverly, and strictly follow the EMC specifications to create an efficient and stable circuit platform.

Bare board birth: As the beginning of the PCBA production chain, bare board manufacturing carries the heavy task of building the circuit foundation. Glass fiber or high-performance plastic resin is selected as the base, covered with copper foil, and then precision chemical etching technology is used to accurately remove excess copper layers and carve out precision conductive venation connecting electronic components, laying the cornerstone of the circuit board function.

Precise positioning of components: Following the bare plate, the careful assembly of electronic components. The automated robot arm shows its skill, accurately grabs the components, and is firmly placed in the preset position of the circuit board. Subsequently, wave soldering or reflow welding technology takes turns to weld the components and the circuit board firmly as one, ensuring the stability and reliability of the circuit connection.

Strict quality control: Quality control, as an invisible link throughout the PCBA manufacturing process, its importance is self-evident. We insist on embedding quality inspection in each process, once any defect is found, immediately launch an emergency response mechanism, suspend production, in-depth analysis of the root cause of the problem, and quickly develop solutions, and strive to nip the defect in the bud, and protect the excellent quality of the final product.

We use advanced surface mount technology (SMT) to handle ultra-small components, ensuring accurate assembly of high-density circuit boards with high-precision mounters and AOI inspection equipment.

Multilayer printed circuit boards (PCBS) capable of producing up to 20 layers are suitable for high-performance equipment, ensuring circuit complexity and functionality, providing high-precision alignment and reliable electrical connections.

Adopt lead-free welding process, in line with RoHS standards, use reflow welding, wave soldering and selective welding, strict control of welding temperature, to ensure solder joint reliability.

Establish a complete test system, including functional testing, online testing, aging testing and environmental testing, to ensure the stability and reliability of products in various environments.

Provide rapid prototyping and small batch production services to help customers quickly validate designs and functions, flexibly respond to changes in market demand, and quickly respond to the market

Provide a full range of customized services, from circuit design to complete machine assembly, to meet customer specific needs, to ensure the feasibility and optimization of design solutions.

Consumer electronics PCBA is far less complex than industrial control machinery. Therefore, we recommend that our clients choose a turnkey solution for their complex projects. By choosing a turnkey supplier, you can rely on them to handle everything from the prototyping of industrial control panels to final production, testing and delivery. These manufacturers also have well-developed feedback systems that provide you with detailed information about your project from start to finish, ensuring that the project creation and management process is straightforward, and that you can respond to any queries in detail.

Consumer electronics PCBA is far less complex than industrial control machinery. Therefore, we recommend that our clients choose a turnkey solution for their complex projects. By choosing a turnkey supplier, you can rely on them to handle everything from the prototyping of industrial control panels to final production, testing and delivery. These manufacturers also have well-developed feedback systems that provide you with detailed information about your project from start to finish, ensuring that the project creation and management process is straightforward, and that you can respond to any queries in detail.

Consumer electronics PCBA is far less complex than industrial control machinery. Therefore, we recommend that our clients choose a turnkey solution for their complex projects. By choosing a turnkey supplier, you can rely on them to handle everything from the prototyping of industrial control panels to final production, testing and delivery. These manufacturers also have well-developed feedback systems that provide you with detailed information about your project from start to finish, ensuring that the project creation and management process is straightforward, and that you can respond to any queries in detail.

Through the introduction of automatic placement machines, reflow welding equipment and automatic optical inspection (AOI), production speed and accuracy are greatly improved, manual errors are reduced, and efficient production is achieved.

Lean production methods are adopted to optimize each production link, reduce waste and unnecessary operations, and improve production efficiency and product quality.

Using modular design and flexible production line configuration, combined with information management systems (such as ERP and MES), quickly adjust production plans to meet diverse order needs and achieve efficient manufacturing.

Through big data analysis and machine learning technology, we can monitor and optimize production processes in real time, predict and reduce failures, and improve overall production efficiency and product quality.

In the start-up phase of every project, quality assurance is always our top priority. In order to achieve this goal, we strictly follow internationally recognized authoritative standards and third-party certifications, including ISO, UL, RoHS and IPC.

In order to meet the diverse needs of our customers, we have obtained ISO9001, ISO14001, ISO/TS16949 and ISO13485 certifications. These certifications demonstrate our ability to produce boards for a variety of industries, including consumer electronics, medical electronics and automotive electronics.

By adhering to the highest quality standards and a commitment to certification, our customers can rest assured that they are working with a reliable and trusted PCB manufacturer.

Product design

We have an experienced design team that can provide professional advice and support during the concept stage of the product. Whether it is functional design or visual design, we are able to provide innovative solutions according to the needs of our customers. Through the use of advanced design tools and techniques, we ensure that every design detail meets the expectations of our customers and meets the needs of the market.

Prototype development

After the product design was completed, we quickly moved into the prototype development phase. Using rapid prototyping technology and 3D printing technology, we are able to produce high-precision prototypes in a short time. Through prototype testing, we can find and solve problems in the design in time, ensuring that the product is in the best condition before it goes into production.

Material selection

The choice of material is crucial to the performance and quality of the product. Working with the world’s leading material suppliers, we are able to offer our customers a wide selection of quality materials. Our team of engineers will recommend the most suitable materials according to the functional requirements and use environment of the product to ensure the reliability and durability of the product.

Manufacturing process optimization

In the manufacturing stage, we ensure that every product can meet high standards through advanced manufacturing processes and strict quality control. Our use of automated production lines and intelligent manufacturing systems can significantly improve production efficiency and reduce production costs. Our process engineers continuously optimize the manufacturing process to ensure the stability and consistency of product quality.

Specific case presentation

We helped a startup take its innovative smart home device from a concept design to a hit in the market. In the design phase, we provided a variety of solutions for customers to choose from, and completed the prototype development in a short time. Through rigorous material screening and manufacturing process optimization, we ensure the high quality and reliability of our products. Finally, the product was successfully launched and quickly occupied the market, and customers highly appreciated our comprehensive support.

Rich industry experience

We have extensive experience in multiple industries, especially in meeting complex customer needs and technical challenges. Whether it is consumer electronics, medical equipment or industrial control systems, we can provide professional solutions. Our team is familiar with the standards and specifications of various industries, and can provide customized services to customers to ensure that products meet industry requirements.

Taciti integer faucibus sollicitudin eros dolor fusce quam dapibus vulputate himenaeos ullamcorper consectetuer pede porttitor ultricies maximus nostra consectetur gravida risus lobortis

Strictly follow international environmental standards to meet the needs of major customers.

Use lead-free welding and low energy consumption equipment to reduce pollution.

RoHS and REACH standard materials are used to ensure that they are harmless.

Certifications such as ISO 14001 enhance customer trust.

Achieve customer environmental goals and win trust

Optimize processes and help well-known electronics companies meet

Consumer electronics have become an indispensable element of modern life, and they are specifically designed for personal daily needs, entertainment experiences and communication. This category covers a wide range of smart phones, tablets, laptops, high-definition TV, game consoles, digital cameras, smart wear and all kinds of convenient life gadgets, which with powerful functions and convenient operation, profoundly affect our way of life.

These products are characterized by mass production and aim to achieve the perfect combination of affordable, easy to operate and stylish appearance. With the rapid development of technology, the field of consumer electronics continues to innovate, and constantly meet the growing diversified needs and personalized preferences of consumers. Smart phones, laptops, gaming terminals and smart watches are making our daily lives more convenient and connected in an unprecedented way, and enjoying the fun of information access, entertainment and social interaction anytime and anywhere.

A printed circuit board (PCB), the core building block of an electronic device, is a flat plate made of a non-conductive substrate, such as a fiberglass cloth or plastic resin, with intricate copper wiring finely etched onto the surface. These copper rails not only act as conductive Bridges, connecting key components such as resistors, capacitors, and integrated circuits (ics), but also form the vein of complex circuits inside electronic devices. According to the design complexity, PCB can be divided into single layer and multi-layer structure, the former is only on the side of the board layout copper layer, while the latter is cleverly laid in the multi-layer board in order to achieve higher density circuit integration.

Looking around, it is not difficult to find that from the smart phone in the palm to all kinds of appliances at home, there is no PCB wisdom crystallization. PCB, like the invisible skeleton of electronic products, although it is not obvious, it silently supports and drives every operation of these devices. Consumer electronics PCBS are tailored to consumer needs, and they pursue a smaller volume, higher integration and better energy efficiency ratio to meet the market’s comprehensive requirements for portability, functionality and economy. At the same time, the mass production capacity of consumer electronics PCB also makes it a powerful driving force to promote the vigorous development of the consumer electronics industry.

To ensure that customers can easily start working with us, we have designed a simplified three-step process: submit a requirement, obtain a solution, and confirm an order. Help customers start projects quickly through efficient communication and streamlined processes.

Step 1: Submit the requirements

Online submission of information: Customers visit the company website, fill in the basic information and upload the design document (e.g. Gerber file, BOM, etc.).

Initial consultation: The account manager contacts the customer within 24 hours to confirm the information and understand the specific needs.

Step 2: Get the solution

Professional evaluation: The engineering team evaluates design documents and requirements to confirm technical feasibility.

Provide quotation and plan: The system generates detailed quotation and project implementation plan, and the customer discusses and optimizes the plan with the team.

Step 3: Confirm the order

Confirm quotation and scheme: The customer confirms the final quotation and scheme and signs the contract.

Project start-up: The production team starts the project, regularly reports the progress and delivers the products on time, provides technical support and after-sales service.

4th floor,C building , High-tech International Innovation Center, Kelian Road, Yutang Street, Guangming New District, Shenzhen

long@custompcba.com

+86 18123721954