In today’s digital world, devices constantly communicate by transmitting signals between circuit boards. For any operation to be executed, seamless data transfer is essential between components. This is made possible by a small but crucial element: the golden finger.

Golden fingers are connectors found on circuit boards like motherboards, graphics cards, and sound cards. These connectors serve as the contact points that enable communication between different components. The concept revolutionized early electronics, which were often made up of independent modules that struggled to interact with one another. With golden fingers, a central processor can instantly access data from various boards, streamlining the process of signal transmission.

This technology plays a vital role in many industries today. In manufacturing, machines equipped with circuit boards send signals to automate tasks—many of which would be impossible to perform manually. Whether it’s in car assembly lines or food packaging facilities, golden fingers ensure that equipment operates smoothly, connecting the systems that power industrial processes.

But what exactly are golden fingers, and why are they so critical to the inner workings of modern technology? Let’s dive deeper into their significance and applications.

What is a Gold Finger?

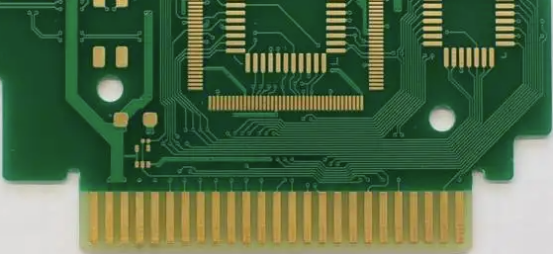

A gold finger refers to the gold-plated connectors located on the edges of a printed circuit board (PCB). These connectors play a crucial role in linking secondary PCBs to a computer’s mainboard, ensuring seamless signal transmission between different circuit boards. Gold fingers are commonly used not only in computer motherboards but also in a wide range of consumer electronics, including smartphones, smartwatches, and other devices that require efficient signal and power transmission.

Due to gold’s excellent conductivity, it is the ideal material for the connectors in PCBs, ensuring high-quality and reliable signal transfer. The design and functionality of gold fingers are vital components that make electronic devices perform efficiently and reliably.

PCB Gold Finger Plating Processes

There are two main gold plating processes commonly used for gold fingers on PCBs:

- Electroless Nickel Immersion Gold (ENIG):

The ENIG process involves plating a thin layer of gold over a nickel surface. This method is cost-effective and provides good soldering properties, making it suitable for assembly processes. Typically, the gold layer thickness is between 2-5 microns. However, ENIG gold is relatively soft, and due to its thin coating, it is not suitable for applications requiring frequent insertion and removal. The soft gold plating can wear out over time due to mechanical stress. - Hard Gold Electroplating:

Hard gold plating involves electroplating a thicker gold layer (typically 30 microns) over the PCB connectors. This gold layer is much harder and more durable, making it better suited for applications where the PCB will experience regular use and wear. Hard gold plating offers excellent durability and is commonly used in devices that require frequent mating and unmating of connectors.

How Gold Fingers Work

The primary function of gold fingers is to facilitate the transmission of electrical signals between different PCBs and components. When a signal is initiated by a device, it passes through the gold finger connectors and transfers to the corresponding circuit board or device. For example, when you press a button on your mobile device, the signal travels through the PCB in the device and is transmitted via the gold fingers to the receiving equipment, which then processes the command.

Gold Finger Plating Process

The gold finger plating process involves several meticulous steps to ensure that each PCB is fully equipped to conduct signals without errors. First, a nickel layer is applied to the copper PCB substrate to enhance the adhesion of the gold. Afterward, the gold plating is applied to the PCB connectors. Once the plating is complete, the circuit board undergoes extensive inspections to verify that the gold fingers will seamlessly match the corresponding slot on the motherboard.

These inspections include tests for surface smoothness and the adhesion strength of the gold layer. If the gold plating is not smooth or adheres improperly, it could lead to failures in the signal transmission, rendering the PCB unsuitable for commercial use.

Quality Control and Testing

To ensure the quality of the gold fingers, PCB manufacturers implement rigorous quality checks and defect testing throughout the production process. Each gold finger must perfectly match the corresponding slot on the motherboard to ensure reliable signal transmission. If the gold plating is uneven or does not adhere properly, it can cause signal issues, affecting the overall functionality of the device.

After plating, PCBs go through further steps to ensure the connectors are properly fitted and the gold layers are intact. These steps may include visual inspections, magnification checks, and adhesion testing to guarantee the components will perform as expected in real-world applications.

Gold fingers are an indispensable component in modern electronic devices, offering reliable and efficient signal transmission between PCBs. Their excellent conductivity and durability make them essential in ensuring the smooth operation of electronic products, from computer motherboards to smartphones. As technology evolves, the gold finger plating process continues to improve, providing higher standards of quality and performance for increasingly demanding applications.

How Gold Fingers Are Used in PCB Applications

Gold fingers are crucial for connecting adjacent printed circuit boards (PCBs), enabling efficient signal transmission and ensuring long-term durability through repeated connections. Gold is widely used in these connectors because of its excellent electrical conductivity and corrosion resistance, but its additional benefit lies in its ability to protect the connecting edges of the PCB from wear over time. The robust hardness of hard gold plating allows gold fingers to endure up to 1,000 insertion and removal cycles without significant degradation, making them essential for many industrial and consumer electronics.

Common Uses of Gold Fingers in PCBs

Gold fingers are employed in a variety of applications across different computing and industrial systems. They act as conductive interfaces that allow PCBs to connect and communicate with each other. Here are some of the most common uses for gold fingers:

- Connection Points Between PCBs

Gold fingers provide a reliable interface for connecting secondary PCBs to a mainboard. These connections are typically made through various types of motherboard slots such as PCI (Peripheral Component Interconnect), ISA (Industry Standard Architecture), and AGP (Accelerated Graphics Port). By inserting a secondary PCB into one of these slots, the gold fingers facilitate the transfer of digital signals between the peripheral devices and the mainboard. The gold fingers ensure these signals are transmitted reliably over long periods, maintaining the system’s stability. - Specialized Adapter Cards

Gold fingers are often used in adapter cards that enhance the capabilities of personal computers. These cards are typically inserted vertically into the motherboard to provide specialized functions, such as advanced graphics processing or high-fidelity sound. Since these cards are generally not removed or reinserted frequently, gold fingers often outlast the cards themselves. The durability of gold fingers ensures the card can be used for extended periods while providing high-performance functionality. - External Peripheral Connections

Many external devices—such as speakers, subwoofers, printers, scanners, and monitors—are connected to a computer through specific slots on the motherboard, which, in turn, are linked by gold fingers. These external connections are often found at the rear of a computer or device, with gold fingers enabling the interface between the peripheral device and the motherboard. The gold-plated connectors ensure that the communication between these devices and the main system remains efficient and stable, regardless of the frequency of use. - Power Supply for Modules

In a computer or embedded system, gold fingers play an essential role in powering the modules or cards that make up the system. They provide a reliable pathway for the transmission of power to different components, allowing devices to function as expected. Whether for individual cards in a computer or for machinery in industrial applications, gold fingers ensure that power is delivered accurately and consistently.

Flexibility of PCB Systems for Long-Term Upgrades

One of the advantages of using gold fingers in PCB systems is their ability to provide flexibility for future upgrades. Different slots on the motherboard are designed to accept various types of adapter cards, allowing for the ongoing enhancement of a system’s capabilities. For example, when upgrading the sound or graphics card, the existing card can be removed and replaced with a newer, more advanced model. The gold fingers ensure that each new card will fit seamlessly into the same slot, maintaining compatibility across different hardware generations. This flexibility allows a system to be continuously upgraded for many years, making gold fingers a long-lasting and adaptable solution.

Use of Gold Fingers in Industrial Applications

Beyond personal computers, gold fingers are also found in automated industrial machinery. In factories such as those in the automotive or stamping industries, various machines rely on internal cards connected by gold fingers to perform complex tasks. For example, robotic arms in a manufacturing plant may be powered by cards with gold fingers that enable precise control of movement and actions. Gold fingers in these applications play a critical role in ensuring that the machines can be operated efficiently and reliably over time, with minimal wear and tear.

Gold fingers are integral components that enable reliable, long-lasting connections between PCBs in a wide range of applications. From computers to industrial machinery, their durability and excellent conductivity ensure that devices can communicate effectively over long periods, providing stable performance and easy upgrades. As technology continues to advance, gold fingers will remain a key element in the evolution of electronic and industrial systems, offering a seamless connection solution for modern devices and applications.

Understanding the Key Specifications of Gold Fingers in PCBs

In the PCB (Printed Circuit Board) gold finger plating process, strict guidelines must be adhered to in order to ensure that the gold fingers function properly. The PCB design itself must also account for the required finger length and alignment areas to ensure proper connection. Regardless of the PCB’s size or purpose, the following rules apply universally when designing gold fingers:

- Via Holes Should Never Be Close to Gold Fingers

The positioning of via holes—used for electrical connections between layers—should never be placed near the gold finger areas. Placing vias too close to gold fingers can disrupt the electrical continuity and reliability of the signal transmission, making the connection unstable. - No Contact with Solder Mask or Silk Screen

Gold fingers should not come into contact with the solder mask or silkscreen layers. Both of these areas must be kept at a distance from the gold fingers to avoid short circuits or mechanical interference. The solder mask, designed to protect non-contact areas of the PCB from soldering, can damage the gold finger’s integrity if they are too close. - Gold Fingers Must Be Oriented Correctly

Gold fingers should always point in the opposite direction of the PCB’s center, unless specific angled edges are required. The orientation is crucial to ensure the gold fingers fit correctly into their respective connectors on the motherboard or peripheral devices. Incorrect orientation can lead to improper insertion or even mechanical damage to both the gold fingers and the connectors.

If any of the above guidelines are violated during the PCB design or plating process, the result could be failure in communication between the PCB and the main board, or improper installation into the motherboard’s corresponding slots. Such errors would significantly compromise the functionality of the entire electronic system.

Why Gold Is Used for PCB Gold Fingers

The choice of gold for PCB gold fingers is largely due to its exceptional conductivity, corrosion resistance, and durability. The conductive properties of gold make it an ideal material for high-precision electronics, as it facilitates fast and reliable signal transmission. Additionally, the robust nature of gold allows the gold fingers to withstand up to 1,000 insertion cycles without significant wear, ensuring that the connections remain intact even after frequent use.

You might wonder why gold is preferred over other metals, such as copper or nickel, especially given that gold is one of the rarest and most expensive natural elements. While it might seem more cost-effective to use copper or nickel plating for PCB connection edges, gold offers unmatched performance in terms of longevity and reliability, making it indispensable for high-performance electronic systems.

Gold’s Unique Benefits for PCB Applications

As PCBs have evolved, gold has emerged as the most suitable metal for electrical contacts due to several key properties:

- Electrical Conductivity: Gold’s conductivity ensures that electrical signals pass efficiently through the gold fingers, minimizing resistance and reducing the risk of signal loss.

- Corrosion Resistance: Unlike other metals, gold is highly resistant to oxidation and corrosion. In environments where PCBs are exposed to moisture, dust, and varying temperatures, gold fingers will maintain reliable performance without degradation.

- Durability: To further enhance its strength, the gold used in PCB gold fingers is often alloyed with nickel or cobalt, which increases the hardness and abrasion resistance of the gold coating. This makes the gold fingers more resistant to physical wear, which is critical in applications where PCBs are frequently inserted and removed from slots.

Nickel Plating Thickness for Gold Fingers

For optimal performance, gold fingers are typically plated over a layer of nickel, which serves to improve adhesion and prevent the gold from wearing off too quickly. The thickness of the nickel layer used in the plating process typically ranges from 150 to 200 microinches (4-5 microns). This thickness ensures the gold layer adheres firmly to the copper traces on the PCB and provides additional durability.

The nickel underlayer also helps protect the PCB’s copper traces from corrosion, further enhancing the longevity of the connection points. The combination of nickel and gold creates a strong, conductive, and corrosion-resistant surface that ensures reliable performance throughout the life of the product.

Gold fingers are a critical component in ensuring seamless communication and durable connections between PCBs and other system components. With their high conductivity, resistance to corrosion, and ability to withstand frequent usage, gold fingers are essential in many high-performance applications, from personal computers to industrial machinery. By adhering to proper design guidelines and using high-quality materials, manufacturers can ensure that gold fingers function as intended, offering reliable and long-lasting connections for years to come.

PCB Gold Finger Bevel: A Critical Design Consideration

In the PCB (Printed Circuit Board) manufacturing process, the gold finger plating procedure is typically carried out after the solder mask layer but before the final surface treatment. This sequence ensures that the gold finger connections are durable and reliable. The process of plating gold fingers involves several precise steps:

- Nickel Plating: The first step in the process is to plate a thin layer of nickel onto the connector edges of the PCB. This nickel layer, typically 3 to 6 microns thick, forms a strong bond between the copper base and the gold layer. The nickel also acts as a protective barrier, preventing the gold from diffusing into the copper beneath it.

- Gold Plating: Once the nickel layer is in place, a thin layer of gold, generally 1 to 2 microns thick, is applied over the nickel. Gold is preferred for its excellent conductivity and resistance to corrosion. To enhance the surface resistance and durability, cobalt is often alloyed with the gold during the plating process. This alloying improves the gold’s abrasion resistance, making it more durable under frequent insertion and removal.

- Beveling the Edges: After plating, the edges of the gold fingers are typically beveled at a specific angle to facilitate smooth insertion into their respective connectors. This beveled edge, usually angled between 30 to 45 degrees, allows for easier alignment and insertion into the slot, minimizing the risk of damaging the gold fingers during use.

Variations in Gold Finger Length

In some PCBs, the gold fingers may vary in length to accommodate the overall design and improve functionality. For instance, one end of the PCB may feature longer gold fingers to aid in easier insertion into a slot. By having a longer gold finger on one side, the PCB can more easily engage with the connector, after which the remaining portion of the PCB is simply pushed into place. This feature enhances the assembly and maintenance of the electronic device, ensuring that the connections are securely made and providing better alignment.

Design Constraints and Limitations

There are several critical design limitations when it comes to the gold finger plating process to ensure optimal functionality and longevity:

- Copper-Free Inner Edge: To avoid exposing copper during the beveling process, the inner layer of the PCB at the gold finger edge must be free of copper. This prevents the copper from being exposed when the edges are beveled at the required angle, which could result in electrical shorts or weakened connections.

- Clearance from Plated Vias, SMDs, and Pads: To avoid interference during the gold finger installation and ensure reliable electrical connections, plated vias, Surface-Mount Devices (SMDs), and pads must be located at least 1.0 mm away from the gold fingers. This ensures that there is no risk of short-circuiting or mechanical damage during the PCB’s assembly or usage.

- Length Limitation for Plated Pads: The length of plated pads near the gold finger edges should not exceed 40 mm. Exceeding this limit can cause issues during the insertion process or lead to mechanical failure due to the extended length of the pads.

- Distance Between Gold Fingers and PCB Outline: It is also essential to maintain a minimum 0.5 mm distance between the gold fingers and the PCB’s outer profile. This spacing ensures that the gold fingers are properly protected and that the PCB can be inserted into the slot without risk of misalignment or mechanical damage.

- Standard Spacing Tolerances: Any deviation from the standard spacing requirements around the gold fingers can result in the degradation of the physical and functional performance of the PCB. For instance, incorrect spacing can lead to poor signal transmission, increased wear and tear on the gold fingers, or even complete failure to connect with the motherboard’s slot.

The design and manufacturing of PCB gold fingers are integral to ensuring the reliable and efficient functioning of electronic devices. From the precise plating process involving nickel and gold to the careful beveling of the connector edges, each step is critical in producing durable, high-performance gold fingers. By adhering to strict design guidelines and maintaining precise spacing and alignment, manufacturers can ensure the PCB gold fingers will provide long-lasting, reliable connections, capable of withstanding frequent use in both consumer electronics and industrial machinery.

Ending

As manufacturers strive to push the boundaries of speed and resource efficiency, both computers and mobile devices have become increasingly sophisticated. In a modern computing environment, whether it’s a large data center or a vast network of mobile devices, multiple gold-plated circuit boards are constantly interacting with one another. Every time you print a document or upload a photo to social media, signals are transmitted from peripheral devices to the motherboard, which in turn processes these signals through the PCB.

Much of the technological progress we’ve seen today, where millions of people rely on mobile devices and advanced computing systems daily, can be attributed to the role of gold fingers. These vital components ensure smooth and reliable connections, enabling data flow between various devices and systems. The widespread use of gold fingers has not only made consumer technology more powerful but has also boosted efficiency across countless industries.

As technology becomes even more reliant on PCB gold fingers, ensuring that these components are plated and tested to the highest standards is essential. Only through rigorous testing and precision manufacturing can you guarantee that the devices utilizing these circuit boards deliver optimal performance. At CustomPCBA, we are committed to providing the highest-quality PCBs for a wide range of industries.

For reliable, high-performance circuit boards that meet your specifications, get in touch with us today for a free quote. Let us help you power your next innovative project.