In today's electronic devices, printed circuit boards (PCBs) are an essential component that plays a critical role in the functioning of almost every device. Whether it’s a smartphone, computer, television, or industrial control system, the PCB is at the heart of these products, providing both mechanical support for electronic components and the electrical connections that enable them to work together. As technology continues to advance, PCB design and manufacturing have become increasingly complex, requiring not only efficient electrical performance but also higher levels of integration and smaller form factors.

As the "brain" of electronic products, PCBs house a variety of components—such as resistors, transistors, capacitors, and more—that collaborate to ensure the smooth flow of electricity and the proper functioning of electronic systems. But how do these circuit boards actually work? What key components make them function? In this article, we will explore the basic principles of PCB operation, its essential components, and its vital role in modern electronic devices. Understanding how PCBs function will provide you with a deeper appreciation of their irreplaceable role in today’s technology.

Working Principle and Components of a PCB (Printed Circuit Board)

A Printed Circuit Board (PCB) is an indispensable component in modern electronic devices. Whether it's a smartphone, computer, home appliance, or industrial control system, the PCB provides support and connection for the electronic components. It not only offers mechanical support but also acts as a platform for electrical connections between components, forming the backbone that ensures the proper functioning of electronic products.

Basic Working Principle of a PCB

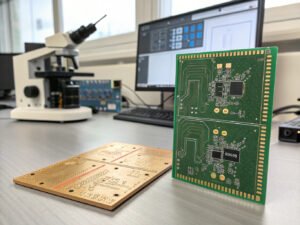

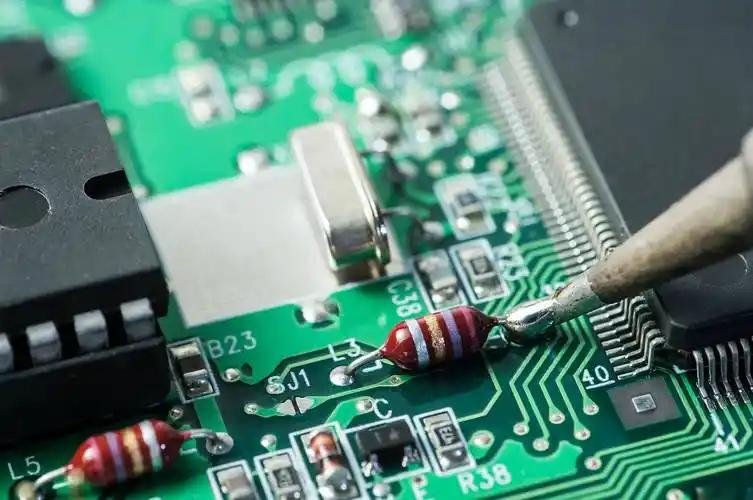

The core function of a PCB is to connect electronic components and ensure the transmission of electrical signals between them. PCBs are typically made from a plastic material reinforced with fiberglass, which offers both excellent electrical insulation and sufficient mechanical strength. Electronic components are fixed onto the PCB by soldering, and electrical connections are made through copper traces, allowing current to flow between the components and enabling the entire circuit system to function.

In PCB design, traces (also known as circuit paths) play a crucial role. These traces allow current to flow from the power source through various electronic components, ultimately enabling the functionality of the electronic product. Additionally, PCBs have many small holes where the leads of the electronic components are inserted and fixed. These holes are precisely drilled during manufacturing to ensure a solid electrical connection between the components and the circuit.

Single-Sided and Double-Sided PCBs

A single-sided PCB is the most basic form, with one side covered by a copper layer and the other side used for mounting electronic components. These PCBs are typically used in applications with simple circuits and compact designs.

A double-sided PCB has copper layers and component mounting on both sides of the board. By drilling holes and using vias (electrical connections through the board), it can electrically connect the top and bottom layers, enabling more compact and complex wiring designs. Double-sided PCBs are commonly used in applications requiring more functionality in a smaller space, such as portable devices and advanced electronic products.

Key Components of a PCB

Each PCB contains several essential electronic components that work together to ensure the board operates properly and effectively transmits power or energy. Here are some of the key components commonly found on PCBs:

- Resistors: Resistors are one of the most common components on PCBs. They regulate current and control the voltage by dissipating electrical energy as heat. Resistors help protect circuits by preventing excessive current that could cause damage.

- Transistors: Transistors are used to amplify or switch electrical signals and are indispensable in modern electronic circuits. They control the flow of current to alter the state of the circuit and are widely used in signal processing, computing, and control applications.

- Capacitors: Capacitors store electrical energy and release it when needed. They stabilize the circuit's voltage, playing a key role in power management systems by smoothing voltage fluctuations.

- Inductors: Inductors store energy in the form of a magnetic field and are commonly used in filtering circuits. They help reduce high-frequency noise and electromagnetic interference (EMI), making them useful in power supplies, signal processing, and other systems.

- Diodes: Diodes allow current to flow in one direction only, preventing reverse current that could damage the circuit. They are widely used for circuit protection, preventing overvoltage, and blocking reverse current.

The Complexity of PCB Design and Manufacturing

Designing and manufacturing PCBs involves considering multiple factors, such as component layout, signal integrity, electromagnetic compatibility, and thermal management. Modern PCB designs need to meet not only electrical performance standards but also considerations for material selection, mechanical strength, and manufacturing cost.

For example, multilayer PCBs build upon single-sided or double-sided PCBs by adding multiple layers of circuits. This design significantly increases the circuit density, allowing more complex circuits to fit into limited spaces. Multilayer PCBs are commonly used for high-frequency signal transmission, integrated circuits, and complex digital devices.

How We Can Help You

At custompcba, we specialize in providing high-quality, precision PCB design and manufacturing services. Whether you need single-sided, double-sided, or multilayer PCBs, we can provide tailor-made solutions based on your requirements. Our expert team has extensive experience in all aspects of PCB production, from circuit design, component selection, and prototype creation to mass production.

No matter if your project involves consumer electronics, industrial control, or medical devices, we can offer efficient and reliable PCB solutions. We are committed to helping our clients reduce product development costs, shorten R&D timelines, and ensure that each PCB meets industry standards for quality and performance.

If you have any questions about PCB design and manufacturing or would like to learn more about how we can assist you with your project, feel free to contact us. We look forward to working with you to help drive your project to success.