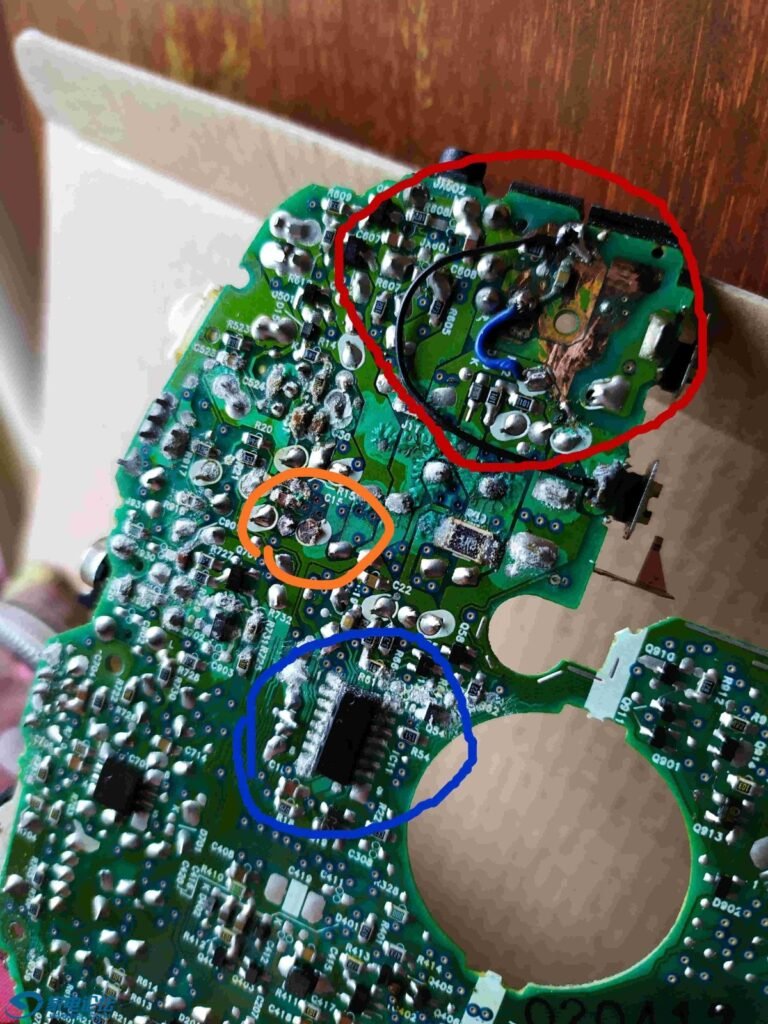

Circuit boards are the heart of most electronic devices, such as smartphones and smart TVs, playing a crucial role in their speed and performance. However, circuit boards can sometimes accumulate dust or suffer from corrosion due to various unavoidable factors, which can negatively impact the device’s overall function.

Corrosion on a circuit board not only weakens the performance of the device but, in severe cases, can lead to permanent damage. That’s why it's essential to learn how to remove corrosion from circuit boards using simple and effective methods.

Today, we’ll guide all electronic device users through easy steps for cleaning circuit boards, sharing the quickest and most convenient tips for corrosion removal. Additionally, we’ll discuss common causes of circuit board corrosion and offer prevention tips to help you better maintain your devices.

Are you ready to get started? Let’s dive in!

Causes of Circuit Board Contamination and Corrosion

Although circuit boards are often located inside the devices, they are not immune to contamination and dirt. In fact, this is quite common. Nearly all electronic devices have small vents that allow air to enter the device. This airflow not only helps cool the components but also carries dust, debris, and other contaminants into the device, accumulating on the circuit board over time. These particles and residues can cause the circuit board to become dirty and, when combined with moisture, can lead to corrosion.

In addition, larger devices often use fans to prevent overheating, but these fans also contribute to the accumulation of dust and dirt on the circuit boards, making them more prone to contamination.

Two types of contaminants commonly lead to circuit board corrosion:

- Dry Contaminants: Dust and debris are the most common dry contaminants that make circuit boards dirty. They accumulate through the air and are generally easier to clean.

- Wet Contaminants: These include substances like soldering flux, grease, dirt, and even spilled liquids. Wet contaminants can cause more severe corrosion and require different cleaning methods to prevent permanent damage to the circuit board and components.

Causes of Circuit Board Corrosion

Before diving into how to remove corrosion from a circuit board, it’s important to understand what causes this corrosion. Identifying the contributing factors can help you take preventive measures to avoid buildup in the first place.

Many chemicals naturally float in the air, even in clean environments. Over time, the metals in circuit boards, such as aluminum and copper, can react with these airborne chemicals, leading to corrosion. Additionally, liquid spills, whether from external sources or internal leaks, are also common causes of corrosion. No matter the source, the result is often rusting, which impairs the board's functionality.

The primary consequences of corrosion include:

- Rusting of the metal components, which reduces the electrical conductivity of the board.

- Short circuits caused by the conductive nature of the corrosion, which can eventually lead to permanent damage to the device.

How to Effectively Remove Corrosion from Circuit Boards

There are several cleaning solutions available to address corrosion, depending on the severity of the damage. Below are some common chemical and non-chemical methods for cleaning circuit board corrosion, along with a step-by-step guide for restoring the board to its proper functioning.

Safety Precautions

Before attempting to clean corrosion from a circuit board, it’s essential to follow these safety guidelines:

- Power Off the Device: Ensure the device is disconnected from any power source to avoid electrical shock during cleaning.

- Remove the Battery: If the device contains a battery, remove it and place it in a safe area.

- Avoid Water Contact: During cleaning, do not let water come into contact with the circuit board. Ensure your hands and cleaning materials are dry.

- Wear Gloves: If using chemicals like isopropyl alcohol, it is recommended to wear gloves to protect your hands.

- Handle with Care: Circuit boards and their components are fragile. Be gentle to avoid damaging any parts during the cleaning process.

Common Cleaning Tools and Chemicals

- Compressed Air: For routine maintenance, compressed air is an excellent tool to clear dust and small debris from the circuit board. The high-pressure air can effectively remove most dry contaminants and a small amount of rust.

- Baking Soda: Baking soda, or sodium bicarbonate, is a common and effective cleaner. It can break down dirt and grime on the circuit board, making it easier to clean. It is typically mixed with distilled water to form a paste.

- Distilled Water: If liquid is necessary for cleaning, always use distilled water. It is free from harmful minerals and impurities that can cause further corrosion on the board.

- Isopropyl Alcohol: Isopropyl alcohol is a widely-used cleaner for removing debris, flux, dust, and corrosion from circuit boards. It should only be used as a last resort when other cleaning methods like distilled water or baking soda are ineffective. Ensure that the alcohol is at least 90% purity for optimal results.

Step-by-Step Process for Removing Corrosion from Circuit Boards

- Disassemble the Device: Begin by following the user manual to safely disassemble the device and access the circuit board. Take clear pictures of the assembly before disassembly to help with reassembly later.

- Initial Cleaning: Use compressed air or a baking soda mixture to clean off dust and mild corrosion. Mix half a cup of distilled water with 1-2 tablespoons of baking soda to form a paste. Apply the paste to the corroded areas with a soft brush, allowing it to sit for a few minutes to soften the debris. Gently scrub the board with the brush.

- Use Isopropyl Alcohol for Stubborn Corrosion: For more severe corrosion, drop a few drops of isopropyl alcohol directly onto the affected areas. Let it sit for 15-20 seconds, then gently wipe away the corrosion with a microfiber cloth or brush. Repeat the process if necessary.

- Dry the Circuit Board: After cleaning, it’s crucial to dry the circuit board thoroughly. Use a blow dryer or heat gun to remove any remaining moisture. Be patient—this may take several minutes to ensure that the board is fully dry and free of any residual cleaning solution.

Conclusion

Removing corrosion from a circuit board requires a combination of chemical and non-chemical solutions to effectively clean dirt, debris, and rust. Compressed air can be used for routine maintenance, while more stubborn corrosion may require baking soda, distilled water, or isopropyl alcohol. The key to successful cleaning is to follow a careful, step-by-step process, ensuring the board is completely dry and free from harmful contaminants. Preventing moisture buildup is crucial to avoid future corrosion, as it is one of the leading causes of PCB damage.