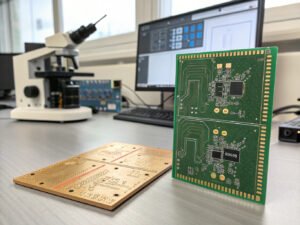

The standard thickness of a printed circuit board (PCB) is often considered to be 0.062 inches (1.6 mm), or 1/16 inch, with a manufacturing tolerance of ±10%. This thickness has become the industry norm due to its historical roots, as early PCB designs were based on the size of Bakelite or phenolic boards, which typically measured 0.062 inches thick. As a result, this thickness remains one of the most widely used standards in PCB manufacturing today.

While 0.062 inches is the most common PCB thickness, it is far from the only one used in electronic assemblies. Depending on the application and specific requirements of the design, various other thicknesses are frequently used, each catering to different mechanical, electrical, and thermal performance needs.

Common PCB Thickness Variations

- 0.031 inches (0.8 mm)

A thinner option than the standard 0.062 inches, 0.031-inch thick PCBs are often used in applications where space is constrained or where weight reduction is critical. These thinner boards are commonly found in compact consumer electronics, mobile devices, and other portable equipment, where size and weight are key considerations. Despite their reduced thickness, they still provide sufficient mechanical strength and electrical performance for many applications. - 0.093 inches (2.4 mm)

On the other end of the thickness spectrum, 0.093-inch thick PCBs are frequently used in designs that require more durability, especially when the PCB needs to support heavy components or higher mechanical stress. These boards are common in automotive electronics, industrial control systems, and multi-layer circuit boards where additional strength and resistance to environmental factors are necessary.

Other PCB Thickness Considerations

Beyond the standard thicknesses, custom PCB thicknesses are available to meet specific design and performance requirements. Factors such as the number of layers, component density, and thermal management needs can influence the choice of PCB thickness. Some applications may require very thin or very thick PCBs, depending on the overall design goals, and PCB manufacturers often provide custom options to accommodate these needs.

- Thin PCBs (below 0.031 inches) are typically used in applications requiring lightweight and ultra-compact designs, such as in wearables, medical devices, and IoT devices.

- Thicker PCBs (above 0.093 inches) are used when high mechanical strength is required, such as in military equipment, automotive sensors, or power electronics, where components may experience high vibration, heat, or external forces.

Factors That Influence PCB Thickness Selection

When selecting a PCB thickness, several key factors must be considered to ensure the board meets the performance and reliability requirements of the end product:

- Mechanical Stress: Thicker PCBs provide more robust mechanical support, making them ideal for applications where the PCB will be exposed to physical stress or vibration.

- Thermal Management: Thicker PCBs tend to offer better heat dissipation, which is crucial in high-power applications such as power supplies or high-frequency circuits.

- Component Density: Thinner PCBs are often used when space constraints are tight, as they allow for more compact designs and increased component density in smaller enclosures.

- Manufacturing Process: The thickness of the PCB can also affect the manufacturing process and cost. Thicker boards may require additional processing steps, such as deeper vias or additional copper plating, which can increase the complexity and cost of production.

- Electrical Performance: While the thickness of the PCB itself does not directly affect electrical performance, it does influence factors like trace width and current carrying capacity. A thicker PCB may support wider traces or higher current loads, which is critical for power electronics and high-speed circuit designs.

Factors Affecting PCB Thickness: Design and Manufacturing Considerations

The final thickness of a PCB (Printed Circuit Board) is influenced by both design factors and manufacturing capabilities. While design considerations focus on the functional and performance requirements of the PCB, manufacturing factors address the practical constraints of production. Below are the key factors that affect PCB thickness from both design and manufacturing perspectives.

Design Factors

- Size, Weight, and Flexibility Requirements

- Thin PCBs offer advantages in weight reduction and flexibility, making them ideal for applications where size and weight constraints are critical, such as in portable electronics and wearable devices. However, thinner boards are more fragile and can be prone to breakage, so they are best suited for flexible PCBs (FPC) that require bendability.

- In contrast, thicker PCBs provide greater mechanical strength, making them suitable for high-strength or industrial-grade applications, such as automotive electronics and high-power devices. However, thicker boards increase the overall weight and volume, which may not be ideal for designs where space and weight are limited.

- Copper Thickness

- The copper thickness directly influences the overall thickness of the PCB. Copper layers are typically chosen based on the current carrying requirements of the PCB. Standard copper thicknesses range from 1 oz to 2 oz per square foot (approximately 35μm to 70μm). However, for high-power applications or high-frequency circuits, thicker copper layers may be required.

- Increasing copper thickness not only increases PCB thickness but also impacts manufacturing cost due to the added complexity of processing thicker copper.

- Material Selection

- The substrate material (such as epoxy resin fiberglass (FR4), ceramic substrates, etc.) plays a significant role in the PCB's thickness. The mechanical properties, thermal conductivity, and dielectric constant of the material directly influence the final thickness of the PCB. For example, ceramic substrates typically result in thicker PCBs, offering better thermal management for high-frequency and high-power applications.

- Laminate materials—which consist of layers of resin and paper or cloth—also determine PCB thickness. The compression of these laminate layers affects the overall thickness of the board, as well as the electrical and thermal properties.

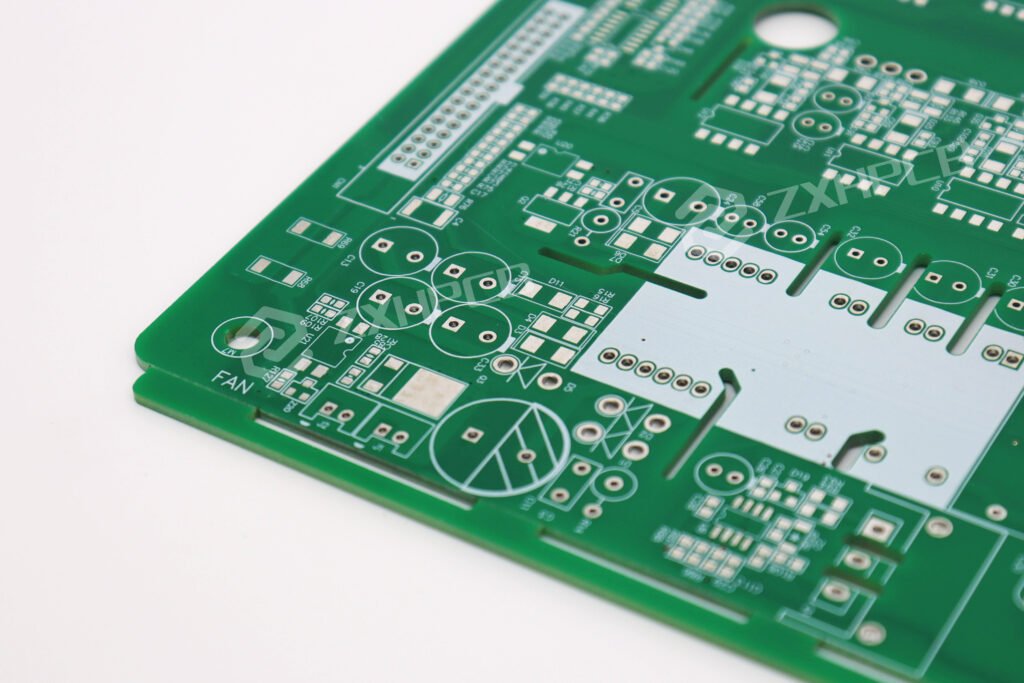

- Number of Layers

- The number of layers in a PCB directly impacts its thickness. A 2- to 6-layer PCB typically falls within standard thickness ranges (e.g., 0.062 inches), but 8 or more layers will require additional thickness due to the stacking of layers. In such cases, the board's final thickness will increase, and the design needs to account for this increase, especially when multi-layer designs are necessary for signal integrity, power distribution, and thermal management.

- Signal Types and Power Requirements

- The type of signals the PCB will carry plays a role in determining its thickness. For high-power signals, thicker copper and wider trace widths are required, leading to a thicker board. Conversely, high-density interconnect (HDI) boards for high-frequency or high-speed digital signals typically use thin copper layers, fine traces, and advanced materials, which result in thinner boards to ensure compactness and high signal integrity.

- Via Types and Density

- The type of vias used (e.g., blind vias, buried vias, microvias) can significantly impact PCB thickness. Microvias and buried vias are commonly used in HDI designs and can allow for thinner PCBs, as they occupy less space and allow for higher-density interconnects. In contrast, traditional through-hole vias may require thicker boards, especially if the PCB has multiple layers.

- Environmental and Thermal Considerations

- The thickness of the PCB and the materials used will affect its thermal conductivity and resistance. Thin boards or flexible boards may not be suitable for harsh or high-temperature environments, where thicker boards are often required to maintain structural integrity and improve heat dissipation.

- Thicker copper in PCBs used in high-current applications improves the thermal stability and current handling capacity, which is essential in power electronics or automotive systems. Thus, the environmental conditions in which the PCB will operate heavily influence the desired thickness.

Manufacturing Factors

- Drilling Equipment and Capabilities

- The drilling process adds complexity to PCB manufacturing, especially when drilling holes in thicker boards. Manufacturers are limited by their equipment’s ability to drill precise holes, and the ratio between hole depth and hole diameter (known as the aspect ratio) becomes more critical in thicker boards. For standard holes, a 7:1 aspect ratio is typical, but for thicker boards, the ability to drill small holes may be reduced, which can complicate designs with high-density vias.

- Manufacturers with specialized laser drilling or precision milling capabilities can handle smaller hole diameters and deeper holes, but such techniques usually come at a higher cost.

- Copper Thickness and Etching Process

- The copper layer thickness affects the etching and plating processes during PCB manufacturing. Thicker copper layers are more difficult to etch and may require additional processing steps. The increased copper thickness also affects the board's current handling capability, but this comes with added production complexity and cost.

- Number of Layers and Manufacturability

- As mentioned, increasing the number of layers in a PCB increases its overall thickness. While professional manufacturers can produce multi-layer boards with precise thickness tolerances, this comes with higher costs due to more complex fabrication processes. A multi-layer board may require additional alignment and lamination steps, which further influence the final thickness of the PCB.

- Panelization and Depanelization Methods

- Panelization involves producing multiple PCBs on a single panel before separating them into individual boards. The thickness of the PCB affects the panelization process. Thicker PCBs might require scoring or laser cutting during depanelization, while thinner boards may be separated by routing. The method of depanelization must be chosen to suit the thickness and material properties of the PCB to avoid damage during the cutting process.

Three Critical Factors to Consider When Choosing PCB Thickness

When selecting the optimal PCB thickness for your application, it is essential to weigh several key factors that influence both performance and cost. While many designers opt for standard PCB thicknesses due to their proven performance and cost-effectiveness, others may require custom thicknesses to meet specific functional requirements. Below are three crucial factors to consider when deciding between standard or custom PCB thickness:

1. Manufacturing Capabilities

- The first and most crucial consideration is whether your chosen PCB manufacturer has the necessary capabilities to produce the required thickness. Different thicknesses, particularly custom ones, often require specialized manufacturing processes and equipment settings that not all manufacturers can accommodate. For instance, some designs may require advanced techniques, such as high-density interconnects (HDI) or multi-layer designs, which demand precise lamination, fine drilling, and laser cutting for thinner or more intricate designs.

- Manufacturers with advanced capabilities can accommodate more customized designs, but it's important to recognize that the more complex the requirements, the higher the cost. Engaging with the manufacturer early in the design phase will ensure they can meet your specific needs. Additionally, advanced processes may not only raise production costs but also introduce tighter tolerances for thickness, which can affect overall project feasibility and budget.

2. Lead Time and Production Delays

- Lead time is another essential factor when selecting PCB thickness. Standard PCB thicknesses (such as 0.062 inches or 1.6mm) are well-established in the industry and can be produced with minimal adjustments to the manufacturing process. In contrast, custom thicknesses typically require more time for the manufacturer to adjust their equipment and processes to meet the specific design needs.

- Any changes to PCB thickness—especially those outside common industry standards—can lead to longer lead times, as manufacturers may need to reconfigure machinery, adjust production lines, or use additional processes such as multi-step lamination or specialized etching techniques. More complex designs, such as those requiring additional layers or unique materials, will only add to the timeline. To avoid delays, it is essential to consult with the manufacturer early and request a time estimate for custom designs to ensure that your production schedule aligns with your business’s requirements.

3. Cost Implications

- The cost of manufacturing a PCB is directly impacted by its thickness. While standard thickness boards benefit from established manufacturing processes that are cost-efficient, custom thicknesses often incur higher manufacturing costs due to the need for specialized equipment, longer production times, and more complex processes.

- For instance, thicker PCBs may require more expensive materials or additional copper plating, while thinner boards could necessitate advanced microvia drilling or precision etching to ensure the integrity of the design. Additionally, custom boards may require changes to panelization methods, further increasing production complexity and cost.

- It’s important for businesses to perform a thorough cost-benefit analysis to determine if the added expense of a custom PCB thickness is justified by the functional advantages. In many cases, choosing standard thicknesses may offer a more affordable solution, provided they meet the performance and design requirements. However, for high-performance applications where custom thicknesses are necessary, the extra cost may be a reasonable tradeoff for the desired functionality or space optimization.

Conclusion

When choosing the optimal PCB thickness, it is essential to balance performance, manufacturability, lead time, and cost. Early consultation with your manufacturer about their capabilities, production schedules, and cost structures can help you make informed decisions about whether to go with a standard or custom thickness. While custom thicknesses offer flexibility for specialized designs, the associated costs and extended lead times must be carefully considered to ensure they align with your project’s timeline and budget constraints.