In today’s fast-paced business environment, maintaining product quality while improving operational efficiency is a challenge. The traditional supply chain process has been redesigned to create a complex system that covers everything from warehousing and production testing to distribution and transportation. We are based on transparency, efficiency and economy to meet your unique business needs.

Reduce warehousing costs to solve all your problems. With our system integration, you can enjoy the convenience of completed builds and components stored for you, while monitoring inventory data in real time and optimizing forecasts. Our state-of-the-art testing and inspection facilities ensure high quality production. For distribution and transportation, you can trust the warehouse we manage. MacroFab is committed to providing cost-effective solutions to meet your business needs.

With our online platform, you can easily manage all your inventory information centrally. Use in-depth analysis of key performance indicators to identify opportunities to improve products, create more value, and gain an edge over the competition. Our product lifecycle management support will help you respond effectively to the end of the lifecycle of critical components and improve design efficiency.

Our artificial intelligence algorithms will find the best production line for your project, optimizing production efficiency and quality to ensure project success. Enjoy the benefits of strong project management without heavy administrative tasks. MacroFab is committed to providing you with excellent service to make your job easier.

We offer a variety of flexible packaging and fulfillment options to help you get your products to your customers faster. Take advantage of our retail packaging services and eliminate the need to sign contracts with other distributors. With MacroFab, you can focus on creating great products and let us take care of everything else.

PCB assembly involves installing electronic components onto bare boards through assembly and welding techniques, resulting in a fully functional PCBA board. Precise board assembly is essential to achieve the intended function, which includes precise component placement and precise soldering. Even a minor error, such as a misplaced resistor or a small cut in the wiring, can cause assembly to fail. To ensure the success of your project, it is vital to choose a reliable PCB assembly service provider like FS Technology.

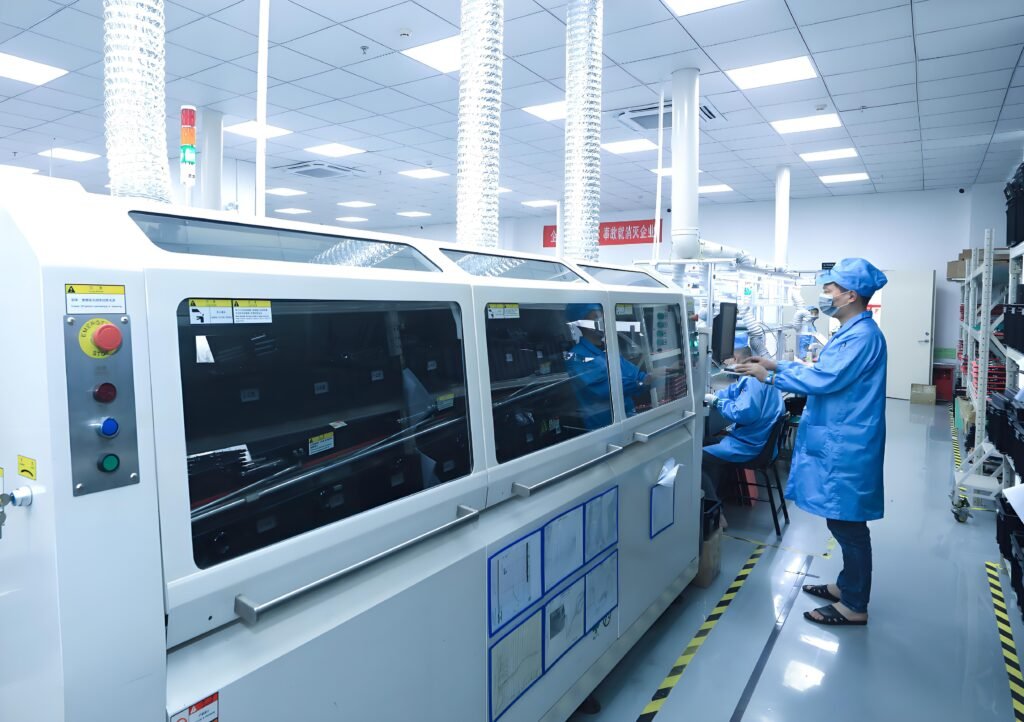

As a leading PCBA company based in Shenzhen, China, we focus on providing highly professional and comprehensive electronic assembly services for the electronics manufacturing industry. Our expertise and dedication to precision enable us to ensure the accuracy and reliability of your project. We invite you to contact us for a competitive PCB assembly quote and our team will assist you in a timely manner.

We source electronic components from globally renowned IC manufacturers such as Qualcomm, TSMC, DigiKey and Mouser to ensure they are original and authentic for our PCB electronic assembly. In the face of fluctuations in the parts market, we have our own management system and emergency plans. If you encounter a material shortage, our engineers will provide you with a cost-effective alternative for your review. In addition, we have a large capacity of component storage space to minimize the risk of global component shortages.

We source electronic components from world-renowned IC manufacturers such as Qualcomm, TSMC, DigiKey and Mouser, ensuring that these components are original and genuine PCB electronic assemblies. In the face of the chaotic parts market, we have our own management system and emergency plans. If materials are in short supply, our engineers will provide cost-effective alternatives for you to review. In addition, we have a large component storage space to minimize the risk of global component shortages.

The “turnkey” program refers to the full range of integrated services provided by EMS suppliers, covering the entire electronic assembly process from component procurement to final assembly and testing. In short, the customer only needs to provide the PCB design documents and specifications, and the rest of the work is solely responsible for EMS.

We offer full support and services from circuit design to product delivery. As a manufacturer with our own manufacturing and assembly shop, we are able to meet most of our customers’ needs, from prototyping to mass production, from manufacturing to assembly, from procurement to testing.

Turnkey PCB assembly services are ideal for customers who want to outsource the entire assembly process and provide a single point of contact for their electronics projects. This service model enables clients to save time on project management and focus resources on final sales and marketing.

A partial turnkey solution is a cost-effective PCB board assembly solution where the customer can choose to handle some aspects of the assembly process while the assembly company takes care of the rest. For example, customers can supply specific components, such as ics and main chips, while service providers are responsible for purchasing conventional components, such as inductors and capacitors.

Partial turnkey PCB assembly options are available for customers who have specialized or unique components, or who want greater control over the assembly process. This option is also an affordable option for customers who want to save on procurement costs for certain components. However, it should be noted that this option requires the assembly company to have sufficient purchasing and management experience, and requires more coordination, otherwise it may affect the overall quality of the project.

Work with multiple suppliers to manage orders and inventory using automated systems to reduce costs and improve response time.

Use intelligent systems to monitor production, optimize scheduling, prepare materials in advance, reduce stagnation and waste, and improve efficiency.

Use automated test equipment and data analytics to monitor quality in real time, solve problems quickly, and reduce rework and scrap.

Optimize transportation and warehousing and use tracking technology to monitor logistics status in real time to ensure on-time delivery and improve overall efficiency

We have 20 years of experience in the PCBA industry, specializing in electronic assembly services for the most demanding engineers and designers. They chose us as their business partner in China. Almost all of our customers have spoken highly of us, and this feedback comes from multiple sources, including our website, Alibaba platforms, and customer recommendations.

In this scheme, the customer is responsible for purchasing all the materials, we are responsible for the manufacturing and assembly of the PCB, and after the production is completed according to the customer’s requirements for testing. Through previous project experience, we have found that some clients rely on Hong Kong foreign trade service providers for procurement, even though their service quality is indeed good. However, this leads to unnecessary costs for the customer, as we are perfectly capable of providing these services.

In this case, it is assumed that the customer already has a stable and high-quality PCB manufacturer. The manufacturer is responsible for producing the bare panels and delivering them to us. We then procure and assemble the electronic components according to the documentation requirements provided by the customer.

With 20 years of experience in the PCBA industry, we know how to provide high-quality electronic assembly services to the most discerning engineers and designers. Our professional team is able to handle all kinds of complex projects, ensuring that every detail meets our clients’ high standards.

In addition to PCB manufacturing and assembly, we also provide comprehensive material procurement and logistics management services. This will not only help customers reduce procurement costs, but also improve overall efficiency. We are committed to providing customers with one-stop solutions to focus on the core business.

Our services have been widely recognized and almost all customers have given positive comments. The feedback comes from multiple sources, including official websites, Alibaba platforms and customer recommendations. We pride ourselves on customer satisfaction and constantly strive to improve the quality of our services.

We have the flexibility to adapt manufacturing and assembly processes to the specific needs of our customers. Whether it is small batch customization or mass production, we ensure that every project achieves the best results. Our goal is to provide our customers with tailor-made solutions that meet their unique needs.

We offer innovative material combinations capable of producing hybrid laminates of 4 to 10 layers, such as FR4 with Ro4350, FR4 with aluminum, and FR4 with FPC. Our technology can meet your needs for a wide range of complex material combinations.

Integrated service

We offer a full range of services including design, modification, manufacturing, assembly, testing, packaging, shipping and conformal coating. Whether you need prototypes, low-volume production, or large-scale production, we have the ability to provide you with high-quality solutions.

Manufacturing advantage

As one of the leading PCB manufacturing suppliers in China, we offer substantial production capacity at competitive prices and fast turnaround times. We offer turnkey and semi-turnkey services to provide our customers with flexible and convenient options.

Get a quote

Although we do not currently offer an online quotation service, we welcome you to contact the sales team by email. Our professional sales representatives will respond to your inquiry within 2 to 3 working days with a detailed price list.

4th floor,C building , High-tech International Innovation Center, Kelian Road, Yutang Street, Guangming New District, Shenzhen

long@custompcba.com

+86 18123721954