We are a leading supplier of PCBA solutions focused on high-end electronics manufacturers worldwide. With a wealth of expertise and resources, we are committed to providing outstanding quality service to our valued customers.

When dealing with electronic prototype projects, we know our customers’ strict requirements for impeccable quality and fast delivery. To meet these needs, we continuously invest in state-of-the-art equipment to ensure that projects are completed efficiently. In addition, we provide additional services such as design reviews, PCB testing and comprehensive quality control measures to ensure best-in-class results.

Thanks to our strong commitment to professionalism, many customers have made a smooth transition from prototype development to mass production. We look forward to the opportunity to provide you with a personalised offer and to impress you with our utmost dedication.

We carefully select components from reliable suppliers to ensure their functionality and reliability. At the same time, as part of our value-added services, we also offer cost-effective alternatives.

Before starting a prototype PCBA project, we conduct weldability tests to ensure safe connection of components to the board and reliable electrical performance.

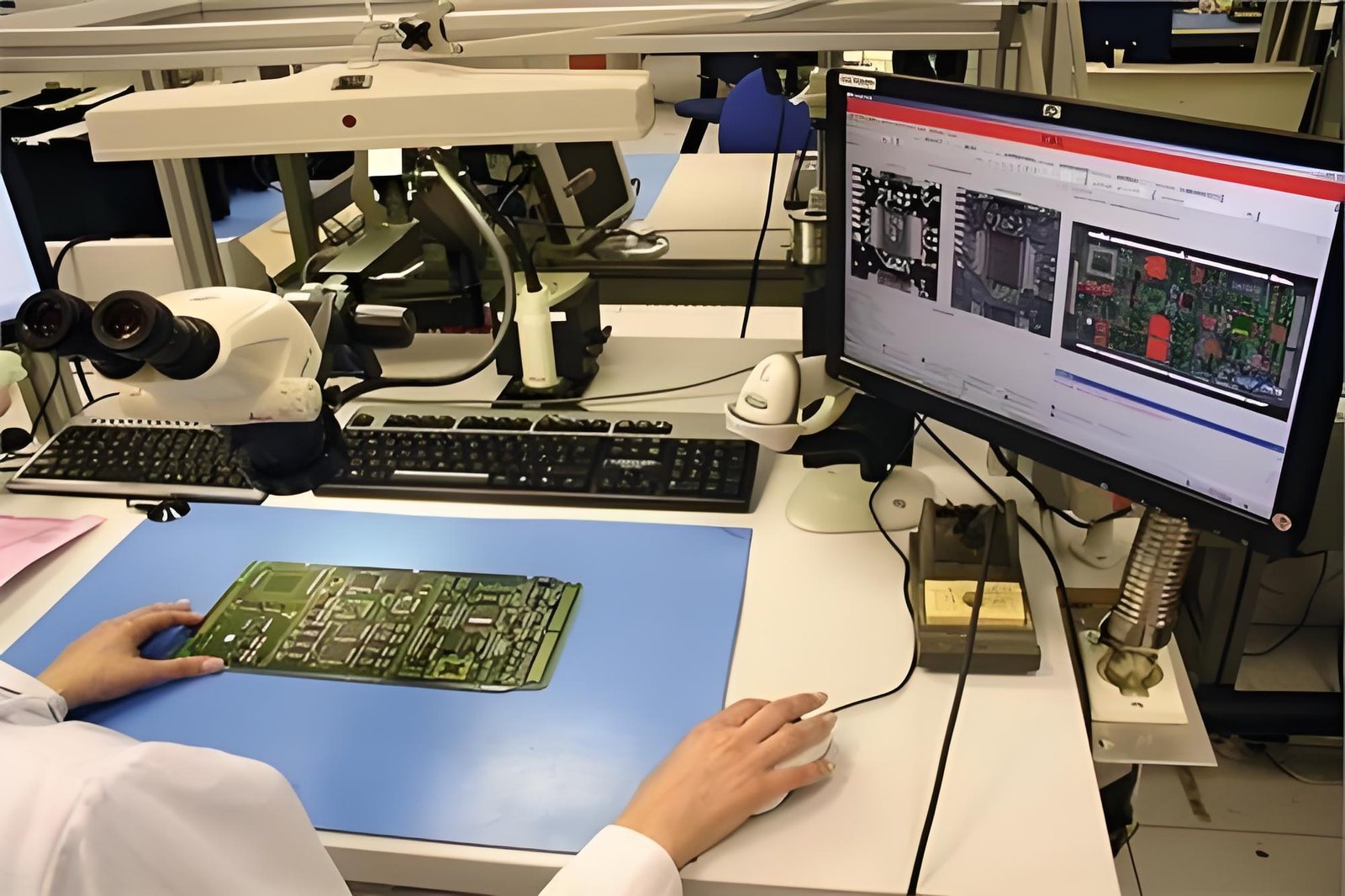

PCBA prototypes are thoroughly tested and validated to ensure optimal functionality after production.

From PCB board prototypes to PCBA prototypes, we always maintain detailed documentation for seamless replication and expansion in mass production.

As a B2B PCBA service provider with 20 years of industry experience, we can responsibly tell you that prototyping is usually more expensive than mass production. This is because prototyping requires a lot of manpower, material resources, transportation and time. These fixed costs are spread across each board, making the unit price for high-volume PCB assembly relatively low.

We offer competitive price advantage. With our own plants and large-scale material procurement capabilities, we are able to provide cost-effective solutions. Although we don’t offer free samples, our prices are significantly lower, ensuring you get your money’s worth.

Accuracy: In order to speed up the project, please provide your requirements and necessary documents (such as BOM, Gerber documents, etc.) directly when contacting us. Our technical team will immediately perform a Design for Manufacturability (DFM) analysis and provide you with a detailed PCB prototype quotation sheet.

Efficiency: We use a personalized 1-to-1 service model to ensure smooth communication and timely feedback and confirmation to our customers. Our account managers have direct access to manufacturing plants for effective project coordination with operators. In addition, our supplier network ensures the availability of the required information around the clock, minimizing latency.

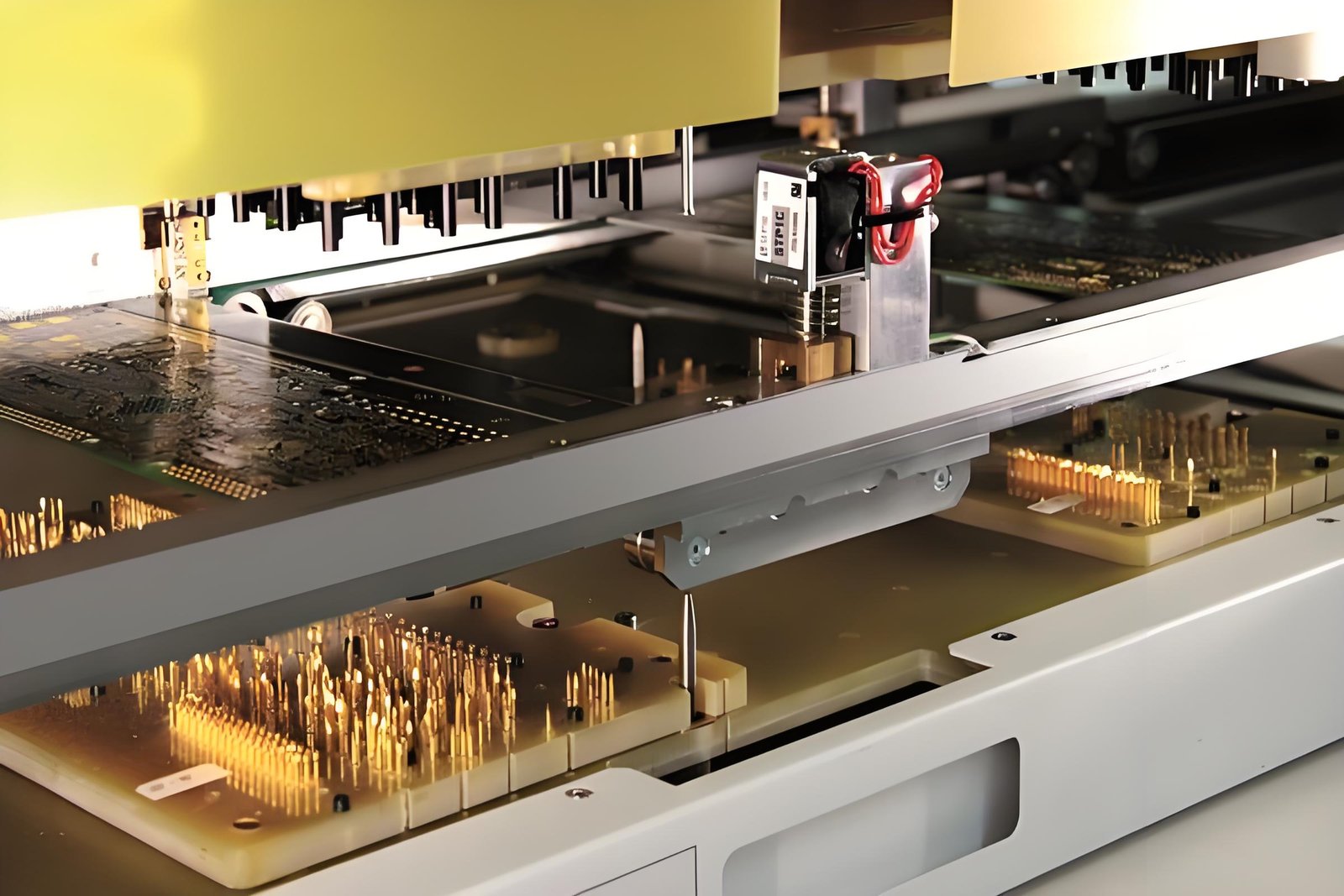

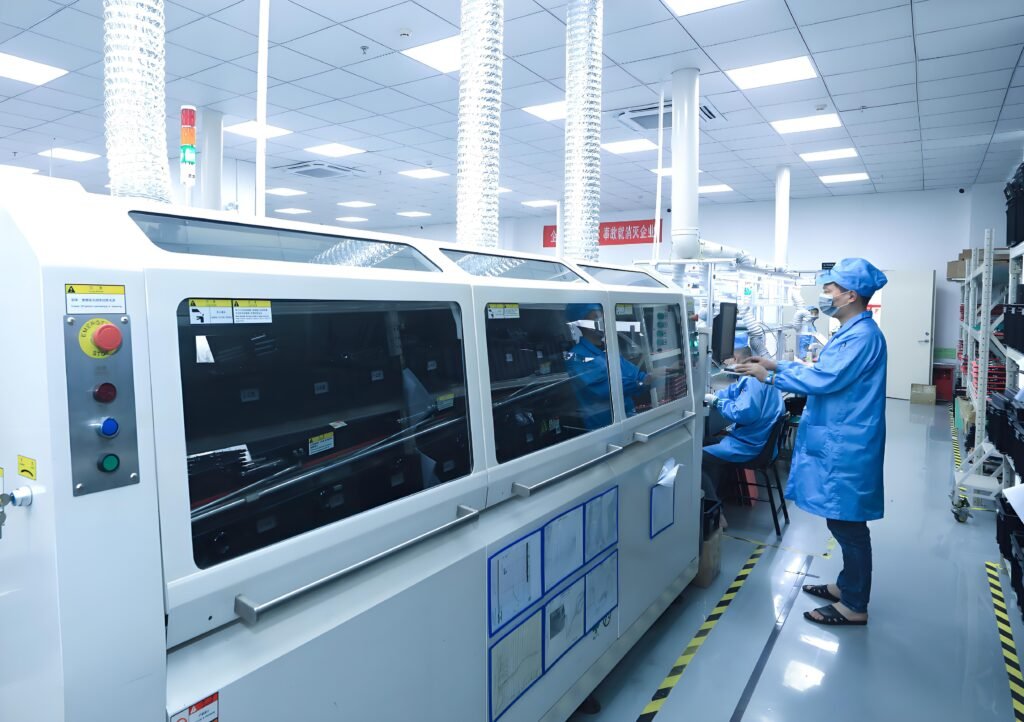

Scalability: We have two advanced manufacturing workshops equipped with 7 SMT and THT production lines, capable of handling multiple projects simultaneously. With a maximum production capacity of more than 5.2 million, we ensure efficient production and reduced project times for fast turnaround PCB assembly.

Experience: With 20 years of PCBA service experience, we have developed a robust management system that employs parallel workflows, allowing tasks to be executed simultaneously. This ensures rapid project progress while maintaining excellent quality standards.

When choosing a PCBA company, medical electronics manufacturers must be extra careful because their products are directly related to the quality of patient care, and the quality of the printed circuit board is critical to the performance of the medical device. Although industry giants like Foxconn are the first choice for many companies, their focus on high-volume production often limits the possibilities for collaboration. This highlights the importance of professional electronics manufacturing services like ours. It is important to note that not all PCBA companies are equipped to handle medical projects. In addition to technical expertise, certification such as ISO 13485 is also essential. It is this challenge that we have met.

In a previous case, a customer initially hired an OEM company to do a PCBA prototype design for a pacemaker. However, due to the lack of project management experience, the incorrect loading of materials during the assembly process hindered the progress of the project.

Recognizing the need for expertise, they turned to FS technology to ensure the success of prototype production. Our project management process begins with a comprehensive DFM analysis to identify any potential design issues. This approach optimizes circuit design, improves manufacturing efficiency, and ensures compliance with regulatory standards. Skilled operators assemble prototypes quickly using advanced automation equipment in our state-of-the-art assembly plant.

We understand the importance of precision and quality in medical electronics manufacturing. With our expertise, strict adherence to industry standards, and efficient project management, we have proven our ability to deliver high quality PCBA for medical applications.

Partner with us in your medical PCBA program to leverage our expertise, certifications, and commitment to excellence. Together, we can ensure that cutting-edge technologies are seamlessly integrated into medical devices to positively impact patient care.

The life cycle of a PCBA project typically includes prototyping, small batch orders, and large batch orders. Major electronics manufacturers impose strict requirements on their PCBA factories. Prior to high-volume PCB assembly, they may conduct factory inspections to ensure compliance with quality standards and regulatory requirements and mitigate any potential risk of delays.

A past case of working with a consumer electronics customer highlights the importance of caution when choosing suppliers. Despite the warnings, the customer chose a company that offered a lower quote for the prototype PCBA service on another website. Although the initial project went well, serious quality problems occurred during mass production, resulting in huge economic losses. Eventually, customers came to us.

In the early stages of working with us, the customer expressed a strong desire for a factory inspection to assess our capabilities. An intermediary service company in Hong Kong assisted the client with a visit to the FS Technology factory and a comprehensive understanding of our quality control process.

During the visit, the customer team was impressed by the impeccable cleanliness of our plant, the use of state-of-the-art equipment, and the high level of organization and efficiency observed throughout the assembly process. They were impressed by our rigorous quality control measures, such as AOI, ICT and functional testing, which guarantee that each product meets the required specifications and standards.

After the inspection was completed, the electronics manufacturer expressed satisfaction with the results and decided to continue working with FS Technologies as their trusted PCB assembly supplier. They have confidence in our ability to deliver high quality products and appreciate our meticulous attention to detail and unwavering commitment to maintaining standards of excellence. This gives them a sense of security, assuring them that future delays or financial losses will be effectively mitigated.

4th floor,C building , High-tech International Innovation Center, Kelian Road, Yutang Street, Guangming New District, Shenzhen

long@custompcba.com

+86 18123721954