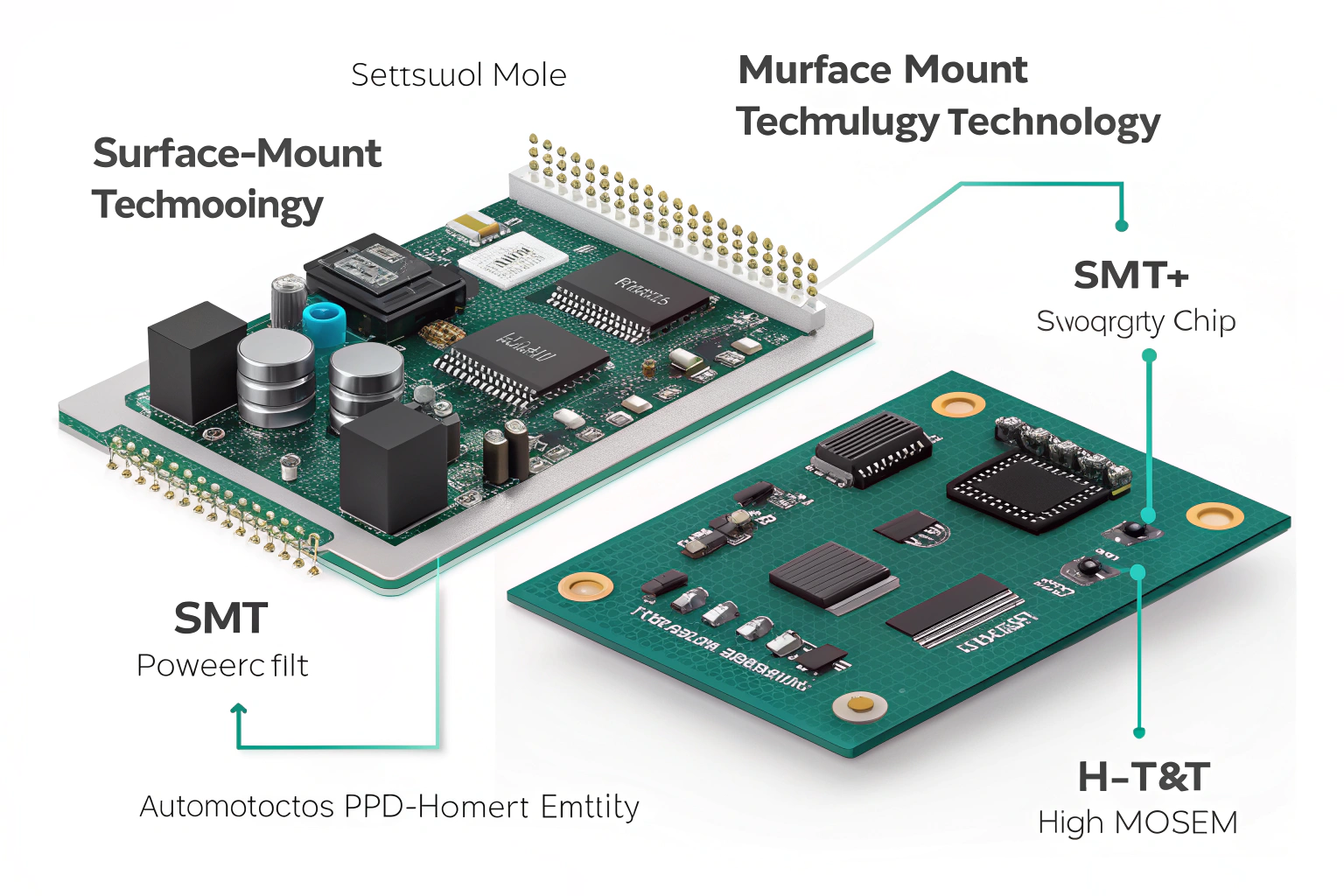

Surface Mount Technology (SMT) is the foundation of today’s electronic manufacturing. It allows components to be mounted directly onto the surface of a PCB instead of using through-holes.

SMT offers major advantages such as smaller size, higher assembly speed, and better performance, but it also brings challenges like complex rework, higher equipment costs, and strict process control requirements.

Understanding both the pros and cons helps engineers and product designers make better decisions for their PCB assembly strategy. Let’s explore how SMT impacts design, manufacturing, and product reliability.

What is SMT and how does it work?

SMT (Surface Mount Technology) is a process where electronic components are soldered directly onto PCB pads using solder paste and automated reflow.

Unlike traditional through-hole assembly, SMT doesn’t require drilling component leads through the PCB. Components are placed by automated pick-and-place machines and soldered in a reflow oven. This makes the process faster, more accurate, and suitable for high-density designs. In our factory, SMT enables us to handle complex IoT, industrial, and communication boards efficiently while maintaining excellent quality control.

| Process Step | Description |

|---|---|

| Solder Paste Printing | Apply solder paste onto PCB pads |

| Pick and Place | Mount components precisely |

| Reflow Soldering | Heat to melt and solidify solder |

| AOI Inspection | Verify solder joint quality |

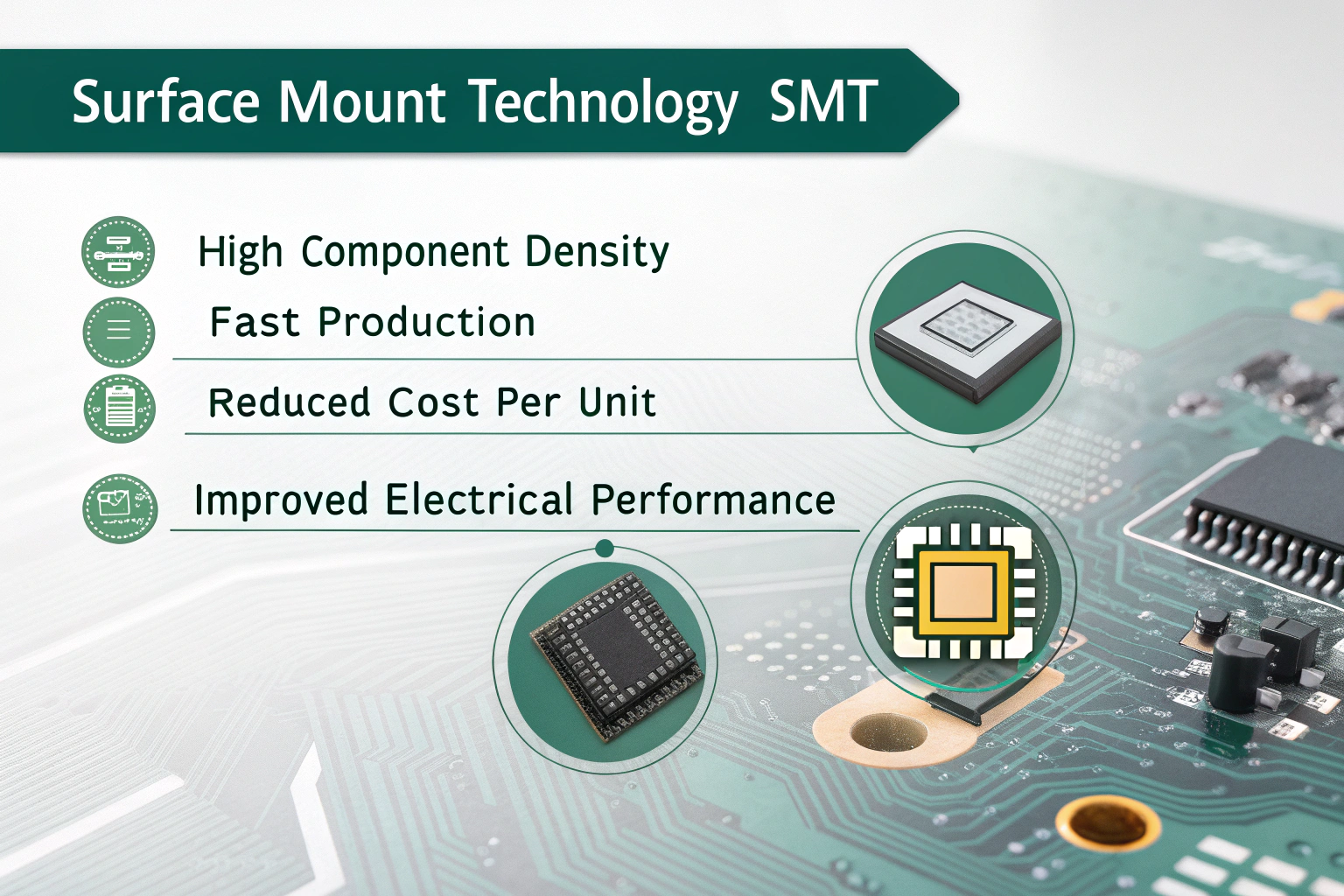

What are the main advantages of SMT?

The main advantages of SMT include high component density, fast production, reduced cost per unit, and improved electrical performance.

Surface mounting allows engineers to place more components on smaller boards, reducing product size and weight. Automated assembly improves production speed and consistency, minimizing human errors. Because of shorter lead lengths, SMT reduces parasitic inductance and resistance, improving high-frequency performance. In my factory, SMT helps customers achieve rapid prototyping and seamless scaling from small batches to mass production.

Key Advantages of SMT

| Advantage | Description |

|---|---|

| Compact Design | Smaller components for dense layouts |

| Fast Assembly | High-speed placement machines |

| Better Electrical Performance | Shorter connections reduce noise |

| Lower Labor Cost | Automation replaces manual insertion |

| Stronger Mechanical Bonds | Solder joints withstand vibration |

SMT has enabled the entire electronics industry to produce smarter, more portable, and more affordable devices.

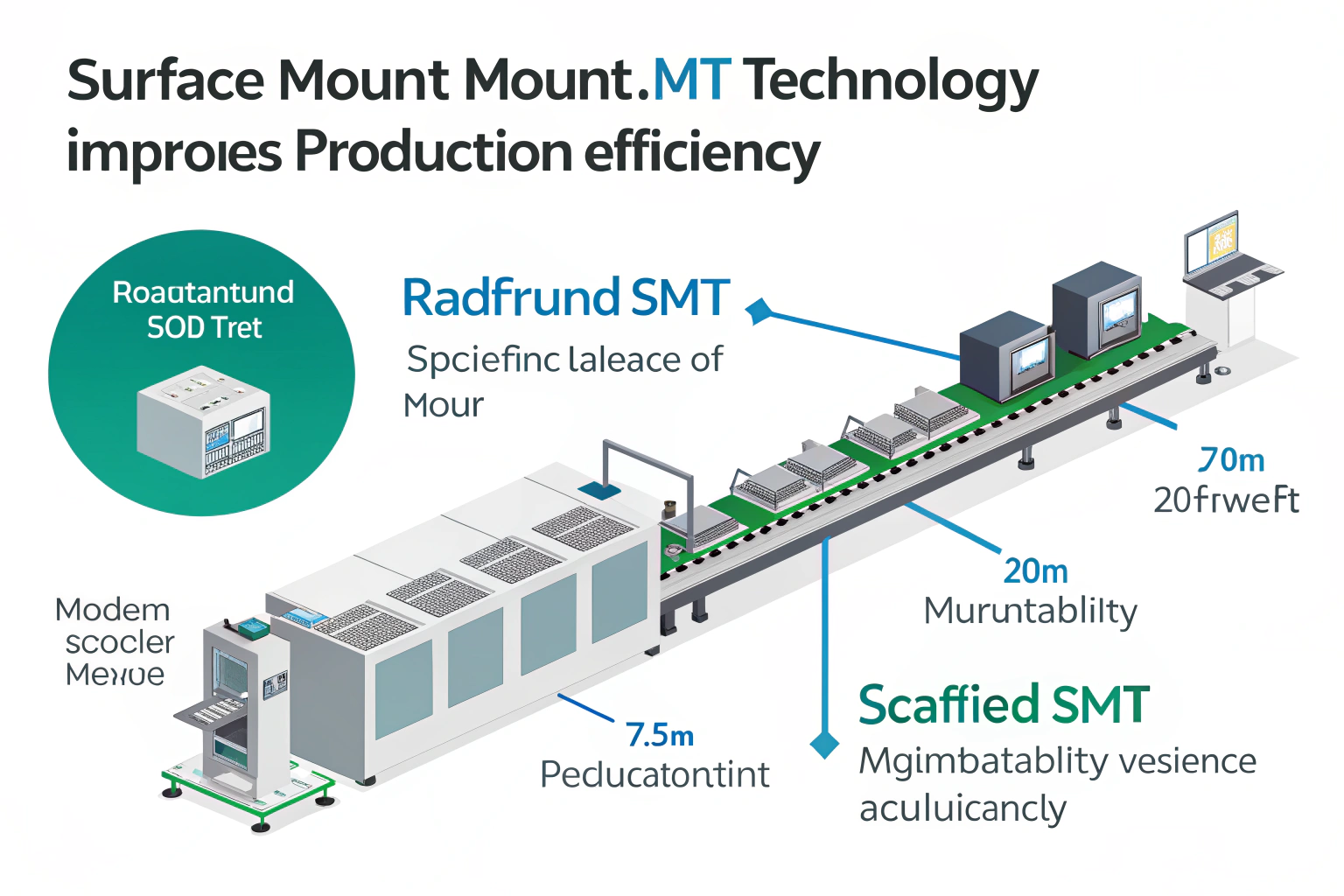

How does SMT improve production efficiency?

Speed and precision define modern manufacturing.

SMT lines can place thousands of components per hour, enabling rapid turnaround and scalable production.

Traditional through-hole soldering is labor-intensive and time-consuming. With SMT, automated lines handle solder paste printing, component placement, and reflow in continuous flow. Our Yamaha SMT machines operate at over 60,000 components per hour with ±0.03 mm accuracy. This efficiency allows customers to get prototypes within days and mass production within weeks. Shorter cycle time also reduces overall manufacturing cost without compromising quality.

| Equipment Type | Function | Placement Speed |

|---|---|---|

| Screen Printer | Applies solder paste | 8,000 PCB/hr |

| Pick & Place | Mounts components | 60,000 CPH |

| Reflow Oven | Soldering | 10 zones, 24°C–250°C |

How to overcome SMT challenges in production?

Smart control ensures stable quality.

Using advanced inspection tools, proper reflow profiling, and experienced engineers can eliminate most SMT process issues.

SMT success depends on precise control of solder paste, temperature, and component placement. Automated Optical Inspection (AOI) detects solder defects early, while X-ray inspection ensures BGA reliability. Our engineers continuously adjust reflow profiles to match component density and thermal sensitivity. When customers send new designs, we perform DFM analysis to catch layout risks before production. These actions ensure smooth assembly even for 0201 and fine-pitch QFN components.

| Control Step | Benefit |

|---|---|

| DFM Review | Prevent design-related defects |

| AOI + X-ray | Detect hidden solder issues |

| Reflow Profiling | Optimize temperature curve |

| Process Traceability | Ensure consistent quality |

SMT vs Through-Hole Technology – Which is better?

Both have roles in modern PCB assembly.

SMT is ideal for compact, automated designs, while Through-Hole is better for mechanical strength and high-power applications.

In consumer products like smartphones and wearables, SMT dominates due to space and cost efficiency. For large connectors, transformers, or mechanical switches, through-hole soldering remains valuable. Our factory often combines both methods—SMT for the main circuitry and THT for high-current or structural parts. This hybrid approach offers the best balance of performance, durability, and cost.

| Comparison | SMT | Through-Hole |

|---|---|---|

| Assembly Method | Automated | Manual/Semi-auto |

| Component Size | Small | Large |

| Strength | Medium | High |

| Density | High | Low |

| Typical Use | Consumer, IoT | Industrial, Power |

Conclusion

SMT has revolutionized electronic manufacturing with speed, precision, and miniaturization. Though it comes with setup costs and rework challenges, its advantages far outweigh its drawbacks. By combining skilled engineering with automated SMT lines, my factory ensures every PCB achieves high efficiency, consistent quality, and reliable performance for today’s fast-evolving products.