FR4 is one of the most commonly used materials in PCB fabrication due to its excellent balance of performance, durability, and cost-effectiveness. Whether you are designing simple consumer devices or advanced industrial systems, FR4 provides the foundation for reliable and high-performance circuit boards.

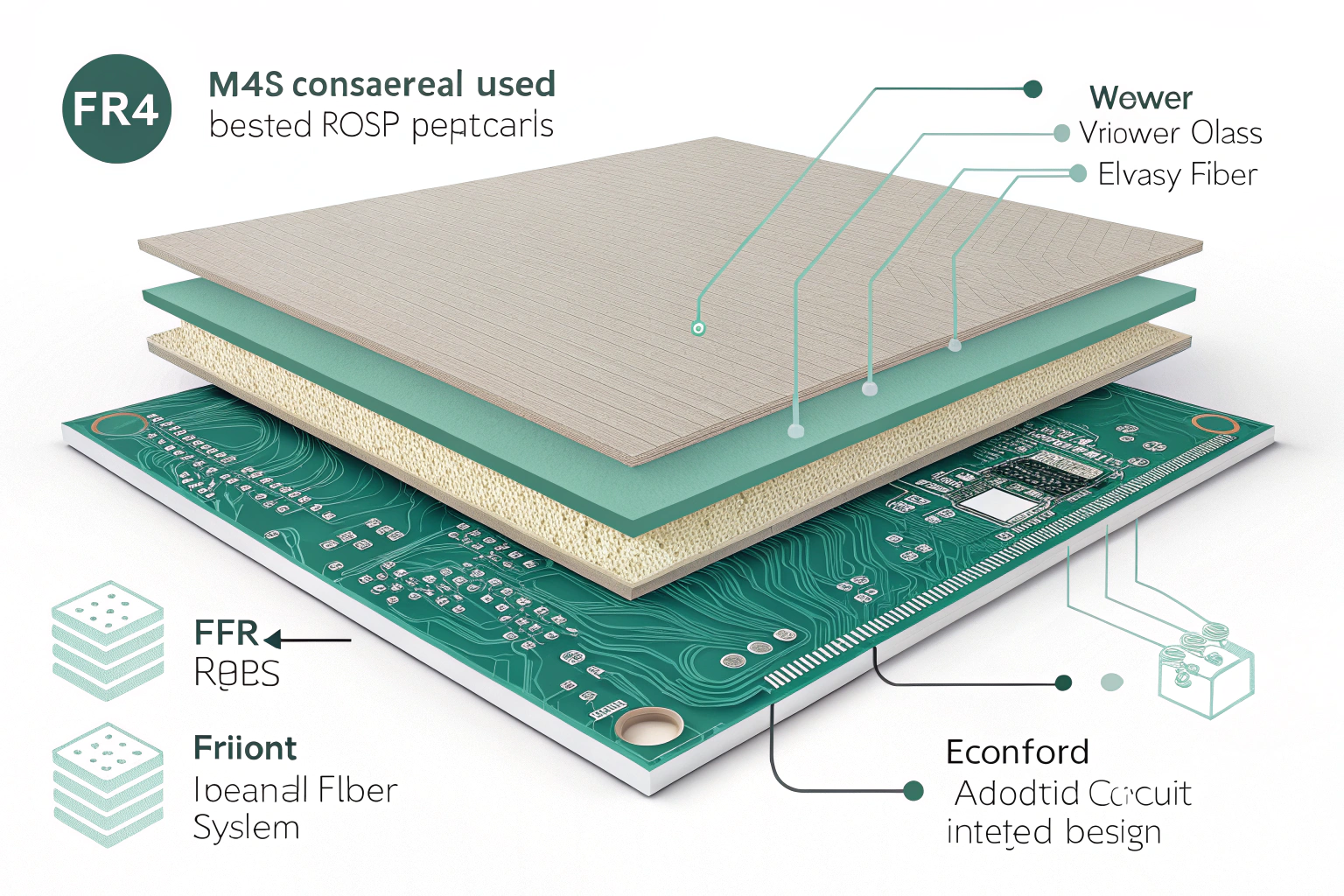

FR4 is a composite material made from woven glass fiber and epoxy resin, specifically designed to be used as a base for printed circuit boards (PCBs).

Understanding FR4 material and its role in PCB fabrication is essential for engineers and designers. In this article, we’ll discuss the properties, advantages, applications, and how FR4 compares to other PCB materials.

What is FR4 Material?

FR4 is a grade of fiberglass-reinforced epoxy laminate that is commonly used in PCB manufacturing.

FR4 is composed of an epoxy resin combined with glass fiber, giving it high mechanical strength, excellent electrical insulation properties, and good resistance to heat.

The "FR" in FR4 stands for “Flame Retardant,” indicating that it meets certain fire safety standards. FR4 is the standard material used for most PCB designs, providing a balance of durability and performance at a relatively low cost. It is used in both single-layer and multi-layer PCBs, making it ideal for a wide range of applications.

FR4 is highly reliable and versatile, offering electrical insulation and thermal resistance, making it suitable for everything from basic consumer electronics to more complex industrial systems.

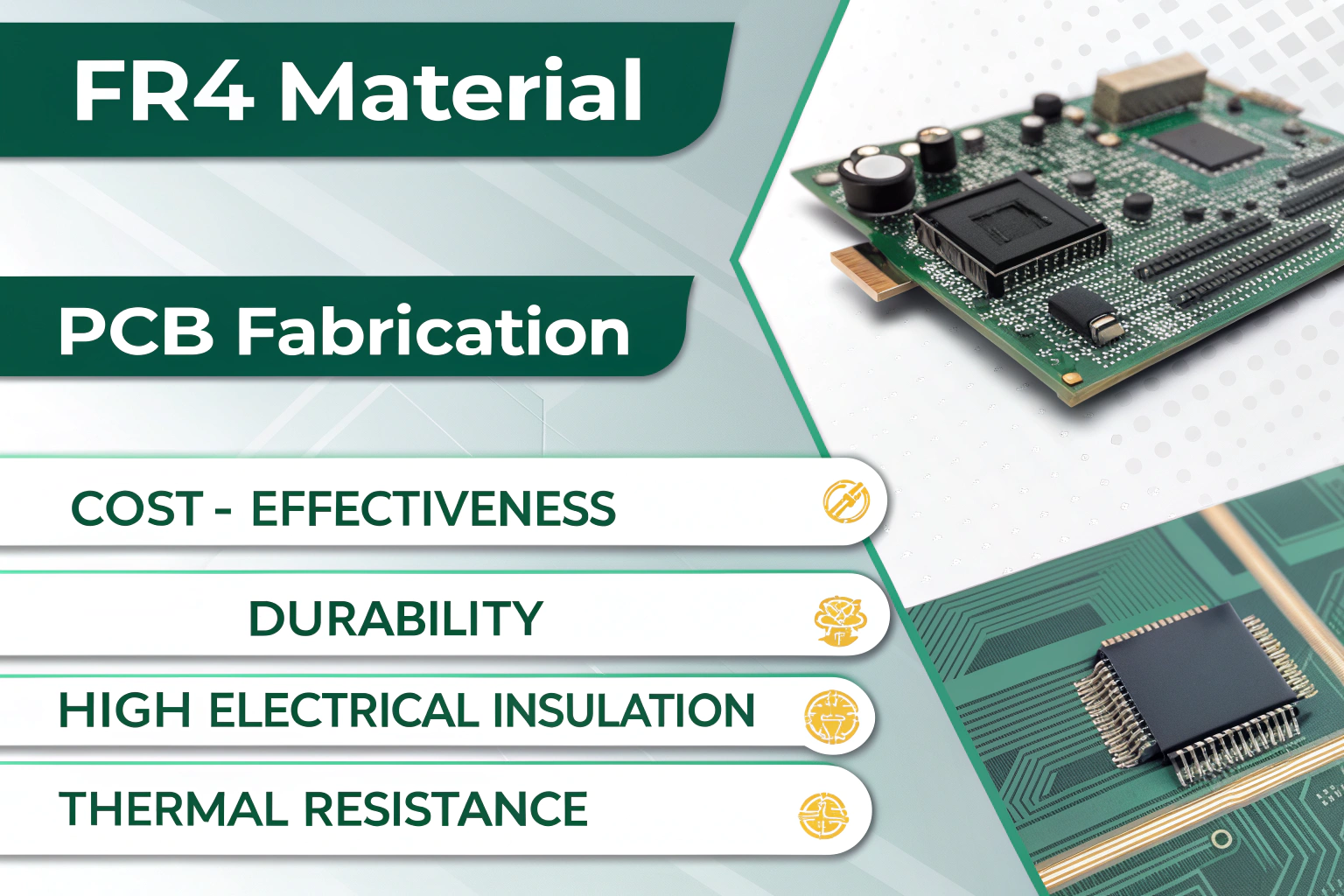

Advantages of FR4 for PCB Fabrication

The advantages of using FR4 for PCB fabrication include its cost-effectiveness, durability, high electrical insulation, and thermal resistance.

FR4 offers a robust platform for PCBs, ensuring that the circuit board remains functional even under demanding conditions. The material is capable of withstanding high temperatures, making it suitable for use in many electronics where heat dissipation is a concern. Additionally, FR4 provides excellent electrical insulation, which helps prevent short circuits and signal interference between traces.

However, the material also has limitations compared to specialized alternatives. For instance, while FR4 is versatile, it may not be suitable for applications requiring very high-frequency signals or extreme thermal conditions, where materials like Rogers or polyimide might be preferred.

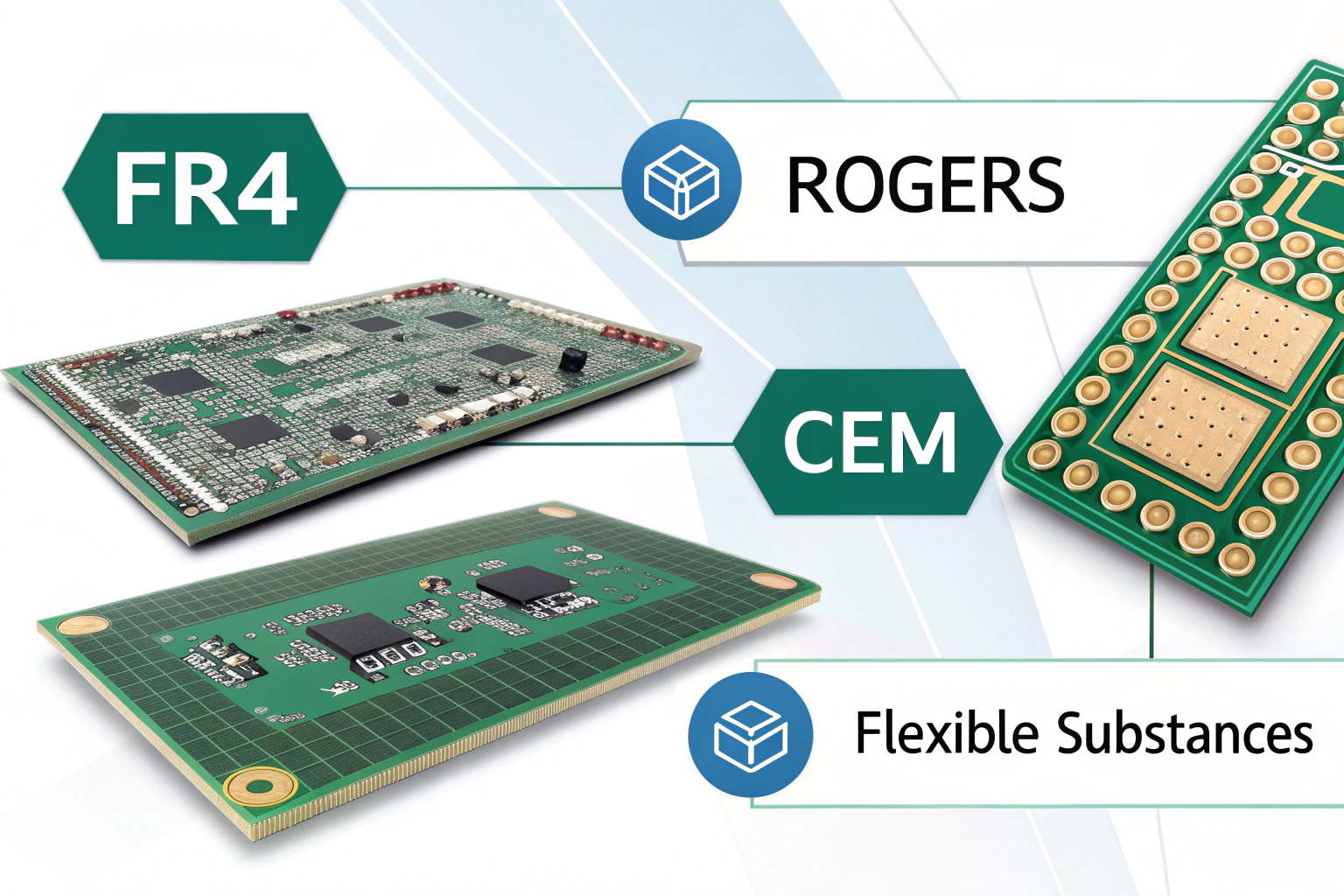

Comparing FR4 with Other PCB Materials

While FR4 is the standard PCB material, there are other materials used for specialized applications where FR4 may not perform optimally.

Compared to other PCB materials like Rogers, CEM, and flexible substrates, FR4 offers a more affordable and versatile solution for most applications.

Materials like Rogers are often used for high-frequency applications due to their superior dielectric properties, while flexible PCBs made from materials like polyimide are used in flexible and foldable electronics. However, FR4 remains the most widely used material because of its balance of performance, availability, and cost-effectiveness.

| Material | Characteristics | Use Cases |

|---|---|---|

| FR4 | Durable, cost-effective, flame retardant | Consumer electronics, automotive, general-purpose |

| Rogers | High-frequency, low loss, stable dielectric | RF and microwave applications |

| CEM | Low cost, lower mechanical strength | Budget-friendly consumer electronics |

| Polyimide (Flexible) | Flexible, heat resistant, thin | Wearable devices, flexible circuits |

Each material has specific strengths that make it suitable for certain applications, but for most general-purpose PCB designs, FR4 remains the material of choice due to its overall reliability and versatility.

Conclusion

FR4 is the backbone of modern PCB fabrication, providing a reliable, cost-effective, and versatile material for a wide range of applications. From consumer electronics to industrial systems, FR4 offers excellent electrical insulation, thermal resistance, and mechanical strength. While specialized applications may require alternative materials, FR4 remains the most widely used and trusted material in the PCB industry. In our factory, we ensure that every FR4 PCB meets the highest standards of quality and performance, delivering durable and reliable products for our customers’ needs.