One-stop SMT PCBA Assembly Service – Fast Delivery in 48 Hours with Guaranteed Quality!

Get your prototypes or small-batch PCBA orders assembled and shipped within 48 hours. We ensure high-speed delivery without compromising on quality or reliability.

Support for diverse PCB layouts, components, and special assembly requirements.

Strict QC with AOI, X-ray, and functional testing for every assembled board.

Factory-direct supply with flexible MOQ and optimized production cost.

One-Stop SMT PCBA Services You Can Trust.

From prototype to mass production, we provide complete SMT assembly, components sourcing, and PCBA testing – all under one roof. Enjoy fast response, global shipping, and professional engineering support.

Trusted by global clients across electronics, IoT, medical, and industrial fields.

Global shipping available with multilingual support and export compliance.

PCB Assembly Solutions

Explore our wide range of high-quality PCB assemblies, tailored to meet diverse industry needs. Fast lead times, reliable performance, and fully customized to your specifications.

From Prototype to Production

End-to-End SMT PCBA Services for Global Electronics Projects

- High-quality SMT assembly with 0402, BGA, QFN precision — backed by AOI & X-ray.

- Full PCBA support: PCB fabrication, components sourcing, assembly, testing.

- ISO-certified factory with 20+ years of manufacturing experience.

- Worldwide shipping + one-on-one technical support for fast project delivery.

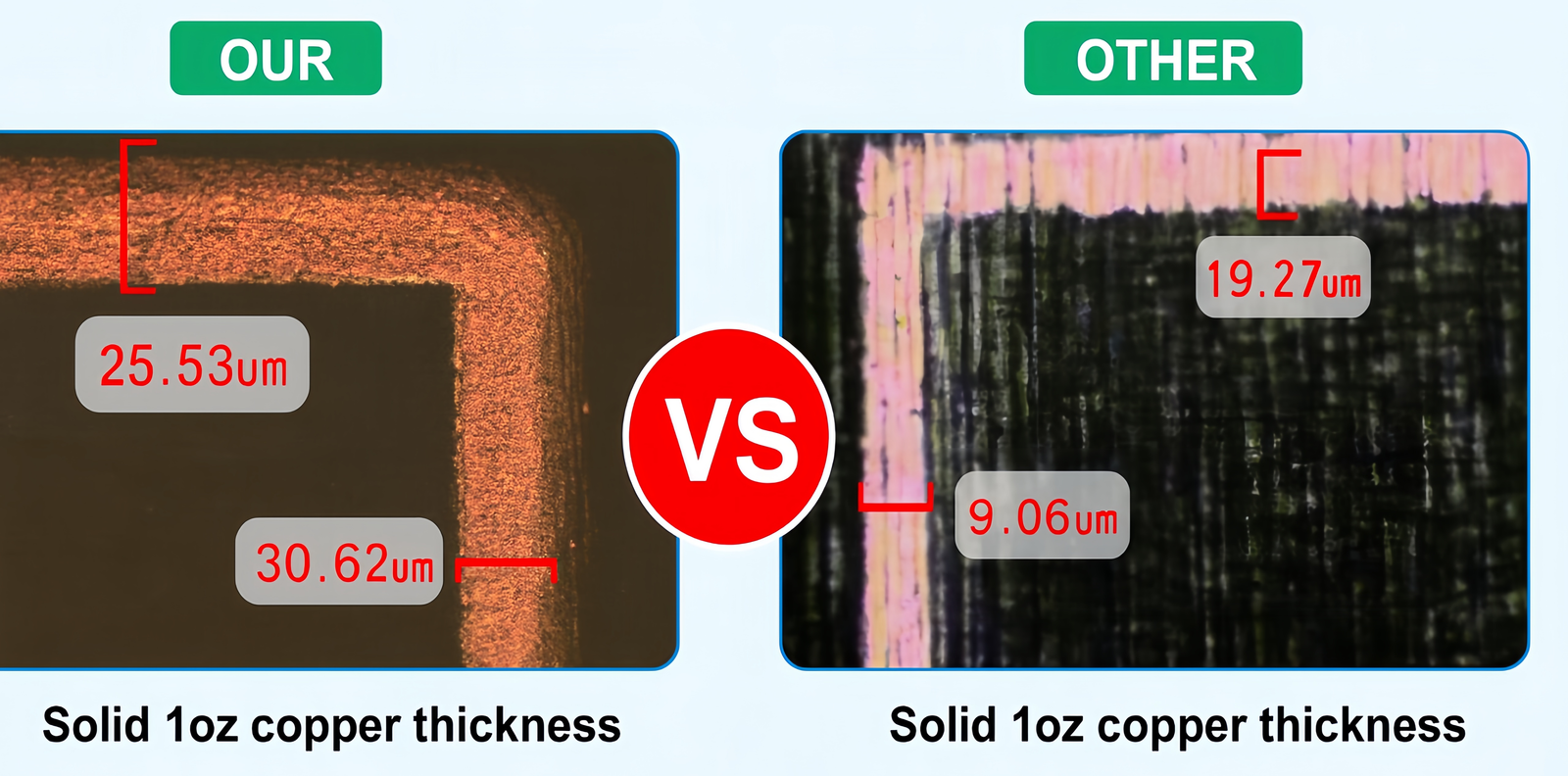

True 1oz Copper Thickness for Reliable Performance

We deliver what we promise—our PCBs feature genuine 1oz copper thickness, with measurements exceeding 25μm and even reaching over 30μm in critical areas. This ensures excellent current-carrying capacity, thermal management, and long-term durability in demanding applications.Thicker Copper, Stronger Boards

Compared to others that offer inconsistent and under-spec copper layers, our PCBs maintain solid, uniform copper thickness throughout the board. This provides better mechanical strength, reduced risk of circuit failure, and enhanced reliability for high-performance electronics.Precision Plating with Guaranteed Quality

Every copper layer on our PCBs is precisely controlled using advanced plating technology. With consistent inner and outer layer thickness, we minimize resistance and improve signal integrity—ensuring your product performs flawlessly, even under stress.Engineered for High-Power Applications

Whether it’s for power electronics, automotive systems, or industrial control, our true 1oz copper PCBs are built to withstand high current and heat. Don’t compromise with thin copper—choose a board that’s engineered for strength, stability, and reliability.

Focused on High-Quality SMT and PCBA Assembly

PCB Prototyping & Mass Production

SMT Assembly Services

Electronic Components Sourcing

PCBA Functional Testing & Aging

Through-Hole Soldering & Final Assembly

One-on-One Engineering Support

WHY CHOOSE US

More Efficient, Reliable, and Supportive Than Traditional PCBA Suppliers

We combine fast response, rigorous quality control, and hands-on engineering support to help you reduce cost, speed up production, and ensure reliable delivery — all in one place.

Once your project details are submitted, our engineering team evaluates and returns a precise quote within just 1 hour — helping you move fast and stay ahead.

Standard prototypes delivered in 3 days, with expedited options as fast as 48 hours. In-house production ensures flexible scheduling and stable lead times.

We go beyond sampling — every PCBA board undergoes both automatic optical inspection and X-Ray solder testing to ensure top-level quality and reliability.

Your project will be followed up by a dedicated engineer from start to finish, providing DFM advice, technical solutions, and quick responses to every question.

End-to-End Delivery Management System to Ensure Every Order Is On Time

Real-time tracking, production scheduling, and delivery guarantees — all in one integrated system built for on-time fulfillment.

In the electronics manufacturing industry, delivery time is everything. We understand that every delay could mean a postponed product launch, a lost customer, or even the failure of an entire project. That’s why we’ve built a fully visualized production scheduling system, powered by real-time MES tracking, to ensure every order progresses smoothly and stays on schedule. For urgent projects, we offer expedited production with delivery in as fast as 48 hours—giving hardware teams valuable time back.

Speed is important—but reliability matters more. We offer a Delivery Guarantee Agreement that defines all key milestone deadlines. If any delay is caused by us, clients are entitled to compensation. Our engineering and customer service teams work seamlessly together to provide timely support, while our compensation mechanism remains clear and transparent. We don’t just promise—we deliver on time, every time, with full accountability.

Talk to our engineers and get expert PCBA support — faster, smarter, and fully integrated.

From prototype to mass production, we provide end-to-end SMT assembly and PCBA solutions tailored to your design, timeline, and quality standards. Whether you’re building a startup MVP, upgrading an existing product, or scaling for volume — our team is ready to support you every step of the way.

Advanced Equipment, Precision Manufacturing

Equipped with precision machines for drilling, printing, exposure, and more, our facility ensures stable production and consistent PCB quality at every step.

Flexible Support for Every Stage — From Prototyping to Mass Production

From low-volume samples to high-volume orders, we adapt to your needs with scalable production, custom testing, and industry-specific expertise.

Whether you’re developing a prototype, preparing a small production run, or scaling to mass production, our flexible PCBA solutions adapt to your needs. We support quick-turn prototyping from just 1 unit and handle high-volume orders exceeding 500,000 placements — all with the same trusted team and facility.

We go beyond assembly with services like custom test jig development, firmware programming, and tailored inspection processes. Our engineers work closely with your team to reduce failure rates, improve consistency, and accelerate time-to-market.

With experience in medical, industrial, and automotive electronics, we understand the standards and certifications these sectors demand. From anti-static handling to vibration-resistant design, we offer process control and technical support for real-world applications.

Who have we worked with?

We partner with leading global brands across industries such as electronics, automotive, and medical devices. Our expertise in PCBA manufacturing ensures high-quality, reliable products that meet the most demanding standards. Through these collaborations, we help our clients achieve superior performance and innovation in their markets.

Our Certificates Showroom

Our Certifictaes can meet all different requirements from all industries and countries. Welcome to contact us for your projects.

We would love to hear from you

It starts here

With over 40 years experience in the industry. We know a thing or two about PCB manufacturing.

If you can’t find what you are looking for, please don’t hesitate to get in touch directly.

Simply fill in the form and we will try to get back to you ASAP. Alternatively, you can call or email us on the details below.

long@custompcba.com

+86 18123721954