Surface Mount Technology (SMT) is the most widely used method in the modern electronics manufacturing industry. It revolutionized how electronic circuits are assembled, allowing for more compact designs and faster production.

SMT stands for Surface Mount Technology, a method used to mount electronic components directly onto the surface of a PCB, rather than through holes.

Understanding SMT is crucial for engineers and manufacturers, as it plays a vital role in ensuring efficiency, miniaturization, and high-quality performance in a wide range of electronic devices. In this guide, we’ll take a deep dive into the SMT process, its features, and its applications across various industries.

What is SMT (Surface Mount Technology)?

SMT involves mounting components directly onto the surface of a PCB instead of inserting leads through holes.

In traditional through-hole technology (THT), components have leads that pass through holes in the PCB, making it a more labor-intensive process. SMT, on the other hand, places components like resistors, capacitors, and ICs directly onto the PCB’s surface, with soldering done using paste and reflow techniques. The process allows for greater precision, smaller components, and faster production times, making it the go-to method for high-volume manufacturing.

| SMT vs THT | SMT | THT |

|---|---|---|

| Mounting Method | Components placed on the surface | Components inserted through holes |

| Components | Smaller, compact | Larger, bulkier |

| Assembly Time | Faster | Slower |

| Application | High-density, miniaturized designs | Larger components or high-power applications |

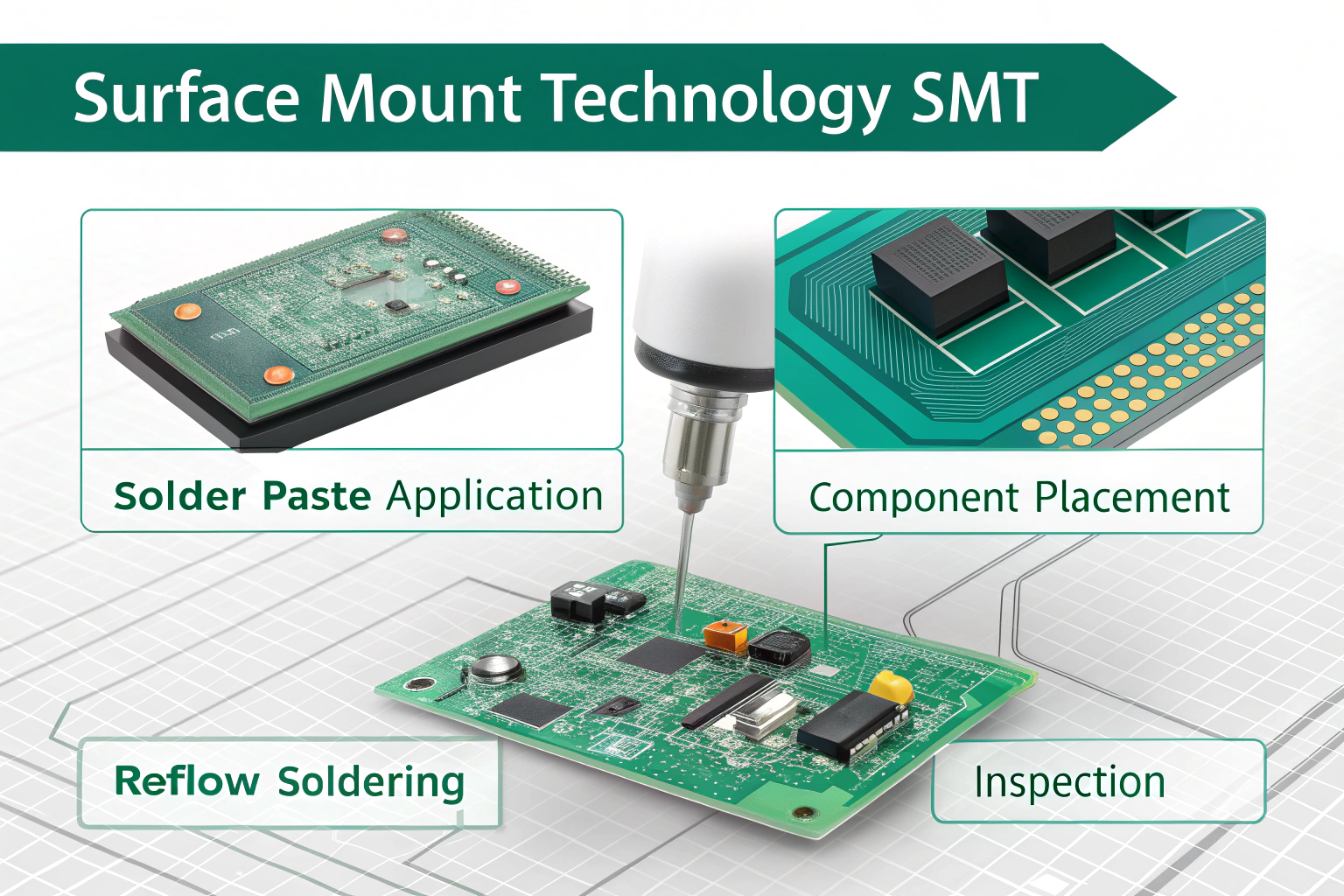

The SMT Process: How Does It Work?

SMT involves several steps to ensure components are properly mounted and soldered.

The typical SMT process includes solder paste application, component placement, reflow soldering, and inspection.

-

Solder Paste Printing: First, solder paste is applied to the PCB pads using a stencil printer. The paste is made of tiny solder balls mixed with flux and is essential for creating the solder joints that will connect the components to the PCB.

-

Pick-and-Place: In this step, automated machines pick up components and place them on the PCB pads with high precision. The placement accuracy is crucial for small components like 0201s and BGAs.

-

Reflow Soldering: After the components are placed, the PCB goes through a reflow oven where the solder paste is heated and melted to form permanent solder joints.

-

Inspection: The soldering quality is checked using Automatic Optical Inspection (AOI) or X-ray inspection for more complex components like BGAs.

These steps make the SMT process highly efficient and reliable for assembling even the most complex and miniaturized PCBs.

Features of SMT: Why is it Popular?

SMT offers several benefits that have made it the industry standard in electronics manufacturing.

The main features of SMT include smaller component sizes, faster production speeds, better electrical performance, and the ability to integrate more components on a single board.

Some of the key advantages of SMT are:

- Compact Design: Components mounted directly on the surface allow for more compact circuit designs.

- High-Speed Assembly: Automated SMT lines can handle thousands of components per hour, dramatically reducing manufacturing time.

- Better Electrical Performance: Shorter traces and connections reduce signal loss and electromagnetic interference.

- Cost-Effective for High-Volume: The automation and efficiency of SMT make it cost-effective, particularly in high-volume production.

These advantages make SMT the preferred method for many industries, especially those focusing on miniaturization and efficiency.

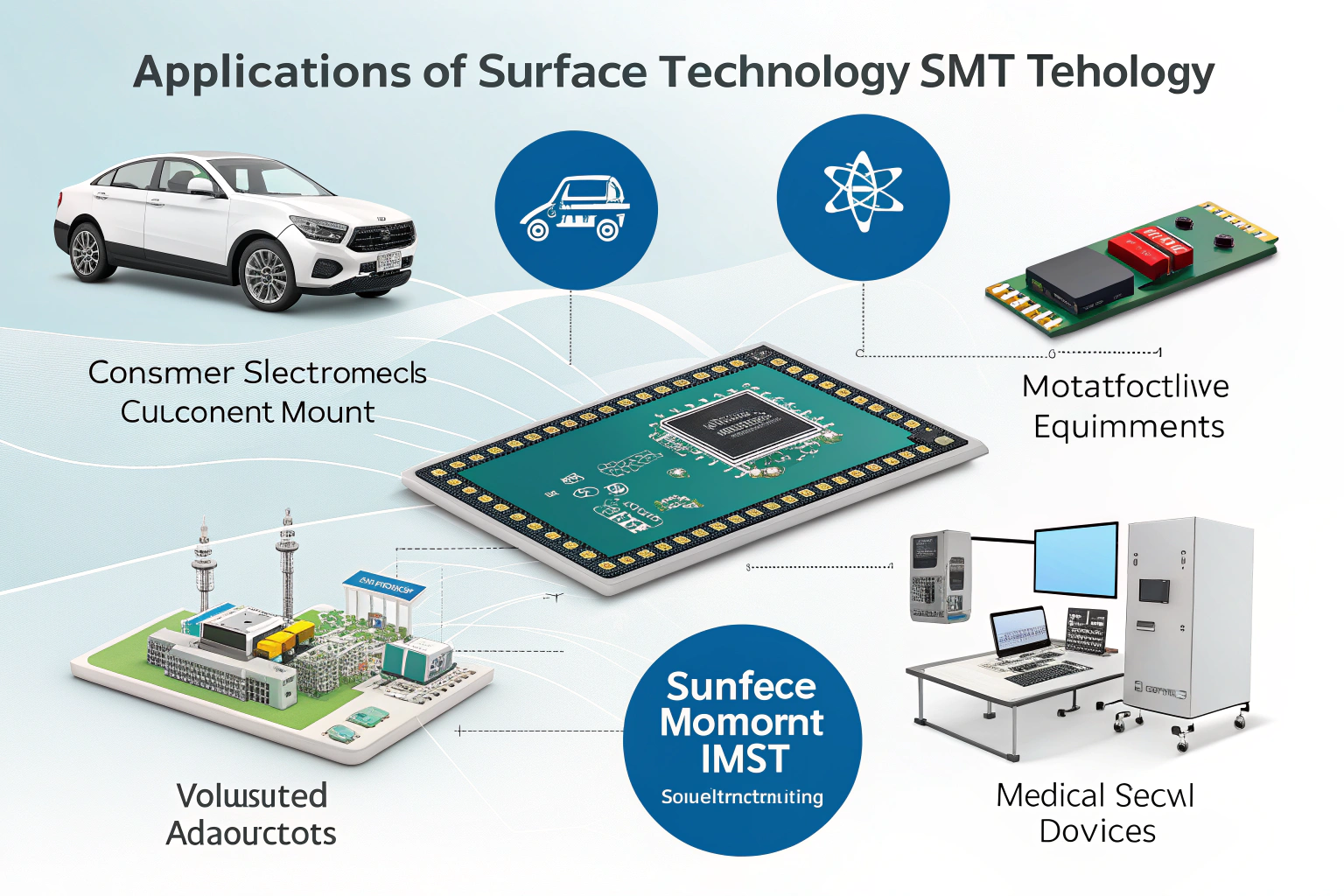

Applications of SMT in Electronics

SMT is used in a variety of electronic devices and industries due to its advantages in size, speed, and performance.

SMT is commonly used in consumer electronics, telecommunications, automotive, and medical devices.

Some of the most common applications of SMT include:

- Consumer Electronics: Smartphones, tablets, and wearable devices use SMT for their compact design and high-density components.

- Automotive: SMT is widely used in automotive electronics for things like sensors, control units, and infotainment systems.

- Medical Devices: In medical equipment, SMT helps with miniaturization and reliability, especially in devices like hearing aids and diagnostic equipment.

- Telecommunications: SMT plays a crucial role in the production of routers, network switches, and wireless devices, where small form factors and efficient designs are critical.

| Industry | SMT Application |

|---|---|

| Consumer Electronics | Smartphones, wearables, gaming consoles |

| Automotive | Control systems, sensors, infotainment |

| Medical Devices | Hearing aids, diagnostic equipment |

| Telecommunications | Routers, network infrastructure |

By enabling smaller, lighter, and more powerful devices, SMT is transforming how electronic products are designed and manufactured.

#

Conclusion

SMT is a transformative technology that has greatly improved the efficiency, performance, and miniaturization of electronic devices. From smartphones to automotive systems, SMT enables the production of highly integrated and compact circuit boards. Understanding the SMT process, its features, and its wide range of applications is essential for anyone involved in the design or manufacturing of electronic products. In our factory, we utilize advanced SMT techniques to ensure that our customers receive the highest quality, cost-effective PCBs for their applications.