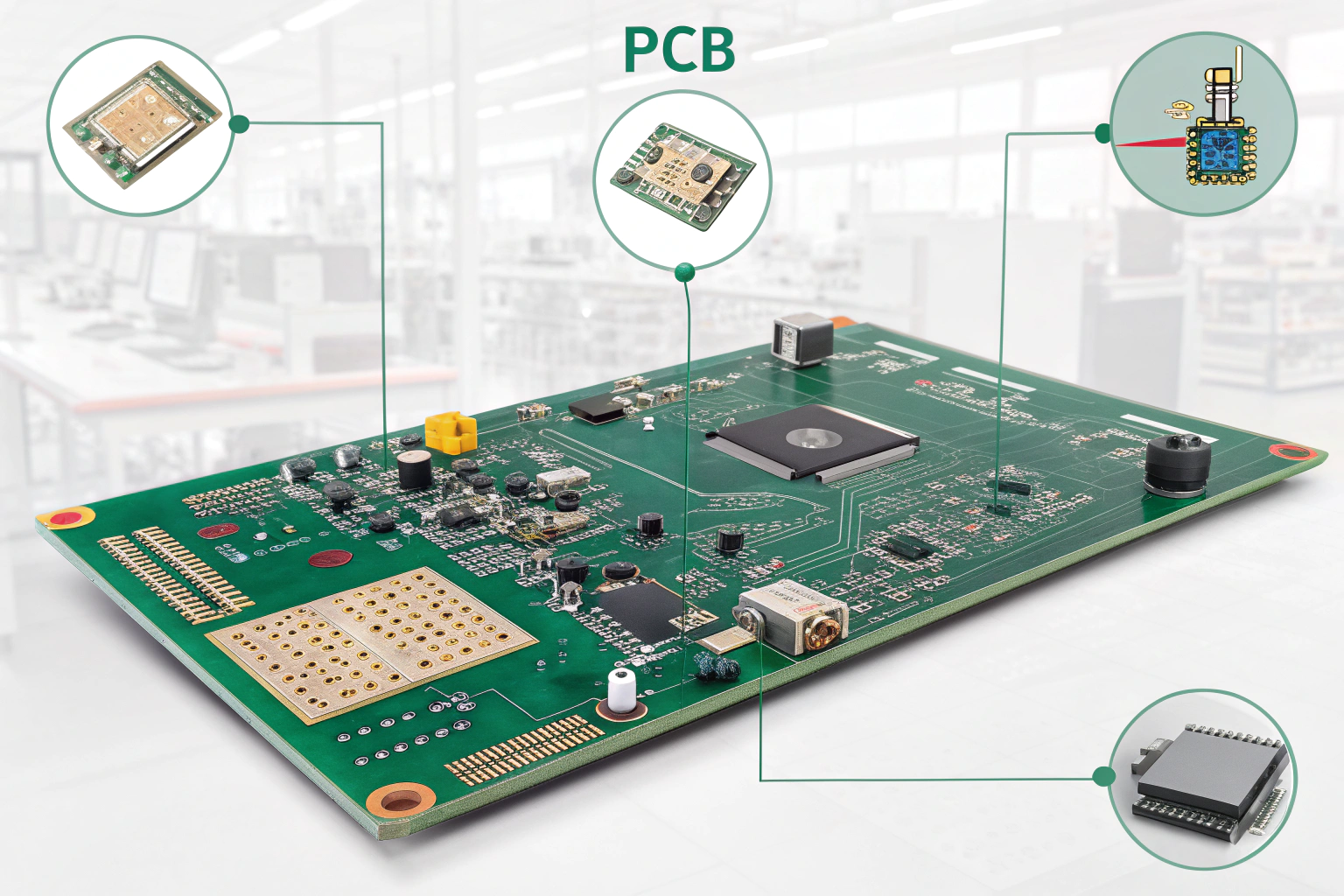

A faulty Printed Circuit Board (PCB) is a board that fails to meet electrical, functional, or reliability requirements at any stage of its lifecycle. This failure may occur during assembly, testing, or operation. In manufacturing environments, a faulty PCB is not only a defective product but also a signal that design, materials, processes, or controls require attention.

A PCB can appear visually acceptable and still be classified as faulty. Many defects are hidden within solder joints, inner layers, or electrical behavior under load. For this reason, professional manufacturing operations rely on structured inspection, testing, and process monitoring to define and manage PCB faults accurately.

How Is a Faulty PCB Defined in Manufacturing?

In manufacturing terms, a faulty PCB is any board that does not conform to defined specifications, drawings, or performance criteria.

A PCB is considered faulty when it:

- Fails electrical or functional testing

- Shows abnormal behavior under specified conditions

- Does not meet assembly or workmanship standards

- Exhibits instability, intermittence, or early failure

Manufacturing quality systems define acceptance criteria based on industry standards, internal process rules, and product requirements. A board that violates any of these criteria is classified as faulty, even if it partially works.

This definition ensures that quality control focuses on long-term reliability rather than short-term functionality.

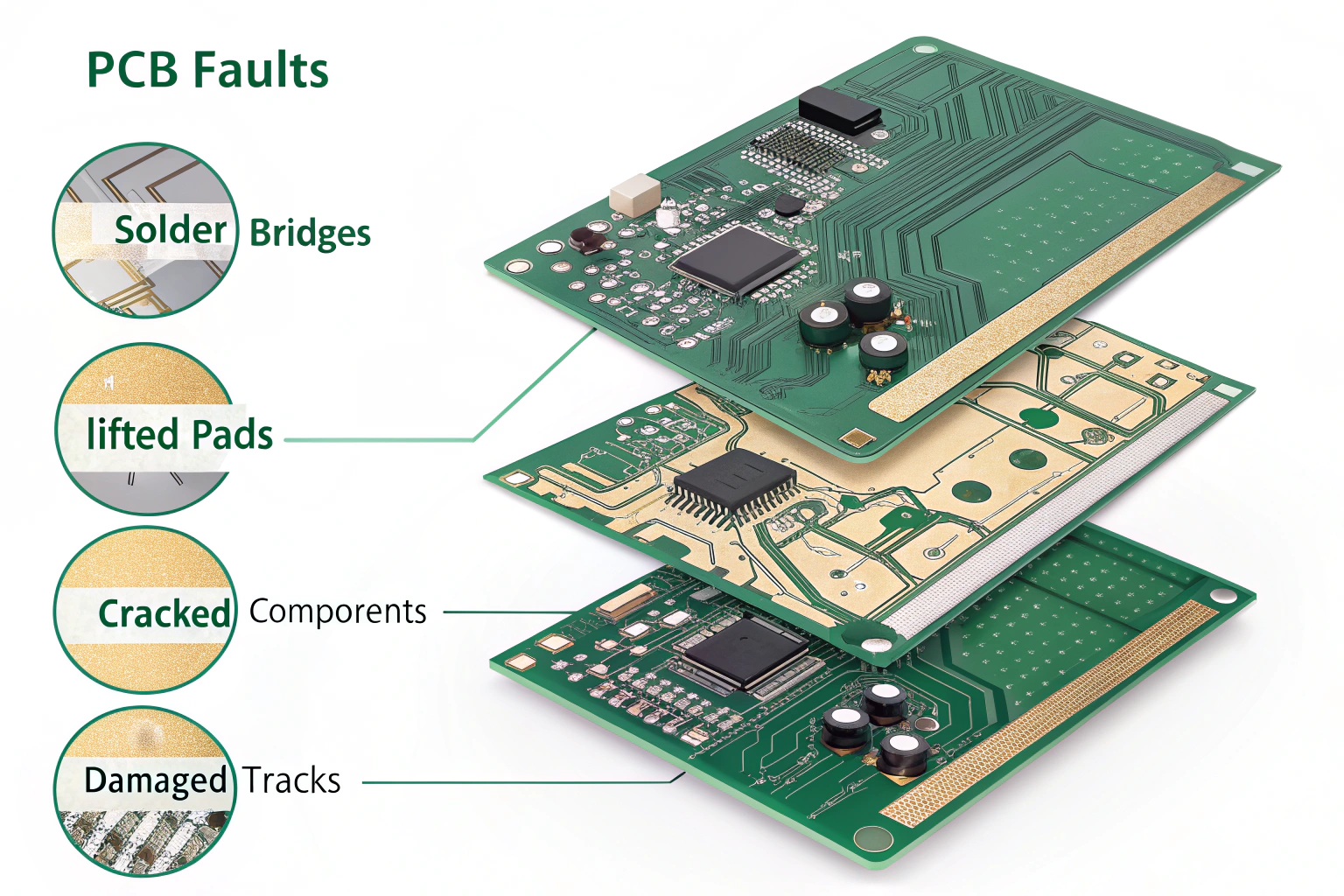

What Are the Common Types of Faulty PCBs?

Faulty PCBs can be grouped into several categories based on the nature of the defect.

Common fault types include:

- Assembly-related faults such as solder bridges or cold joints

- Component faults including wrong parts or damaged devices

- Electrical faults such as shorts, opens, or incorrect impedance

- Functional faults related to timing, communication, or logic

- Reliability faults caused by weak solder joints or material stress

In factory workshops, these faults are detected at different stages of production. Assembly faults are often found through AOI, while electrical and functional faults are revealed during ICT or functional testing. Reliability-related faults may only appear during burn-in or stress testing.

Understanding fault categories helps manufacturing teams assign the correct testing and corrective actions.

What Causes a PCB to Become Faulty?

A PCB becomes faulty due to a combination of design, material, and process factors rather than a single isolated issue.

Typical root causes include:

- Incomplete design-for-manufacturing or testing

- Poor solder paste printing or reflow control

- Inaccurate component placement

- Material quality or storage issues

- Inadequate testing coverage

In manufacturing environments, faults are often traced back to process deviations rather than operator mistakes. For example, unstable reflow profiles may cause widespread solder defects, while insufficient test access can allow hidden faults to pass undetected.

Root cause analysis is essential. Treating symptoms without addressing the underlying cause increases the risk of repeated failures.

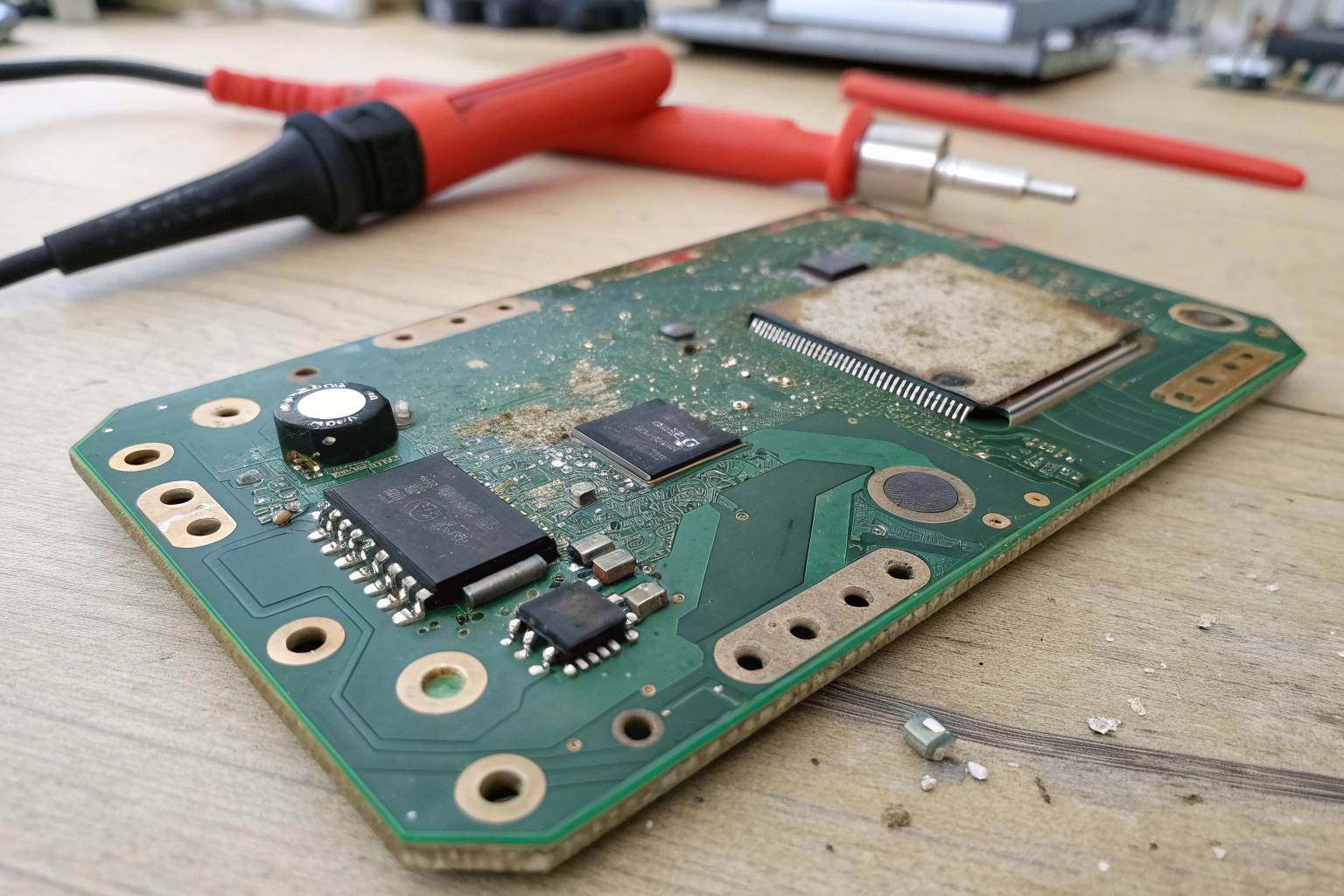

How Are Faulty PCBs Detected in Factory Workshops?

Detecting faulty PCBs requires a layered testing strategy integrated into the production line.

Common detection methods include:

- Visual inspection and Automated Optical Inspection

- Electrical continuity and isolation testing

- In-Circuit Testing for component-level verification

- Functional Circuit Testing under real conditions

In professional workshops, testing stations are positioned to catch defects as early as possible. Early detection reduces rework cost and prevents faulty boards from progressing to later stages.

Test data is collected and analyzed to identify trends. Repeated failures at the same points often indicate systemic issues in design or process control.

How Do Manufacturing Processes Influence PCB Fault Rates?

Manufacturing processes play a decisive role in determining whether a PCB becomes faulty.

Key process influences include:

- SMT placement accuracy and stability

- Solder paste quality and stencil design

- Reflow temperature profile consistency

- ESD protection and handling discipline

Well-controlled workshops use standardized work instructions, regular equipment calibration, and real-time monitoring. Process deviations are detected quickly and corrected before they affect large production volumes.

Facilities with integrated assembly, testing, and engineering support can respond faster to faults, reducing defect rates and improving overall yield.

Why Is a Faulty PCB a Serious Quality Concern?

A faulty PCB affects more than a single unit. It represents potential risks to product performance, reliability, and lifecycle cost.

Consequences of faulty PCBs include:

- Increased rework and scrap rates

- Delayed production schedules

- Reduced product lifespan

- Higher field failure risk

Manufacturing quality systems treat faulty PCBs as learning opportunities. Failure data feeds back into design reviews, material selection, and process optimization. This closed-loop approach transforms defects into drivers for continuous improvement.

Conclusion

A faulty PCB is a board that fails to meet defined electrical, functional, or reliability standards, regardless of its visual appearance. In manufacturing environments, faulty PCBs are viewed as indicators of deeper design or process weaknesses rather than isolated problems. Through structured inspection, comprehensive testing, disciplined workshop processes, and continuous data analysis, fault rates can be reduced and long-term product stability improved. A mature manufacturing system does not simply identify faulty PCBs but uses every fault as a foundation for stronger quality control and more reliable electronic products.