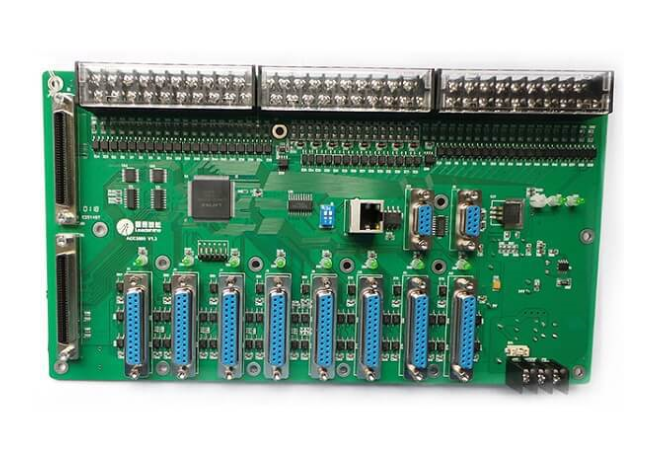

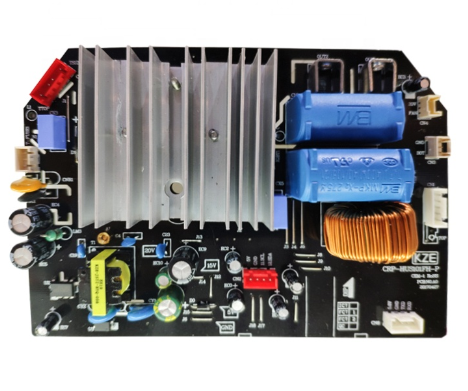

High-end manufacturing service provider for fast SMT small and medium batch production, industrial control industry, smart home, communication medical PCBA

We design PCBA solutions based on your exact functional needs, ensuring full alignment with product performance, structure, and application scenarios.

We offer dedicated one-on-one PCBA solution development tailored to your product’s positioning and functional needs. From circuit design, MCU selection, signal interface, and power management to RF layout, we ensure every aspect aligns with your technical goals—whether in consumer, medical, or industrial applications.

Unlike generic modules, our service begins with a deep understanding of your concept and challenges. We turn your ideas into reliable, production-ready circuits with optimized layout and stable performance. From prototype to mass production, we help speed up time-to-market without compromising quality.

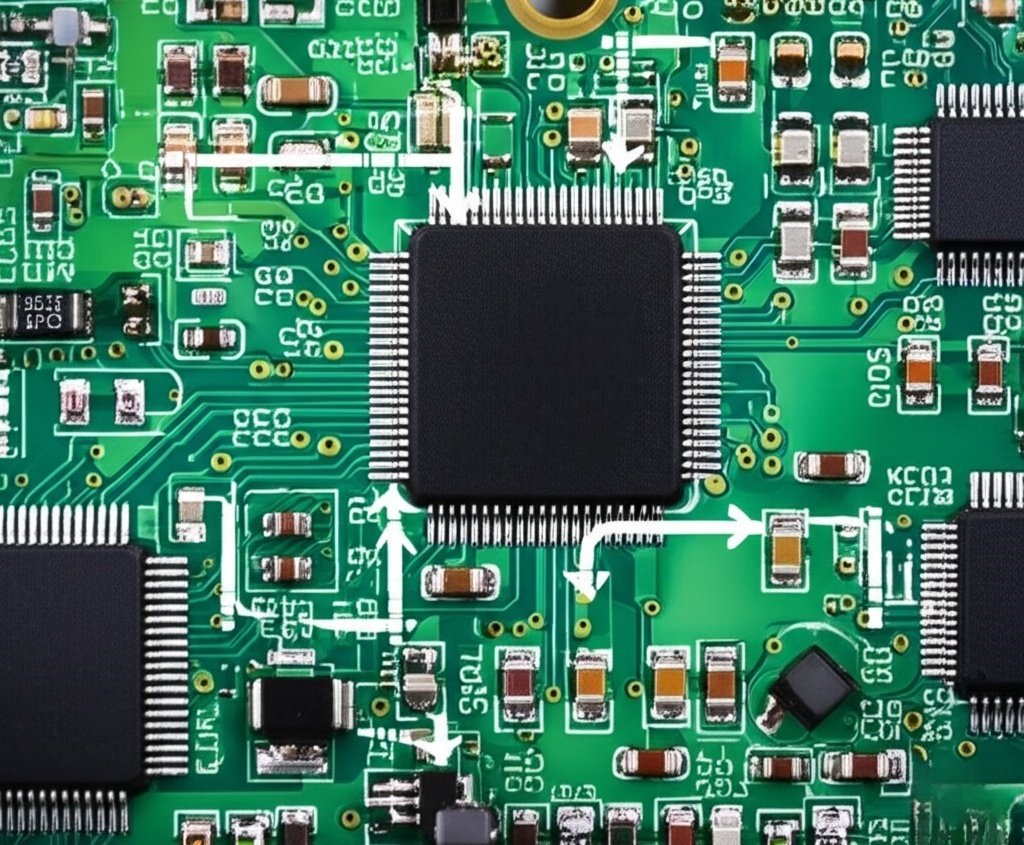

We specialize in integrating a wide range of components into complex PCBA designs. Through strong partnerships with top-tier semiconductor brands and authorized distributors, we’re highly familiar with various ICs, drivers, sensors, and power modules. Our team excels at BOM integration, signal coordination, and component compatibility, ensuring stable, high-performance boards in tight-space and multi-module applications.

From limited board space to complex functional zones and communication interfaces, we offer optimized PCB layouts and advanced EMI mitigation strategies. We address signal conflicts, interference, and inconsistent pin mapping early—delivering clean signal paths and a reliable electrical foundation.

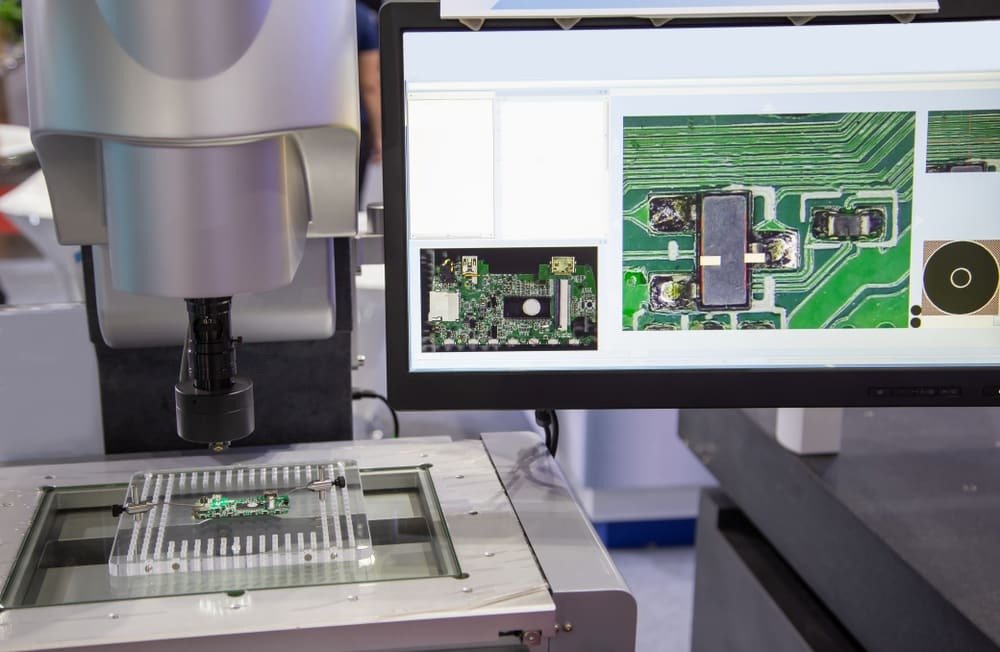

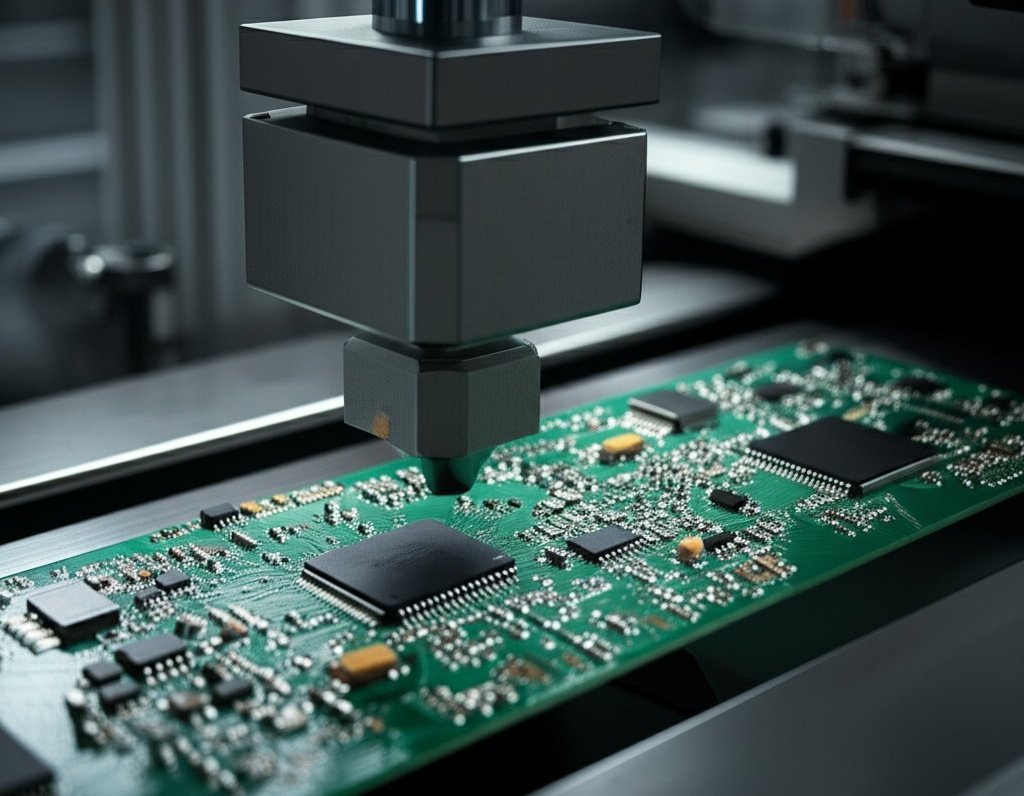

Our fully automated SMT line includes 9 inspection processes to ensure the highest quality for you.

Our fully automated SMT line includes 9 inspection processes to ensure the highest quality for you.

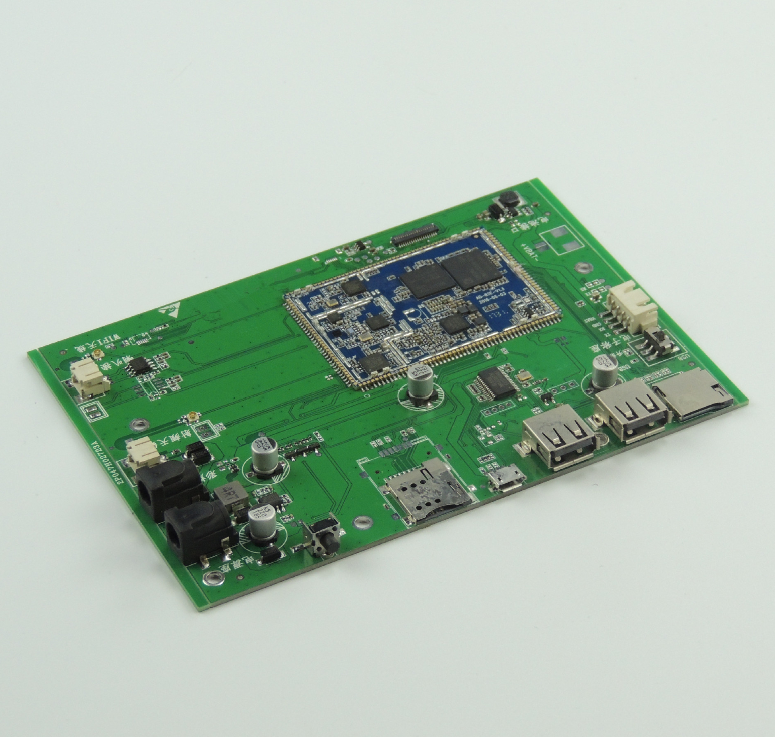

For urgent validation of functional boards or complete control units, we offer fast-turnaround prototyping services. We support small-batch production with delivery in as little as 3 days. All assembly and soldering are completed using fully automated equipment, ensuring that every prototype meets production-level quality and can proceed directly to testing and validation.

When speed matters, we deliver. Our rapid PCBA prototyping service supports fast functional testing and early-stage validation. Whether it’s a complex control board or compact module, we can deliver small-batch samples in as fast as 3 working days.

With fully automated SMT lines, reflow soldering, and AOI inspection, every prototype meets production-grade standards. High-speed, precision placement minimizes defects like misalignment or cold joints, ensuring reliable, test-ready samples.

Rapid prototypes help your team identify issues early, iterate faster, and accelerate time-to-market. From Gerber confirmation to final QC, our streamlined workflow ensures fast, consistent, and high-quality delivery.

Our fully automated SMT line includes 9 inspection processes to ensure the highest quality for you.

Surface Mount PCB Assembly(SMT)

Through Hole PCB Assembly

Flex PCB Assembly

PCBA Components Assembly(SMD or Thru-hole)

Single or Double Sided PCB Assembly

Finished PCB Assembly

Quick Turn(same day consigned)

Fast PCB Assembly(2-5 days)

High Volume(10 days)

Scheduled Delivery

No MOQ

Prototype PCB Assembly

Excellent Services for Small,Medium,and Large Batch Products

Leaded

Lead-free/RoHs Compliant

No-clean and Water Clean Fluxes

Passive Components(01005, 0201, 0402, 0603)

ICs (BGA, QFN, QFP, Pitch of 0.2 mm, PLCC, SOIC, POP)

Small Pitch of 8 Mils

Prototyping

Conformal Coating

Box Build

DFM Analysis

XRAY Inspection

Reverse Engineering

Yes. We offer full-cycle PCBA solution development starting from product concept or functional goals. Our team supports circuit design, component selection, firmware integration, layout, prototyping, and mass production preparation.

For standard projects, we can deliver prototypes within 3–5 working days. For urgent or fast-track cases, we offer 3-day rapid prototyping. The exact timeline depends on BOM complexity and PCB specifications.

Yes. We support both full turnkey services (including component sourcing) and consigned assembly where you provide part or all of the components. We’re flexible based on your project needs.

Our engineering team has extensive experience in component integration. We carefully evaluate compatibility at the schematic, layout, and electrical levels, and recommend alternative components if needed to ensure supply stability and signal integrity.

We provide PCBA solutions for a wide range of industries, including consumer electronics, medical devices, industrial automation, smart home, IoT, and automotive electronics. Each solution is developed in compliance with the relevant industry standards.

Efficient integration of complex components with optimized layout and signal compatibility to ensure stable, high-performance PCBA designs.

We specialize in high-density component integration for complex PCBA projects. Backed by strong partnerships with global suppliers and authorized distributors, our team is experienced with a wide range of ICs, sensors, power modules, and communication chips.

From BOM analysis to layout execution, we ensure electrical compatibility, layout efficiency, and stable performance—even in space-constrained or multi-functional board designs. We proactively address issues like part conflicts, EMI, and poor thermal performance using advanced tools and proven design methods.

Our integration expertise not only boosts electrical reliability but also reduces development risk, accelerates testing, and lays a solid foundation for scalable mass production.

Our 5G base station equipment enabled fast network rollout, improving coverage and performance in record time.

Our fiber optic solutions boosted data transfer rates and reduced downtime for a major telecom provider.

We delivered quantum communication equipment that ensured highly secure data encryption for a financial client.

Our IoT boards and gateways enabled seamless real-time monitoring for a smart agriculture project, improving efficiency.

Our China-based factory is equipped with advanced SMT lines, strict quality control, and skilled technicians to ensure fast, reliable, and scalable PCBA production.

Our PCBA development process is built around compliance from day one. We design every board in accordance with key global standards, including CE, FCC, UL, ISO13485, and IATF16949, ensuring your product meets regulatory requirements across consumer, medical, industrial, and automotive sectors.

Our engineers implement design rules for EMI shielding, ESD protection, safety distances, PCB insulation spacing, and signal integrity—directly into the early design stages. This proactive approach significantly reduces the risk of certification failure, repeated testing cycles, and late-stage design revisions.

We also support pre-compliance review and documentation to streamline third-party lab submissions. With our experience, your product moves faster through certification and reaches the market sooner, with fewer obstacles and greater confidence.

We provide each client with a full set of standardized engineering documents to ensure a smooth handoff from development to production—and long-term support. Deliverables include schematics, PCB layouts, Gerber files, BOMs, pick-and-place data, assembly drawings, test plans, and firmware when needed.

All files are version-controlled and traceable, supporting internal reviews, audits, and collaboration with manufacturers and testing partners. Our documentation also covers post-launch needs like firmware updates, repairs, and hardware revisions—ensuring long-term product stability and lifecycle continuity.

With clear, professional documentation, you reduce miscommunication, speed up team onboarding, and ensure smoother operations across teams and time zones.

With over 40 years experience in the industry. We know a thing or two about PCB manufacturing.

If you can’t find what you are looking for, please don’t hesitate to get in touch directly.

Simply fill in the form and we will try to get back to you ASAP. Alternatively, you can call or email us on the details below.

long@custompcba.com

+86 18123721954

Shenzhen Bao'an District, Xixiang Street, High-tech Center

long@custompcba.com