Without flux, soldering fails to form strong, conductive joints, leading to premature circuit degradation.

Flux is a chemical cleaning agent that removes metal oxides, enhances solder flow, and ensures long-term mechanical and electrical reliability.

From Bluetooth modules to high-performance processors, soldering is the process that brings circuit boards to life. Yet, while solder and heat are well understood, flux often remains an afterthought. In reality, it’s one of the most critical components in electronics assembly. This article explores what flux is, why it matters, and how to select the right type for your soldering task—whether you’re repairing a single joint or assembling high-reliability PCBs.

What Is Solder Flux?

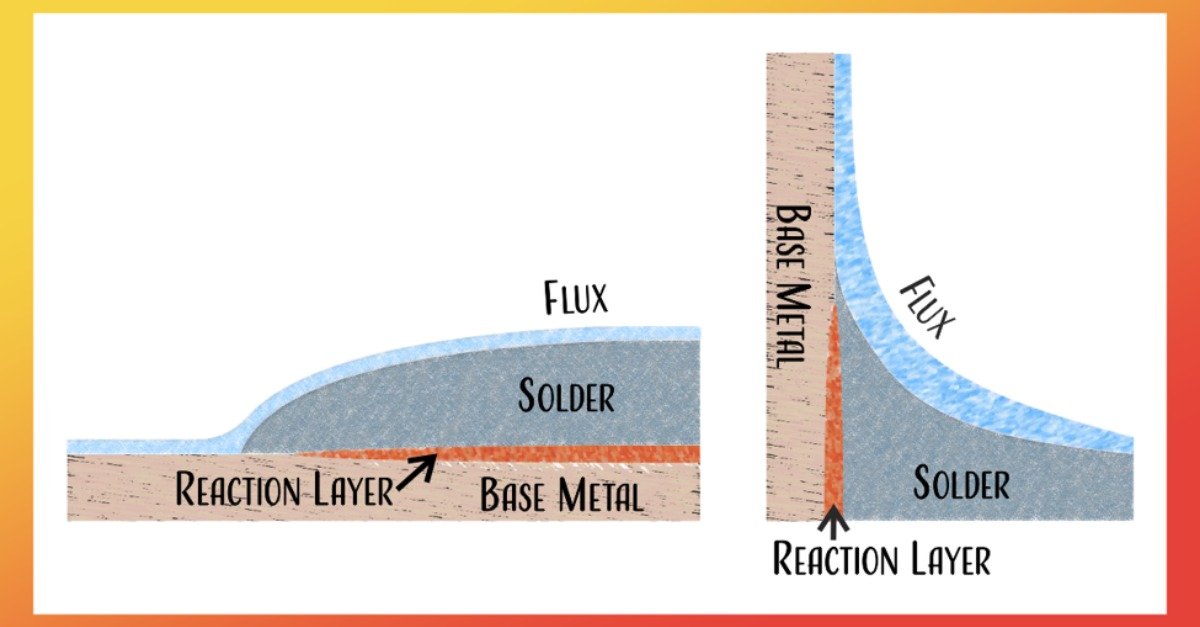

Solder flux is a chemical agent used during soldering to enhance electrical and mechanical connections. Its primary role is to remove surface oxides from metal leads and pads, preventing reoxidation by forming a protective barrier. Additionally, flux improves the wetting action of molten solder, allowing it to flow smoothly over contact areas, creating clean and durable joints.

Without flux, solder may bead, fail to bond properly, or form weak, unreliable joints that degrade over time. It is indispensable in both manual repairs and high-precision automated PCB assembly lines.

Rosin Flux

Rosin flux, or "Type R" flux, is derived from purified pine tree resin and has been used for centuries in metal joining processes. When dissolved in isopropyl alcohol, it becomes an effective, non-corrosive flux commonly used in electronics soldering.

There are three main types of rosin-based flux:

- R (Rosin): Pure rosin with no activators, ideal for low-heat applications.

- RMA (Rosin Mildly Activated): Contains a small amount of acid activators to handle moderate oxide buildup.

- RA (Rosin Activated): Stronger acid content for cleaning heavily oxidized surfaces.

While activated rosin fluxes improve cleaning efficiency, they introduce corrosive residues that must be thoroughly cleaned after soldering. These residues may contain chlorides or other halogen compounds, which can cause long-term reliability issues if left untreated.

Despite the shift toward lead-free soldering at higher temperatures, rosin flux remains popular due to its natural stability, low residue formation, and excellent wetting performance.

No-Clean Flux

No-clean flux is formulated to minimize post-soldering cleanup. It can be made from low-resin natural rosin or synthetic materials, and usually includes minimal activators to reduce residue levels. These fluxes are ideal for high-throughput production where cleaning is costly or unnecessary.

Benefits of no-clean flux:

- Leaves minimal non-corrosive residue

- Saves time and reduces processing cost

- Reduces need for post-solder cleaning

However, even no-clean fluxes can leave behind sticky or dusty residues, which may interfere with conformal coatings or sensitive inspection methods. When applying conformal coatings, boards must still be cleaned to ensure adhesion. No-clean flux is best for assemblies not exposed to harsh environments or further protective coatings.

Water Soluble Flux

Water-soluble flux (or organic flux) is designed for easy cleanup with deionized water. It uses water-based carriers and strong organic acid activators that aggressively remove oxides and promote excellent solderability.

Advantages:

- Excellent solder joint quality

- High cleaning efficiency

- Lower VOC emissions

Because these fluxes contain strong activators like halogenated compounds, thorough post-soldering cleaning is essential. Residues left behind can be corrosive and conductive, leading to potential failure. Water-soluble flux is widely used in high-reliability industries such as aerospace, automotive, and medical electronics.

The Application of Different Types of Flux

Different soldering techniques require specific types of flux to ensure proper results:

-

Wave Soldering: Boards are sprayed with flux before being passed over molten solder. The flux must contain sufficient solvent content to clean thoroughly and prevent bridging.

-

Reflow Soldering: Uses solder paste (a mix of fine solder powder and flux). The paste temporarily holds components in place, and the flux activates during heating to clean and aid solder flow.

-

Selective Soldering: Involves applying flux only to certain areas using spray or drop-jet systems, ideal for mixed-technology boards where only specific sections use through-hole components.

In all cases, flux plays a dual role: removing oxidation and improving thermal and mechanical bonding. Overapplication or overheating of flux can lead to defects like spatter, residue buildup, or joint voids.

When to Use Flux When Soldering?

Flux should be used in every soldering process where oxidation might prevent a clean metal-to-metal bond. It acts like a primer for solder, ensuring better adhesion and conductivity. Without flux, the solder may not wet properly, leading to weak or intermittent electrical connections.

Benefits of flux include:

- Removing oxide films

- Preventing reoxidation during heating

- Promoting solder spread and joint formation

- Enhancing mechanical strength and electrical integrity

Flux also shields the solder joint from air exposure during heating, further minimizing defect risk. Whether you’re soldering a new component or repairing an old board, flux ensures consistent quality.

How to Use Flux When Soldering Electronics?

Flux comes in several forms—gel, paste, and liquid—and can be applied manually or through automated dispensing. Here’s how to use it effectively:

- Clean the area to remove dust or existing residue.

- Apply a small amount of flux to the metal contacts.

- Solder the joint by heating with an iron or reflow system.

- Inspect and clean any leftover residue if needed.

Excessive flux can cause bridging or residue buildup. Acidic fluxes, while effective at cleaning, must always be removed to avoid corrosion. For clean results, liquid no-clean or tacky fluxes are often preferred, especially in manual work.

Cleaning Flux from Electronics

Proper flux removal depends on the type used:

- Rosin Flux: Requires solvents like isopropyl alcohol or specialty cleaners.

- Water-Soluble Flux: Easily removed with water and mild detergents.

- No-Clean Flux: Leaves minimal residue, but cosmetic or critical applications may still benefit from light cleaning.

Even no-clean flux can interfere with inspection systems or conformal coating. For high-reliability assemblies, post-solder cleaning is recommended regardless of flux type.

What is the Difference Between Solder Flux and Solder Paste?

While both aid soldering, solder flux and solder paste serve different functions:

| Property | Solder Flux | Solder Paste |

|---|---|---|

| Form | Liquid or gel | Thick paste |

| Composition | Activators, solvents, resin | Solder powder + flux |

| Usage | Cleaning and wetting | Holds components + wets solder |

| Cleaning | May be required | Often leaves more residue |

| Activation | Pre-applied or sprayed | Activates during reflow |

Solder paste is generally used in SMT reflow soldering, while separate flux is used in hand soldering, rework, or wave soldering.

Alternatives to Soldering Flux

While flux is ideal, a few household substitutes can be used in emergencies:

- Petroleum Jelly (Vaseline): Works as a mild flux, is non-corrosive, and helps remove oxide layers.

- Lemon Juice: Citric acid acts as a weak cleaning agent.

- DIY Rosin or Pine Tar Flux: Possible to make if you have access to raw pine rosin.

However, these are less reliable than commercial options and not suitable for precision or high-reliability electronics. Always pre-clean surfaces and understand the limitations of DIY flux substitutes.

Can You Use Vaseline as Flux?

Yes, Vaseline (petroleum jelly) can function as a basic flux. It helps remove oxides, protects against air exposure, and is non-corrosive. It’s a viable option for quick fixes or basic repairs but lacks the cleaning power and precision of true electronic-grade flux.

Are There Other Alternatives to Commercial Flux?

Other flux alternatives include:

- Lemon Juice: Useful in very small jobs due to citric acid content.

- Homemade Colophony: Crushed pine resin mixed with isopropyl alcohol can work as an emergency rosin flux.

- Organic compounds: Like vinegar or sugar-based gels, though generally too mild or inconsistent for PCB work.

For critical applications, it’s always best to use purpose-built flux formulations.

Conclusion

Flux plays an indispensable role in soldering by cleaning metal surfaces, preventing oxidation, and enhancing solder flow. While alternative materials like Vaseline or lemon juice can substitute in certain situations, dedicated flux is essential for high-quality, reliable solder joints. Whether you’re a hobbyist or working in a manufacturing environment, selecting the right flux—and knowing how to use and clean it properly—is key to maintaining electronic performance and durability.