Circuit boards are critical components in many electronic devices, such as smartphones and smart home products, and their performance directly impacts the efficiency of the devices. However, due to environmental factors, usage conditions, and other uncontrollable elements, circuit boards may suffer from corrosion, affecting the functionality and reliability of the devices.

The presence of corrosion on circuit boards not only leads to performance degradation but can also cause permanent damage to the equipment. Therefore, understanding how to effectively remove corrosion from circuit boards is essential. In this article, we will explore the causes of circuit board corrosion, the best practices for removing corrosion, and how to prevent future corrosion issues.

Are you ready to dive into these topics? Let’s get started!

Are you ready to dive into these topics? Let’s get started!

Although circuit boards are typically hidden within many critical devices, the incidence of their pollution and dirt accumulation is quite common. Whether in consumer electronics or industrial equipment, circuit boards are exposed to various pollutants in the environment, which have long affected their performance and reliability.

Sources of Contaminants

Nearly all devices have small gaps that allow air and dust to enter their interiors. These dust particles, debris, and other contaminants eventually accumulate on the surface of the circuit board, forming dirt and accelerating corrosion under humid conditions.

Larger devices often have fans for heat dissipation, which not only prevents overheating but can also draw in more dust and dirt, leading to significant soiling of the circuit board.

Two Main Types of Contaminants

- Dry Contaminants: The most common pollutants are dust and small particulate matter, which continually settle on circuit boards through the air. While these pollutants are relatively easy to clean, neglecting them for an extended period can still lead to a decline in the surface performance of the circuit board.

- Wet Contaminants: Moisture, liquid leaks, dirt, soldering residues, and chemicals (such as soda and wax) fall under the category of wet contaminants. These pollutants not only affect the electrical performance of circuit boards but can also lead to long-term corrosion, further damaging the equipment.

Deeper Causes of Circuit Board Corrosion

Before delving into how to remove corrosion from circuit boards, it is crucial to understand the fundamental reasons behind such corrosion. This knowledge will help you take effective preventive measures to avoid the accumulation of corrosion.

In various environmental conditions, airborne chemicals interact with the metallic materials within circuit boards, such as aluminum and copper. Over time, these reactions cause oxidation on the metal surfaces, leading to corrosion.

Additionally, accidental spills or leaks of liquids are common causes of corrosion. Whether due to environmental humidity or liquid seepage within the device, the presence of liquid accelerates the corrosion process of the circuit board, impacting its normal operation.

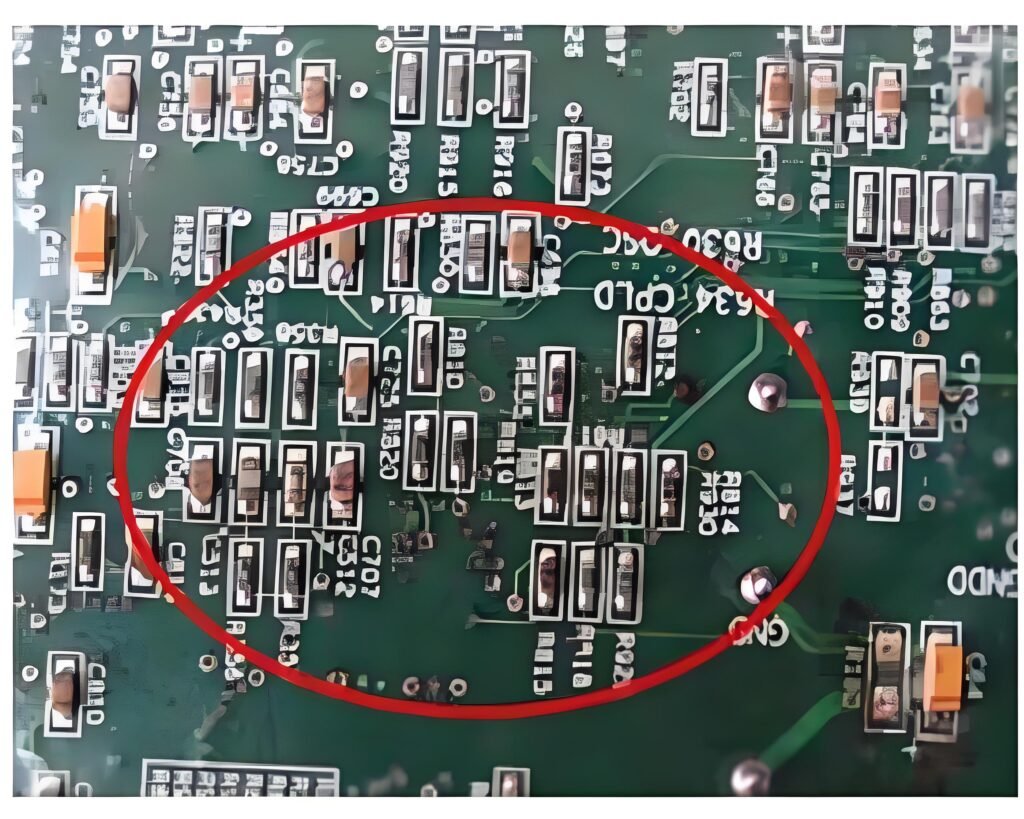

The most common and direct consequence is rust, which not only reduces the electrical performance of the circuit board but may also lead to short circuits and severe damage to the equipment. Frequent corrosion and rust can cause circuit connections to fail, resulting in permanent damage to the device.

Understanding the causes of circuit board pollution and corrosion is the first step in maintaining device performance. By regularly inspecting and taking appropriate preventive measures, you can effectively extend the lifespan of circuit boards and ensure the reliability and efficiency of your equipment.

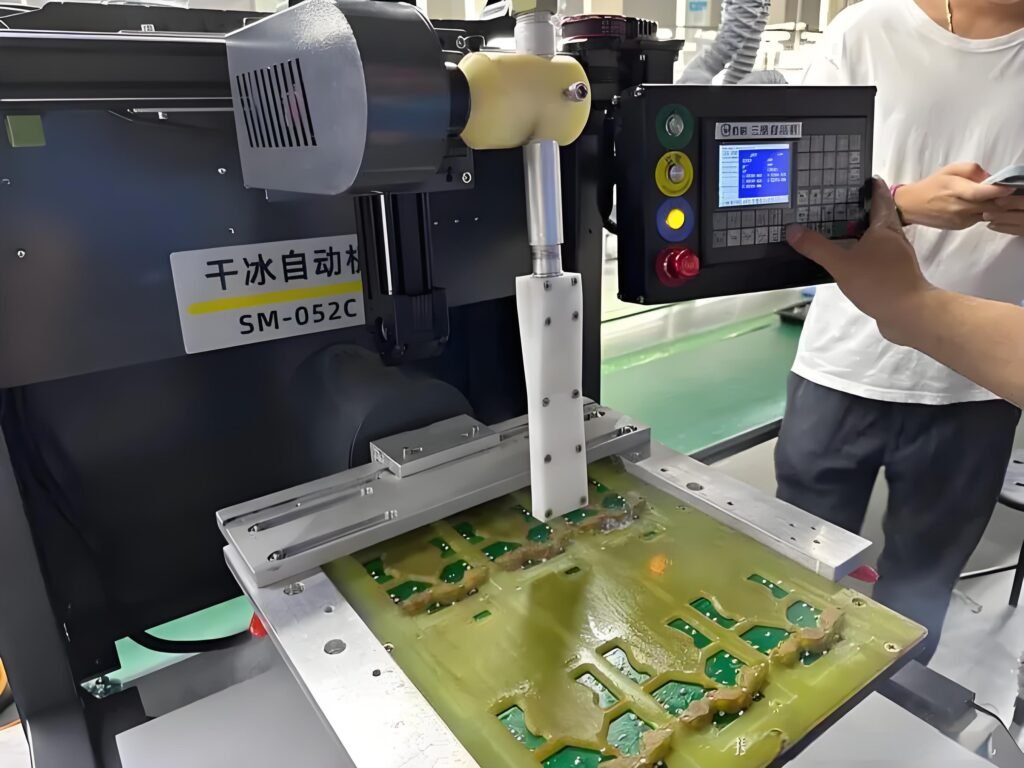

Effective Methods for Removing Corrosion from Circuit Boards

When it comes to eliminating corrosion from electronic devices, a variety of chemical solutions are available. These chemicals can address issues ranging from natural rust to severe corrosion, depending on their acidic strength. In this guide, we will delve into the necessary tools and the comprehensive steps involved in cleaning corroded circuit boards.

Safety Precautions for Circuit Board Cleaning

Before you begin the corrosion removal process on a circuit board, it’s crucial to follow safety measures:

- Power Disconnection: Ensure that the device is completely powered off and disconnected from any power source.

- Battery Removal: Carefully remove the battery and store it separately to prevent any electrical hazards.

- Avoid Water: Steer clear of using water during the cleaning process. Ensure that your hands and cleaning cloths are dry to avoid any additional moisture exposure.

- Glove Protection: If you plan to use isopropyl alcohol, consider wearing gloves to protect your skin.

- Gentle Handling: Handle the circuit board delicately to avoid damaging any components. Do not force any cleaning steps.

- Take Your Time: Patience is key. Rushing through the cleaning process can lead to further damage or missed areas.

Chemical and Non-Chemical Solutions for Removing Corrosion

For most corrosion cleaning tasks, compressed air can be highly effective. It successfully removes dirt and debris from the circuit board surface. However, in cases of significant corrosion, distilled water or isopropyl alcohol may be required. Below, we will explore each option in more detail.

- Compressed Air: A can of compressed air is an excellent tool for routine maintenance of circuit boards. It can prevent corrosion and rust by blowing away dust and contaminants. Direct the compressed air nozzle toward the rusted areas through the device’s ventilation openings. The high-pressure air effectively lifts away most dirt and debris, and it can also help remove minor rust spots.

- Baking Soda: Baking soda, or sodium bicarbonate, is an effective agent for cleaning circuit boards. It works by breaking down dirt and grime into smaller particles, making it easier to remove. Create a paste with water and apply it to the affected areas. Allow it to sit briefly before gently scrubbing with a soft brush, then rinse with distilled water.

- Distilled Water: If you need to create a chemical solution to tackle corrosion, distilled water is the best choice. Its purification process removes harmful impurities, ensuring it does not damage the printed circuit board (PCB). Use distilled water in conjunction with other cleaning agents for optimal results.

- Isopropyl Alcohol: Commonly known as rubbing alcohol, isopropyl alcohol is a traditional cleaner used by many to remove residues, flux, dust, and corrosion from various components. It should be considered a last resort for severe corrosion. Opt for a concentration of at least 90% isopropyl alcohol for effective cleaning. Use it only when distilled water, baking soda, or compressed air fail to resolve the corrosion issue.

Cleaning corrosion from circuit boards is essential for maintaining the functionality and longevity of electronic devices. By utilizing a combination of safe practices and effective cleaning agents, you can restore your circuit boards to optimal condition. Regular maintenance and timely intervention can prevent the accumulation of corrosion, ensuring your devices continue to operate efficiently.

Tools Required for Removing Corrosion from Circuit Boards

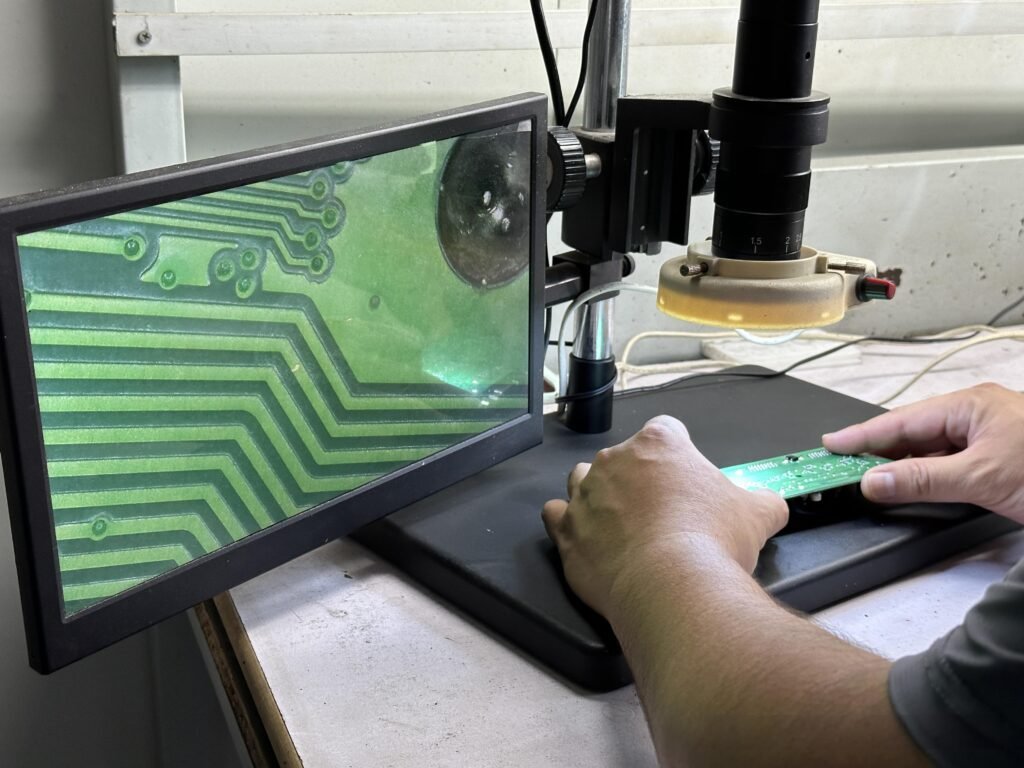

When preparing to remove corrosion from circuit boards, selecting the right tools is crucial. Here are some recommended tools that can help you effectively and safely complete the cleaning task.

1. Microfiber Cloth or Professional Cleaning Cloth

To remove chemical solutions, such as isopropyl alcohol or baking soda, applied on the circuit board, it is essential to choose high-quality microfiber cloth. This type of fabric does not shed lint, helping to minimize residues and ensure effective surface cleaning. Additionally, microfiber cloths offer better protection for circuit board surfaces, preventing scratches or damage during cleaning.

2. Specialized Cleaning Brush

A soft-bristle cleaning brush is ideal for removing rust and corrosion from the circuit board. The bristles should be soft yet dense, allowing for deep cleaning in small crevices without scratching the circuit board. Choosing the right brush not only enhances cleaning efficiency but also ensures safety throughout the cleaning process.

3. Hair Dryer or Heat Gun

After cleaning, it is crucial to ensure that the circuit board is completely dry. To achieve this, using a hair dryer or heat gun can effectively remove any residual liquid. Adjust the appropriate temperature to avoid overheating, which could damage the circuit board. Alternatively, you can also use a desk lamp or a preheated oven, gently wrapping the circuit board in aluminum foil to help evaporate excess moisture.

4. Compressed Air Can

Compressed air is a powerful tool that can be used to remove dust and small particles from the surface and crevices of the circuit board. Before cleaning, use a can of compressed air to blow away loose dirt, ensuring that the circuit board surface is clean and preventing secondary contamination during subsequent cleaning.

5. Precision Tweezers

When handling circuit boards, precision tweezers can help you accurately locate and remove small corrosion or contaminants. This tool is especially useful for accessing hard-to-reach small areas, ensuring that every detail is addressed.

6. Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) during any cleaning operation is very important. This includes gloves and safety goggles to protect yourself from chemicals and small particles. Using PPE not only promotes safe operation but also enhances the professionalism of the cleaning process.

Choosing the right tools and safety measures is key to ensuring the cleaning and maintenance of circuit boards. By using these professional tools, you will be able to more effectively remove corrosion and contamination, thereby extending the lifespan of electronic devices and improving their performance. Regular inspection and cleaning of circuit boards will help prevent issues, ensuring that your devices remain in optimal condition.

Steps to Remove Corrosion from Circuit Boards

Corrosion on circuit boards is a significant issue that can affect the performance and longevity of electronic devices. It can lead to poor connections and may ultimately result in device failure. To effectively remove corrosion from a circuit board, it’s essential to follow a systematic approach. These steps not only assist in cleaning the circuit board but also help protect its critical components during the process.

1. Disassemble the Device

Start by carefully disassembling the device. Ensure that the device is completely disconnected from any power source, including unplugging the charging port. Remove the battery first to avoid any electrical hazards. Use the appropriate screwdriver to detach various components to access the printed circuit board (PCB).

Follow the instructions in the user manual during the disassembly. To avoid confusion during reassembly, take clear photos of each step. Additionally, watching tutorial videos on platforms like YouTube can help you better understand the disassembly process. Be sure to use the specified screwdriver to prevent damaging screws or other parts.

2. Prepare the Cleaning Solution

Once you have access to the circuit board, you can prepare the cleaning solution. It is recommended to create a cleaning agent by mixing distilled water with baking soda. Combine half a cup of distilled water with 1-2 tablespoons of baking soda until a thick paste forms. This solution effectively breaks down corrosion and dirt.

3. Apply the Cleaning Solution

Using a soft-bristle brush, apply the baking soda paste to the corroded areas of the circuit board. Allow the solution to sit for about 10-15 minutes to soften the corrosion and dirt. This step is crucial, as it facilitates the subsequent cleaning process.

4. Gently Brush the Corroded Areas

After letting the solution sit, gently brush away the corrosion. Be careful not to apply too much pressure, as this could damage the sensitive components on the circuit board. As you brush, the corrosion and debris should gradually come off.

5. Rinse the Circuit Board

After brushing, rinse the circuit board with distilled water to remove any remaining cleaning agent and dirt. Ensure that no cleaning solution residue remains, as this could lead to further corrosion or damage.

6. Use Isopropyl Alcohol for Stubborn Residue

If there are still remnants of corrosion or dirt on the circuit board, consider using household cleaners or isopropyl alcohol. Apply a few drops of isopropyl alcohol to the affected area and let it sit for about 15-20 seconds. Then, use a soft brush to clean away any remaining rust or residue.

7. Dry the Circuit Board

Finally, ensure the circuit board is completely dry. Use a hairdryer or air dryer to gently heat the circuit board, helping to evaporate any moisture. Thoroughly drying the circuit board is key to preventing future corrosion issues.

By following these detailed steps, you can effectively remove corrosion from your circuit board while ensuring the safety and integrity of its components. Regular maintenance and cleaning of circuit boards can extend the lifespan of electronic devices, enhance their performance, and prevent further corrosion problems. Throughout the cleaning process, always handle components carefully and take appropriate safety precautions.

Conclusion

In summary, this comprehensive guide provides you with effective strategies for removing corrosion from circuit boards. We have explored a wide range of solutions, including both chemical and non-chemical methods, to effectively eliminate debris, dirt, and rust from your circuit boards.

The detailed step-by-step instructions, coupled with the recommended drying procedures, will empower you to tackle corrosion effectively. It’s essential to emphasize the importance of keeping your devices away from moisture sources, as water accumulation is a primary catalyst for corrosion on PCBs.

Taking proactive measures and adhering to proper cleaning protocols can significantly extend the lifespan of your electronic devices, ensuring optimal performance and reliability. Regular maintenance not only enhances functionality but also prevents costly repairs or replacements down the line.

By following this guide, you can maintain the integrity of your circuit boards and protect your valuable electronic equipment. Always remember to handle all components with care and prioritize safety throughout the cleaning process.