In-Depth Analysis of Modern Printed Circuit Boards

In-Depth Analysis of Modern Printed Circuit Boards

Printed Circuit Boards (PCBs) are essential components found in nearly all electronic devices, including smartphones, home appliances, and medical equipment. Typically constructed from non-substrate materials, PCBs feature multiple layers of copper circuits internally to meet various functional requirements.

Depending on the complexity of the design, PCBs can be categorized into several types: single-sided PCBs, double-sided PCBs, and multilayer PCBs. Single-sided PCBs are suitable for simple circuits, while double-sided PCBs offer greater flexibility in electrical connections, making them ideal for medium-complexity applications. Multilayer PCBs, usually consisting of 4 to 50 or more layers of copper circuits, support high-density connections and complex signal processing, making them perfect for modern high-performance electronic devices.

Material selection is crucial for PCB performance. Common substrates include FR-4, polyimide, and ceramics, which not only ensure circuit stability but also meet operational requirements across various temperatures and environmental conditions. Additionally, surface treatment techniques such as gold plating and tin spraying further enhance the circuit’s corrosion resistance and conductivity.

In summary, choosing the appropriate type and materials for PCBs is vital to ensure the efficient and reliable operation of electronic devices. It warrants thorough exploration and understanding, and we will discuss the different PCB materials and how they can benefit you.

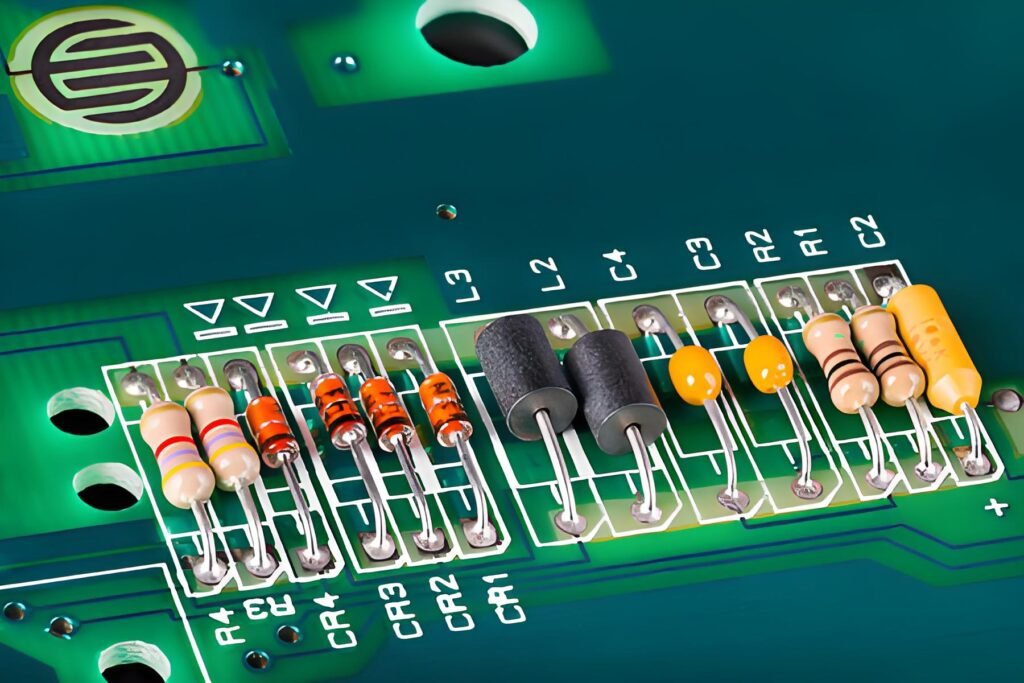

Key Electronic Components in Printed Circuit Boards

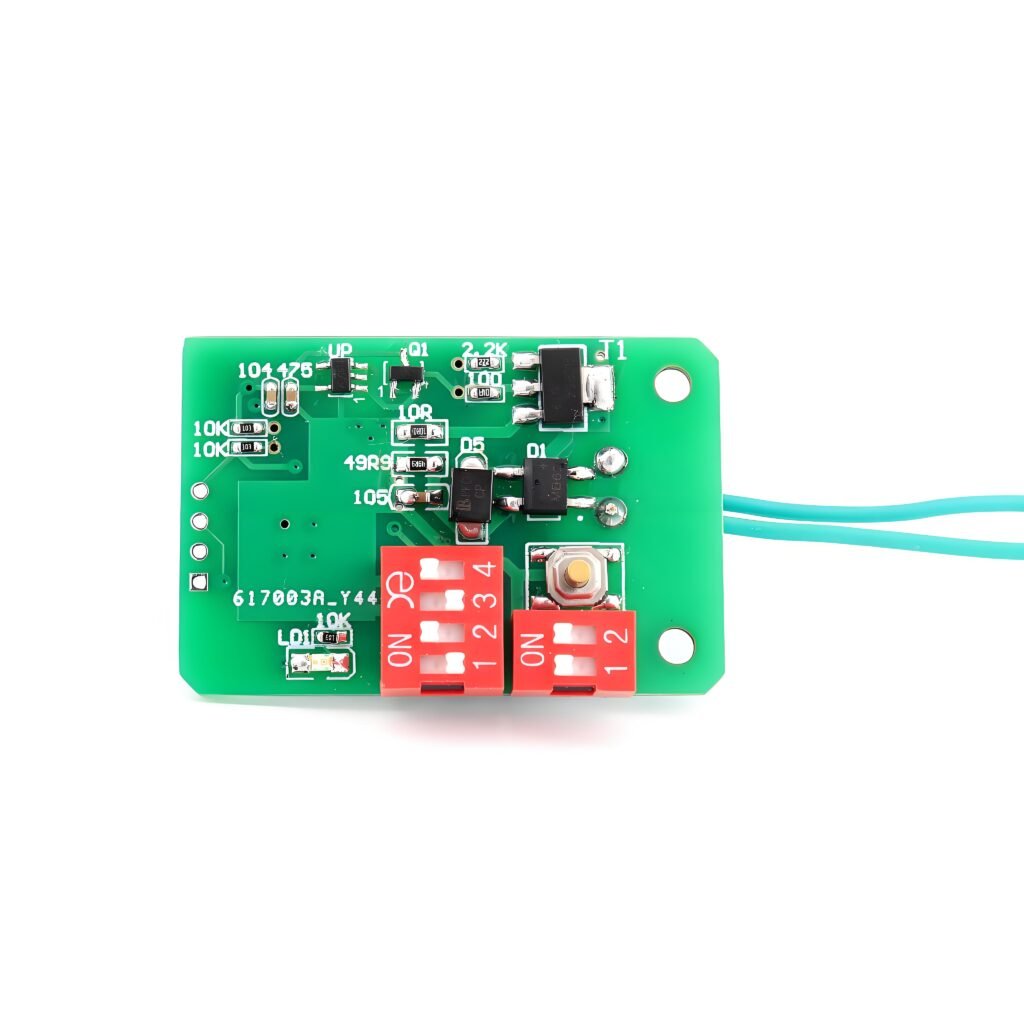

Printed Circuit Boards (PCBs) are the foundation of modern electronic devices, composed of various materials and electronic components. Below are some of the important components commonly found on PCBs:

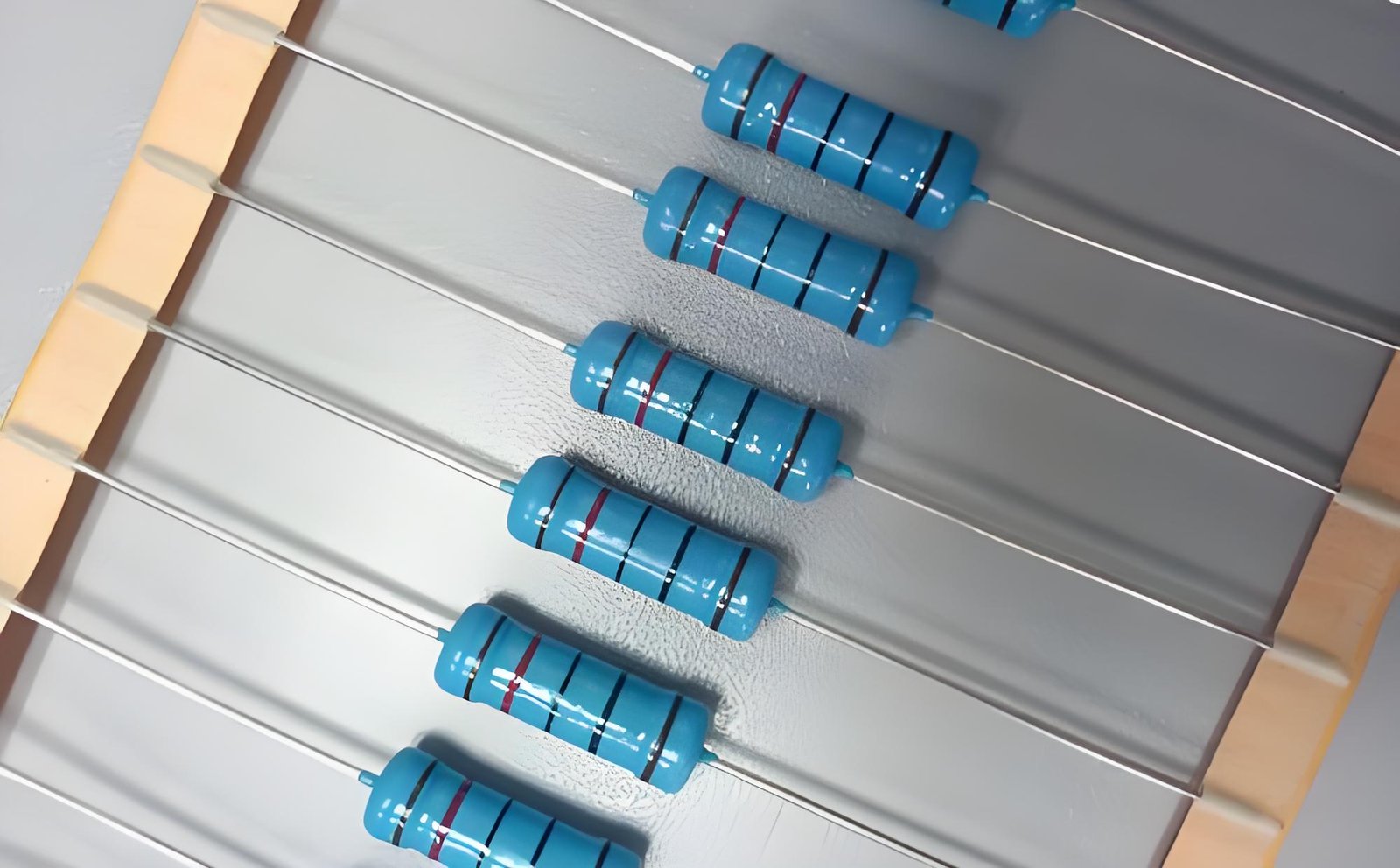

Basic Functions and Material Properties of Resistors

Resistors are key components in circuit design, primarily used to control the flow of current, create voltage drops, and dissipate excess electrical energy as heat, thereby ensuring the stability and safety of the circuit. As one of the fundamental electronic components, resistors are ubiquitous in modern electronic devices, and their importance cannot be underestimated.

Operating Principle

The function of a resistor is based on Ohm’s Law (V = I × R), where V represents voltage, I represents current, and R is the resistance value. By selecting the appropriate resistance value, designers can precisely adjust the current to meet specific circuit requirements. This precise control is fundamental to electronic design, effectively ensuring the normal operation of the circuit.

Material Composition

Resistors are made from a variety of materials, primarily including:

- Carbon Film: Suitable for most standard applications, offering a good balance of performance and stability, widely used in everyday electronic products.

- Metal Film: Provides higher precision and temperature stability, making it suitable for applications with stringent resistance requirements, commonly found in high-end electronic devices.

- Wirewound: Designed for high-power environments, effectively managing heat while providing high durability, ideal for power amplifiers and high-current circuits.

Resistors are not just simple components; their design, materials, and specifications directly influence the overall performance of the circuit. By judiciously selecting resistors, engineers can ensure the reliability and stability of circuits under various operating conditions. In summary, resistors play a crucial role in circuits, serving as the foundation for achieving complex electronic functions.

Basic Functions and Operating Principles of Capacitors

Capacitors are essential components in circuit design, primarily functioning to store electrical charge and release power when needed in the circuit. As energy storage devices, capacitors play a significant role in signal processing, filtering, and power management.

The operating principle of a capacitor is based on the formation of an electric field and the accumulation of charge. It consists of two conductive layers and an insulating material known as the dielectric. When a capacitor is connected to a power source, positive and negative charges accumulate on the two conductive layers, creating an electric field. The capacitance (C) of a capacitor indicates its ability to store charge, measured in farads (F), and can be calculated using the formula C=QVC = \frac{Q}{V}C=VQ, where Q is the amount of stored charge and V is the voltage.

Materials and Types

Capacitors can be classified into various types based on their dielectric materials and construction, primarily including:

- Ceramic Capacitors: Widely used in high-frequency and low-power circuits, offering excellent temperature and voltage stability.

- Aluminum Electrolytic Capacitors: Characterized by high capacitance, suitable for low-frequency applications such as power stabilization and filtering.

- Film Capacitors: Provide good stability and low loss, ideal for high-precision applications.

The choice of capacitor directly impacts the performance and efficiency of the circuit. When designing circuits, engineers must select the appropriate type and specifications of capacitors based on specific application requirements to ensure the reliability and stability of the circuit under various operating conditions.

In summary, capacitors are not only crucial energy storage elements in circuits, but a deep understanding of their structure and operating principles is vital for optimizing the design of electronic devices.

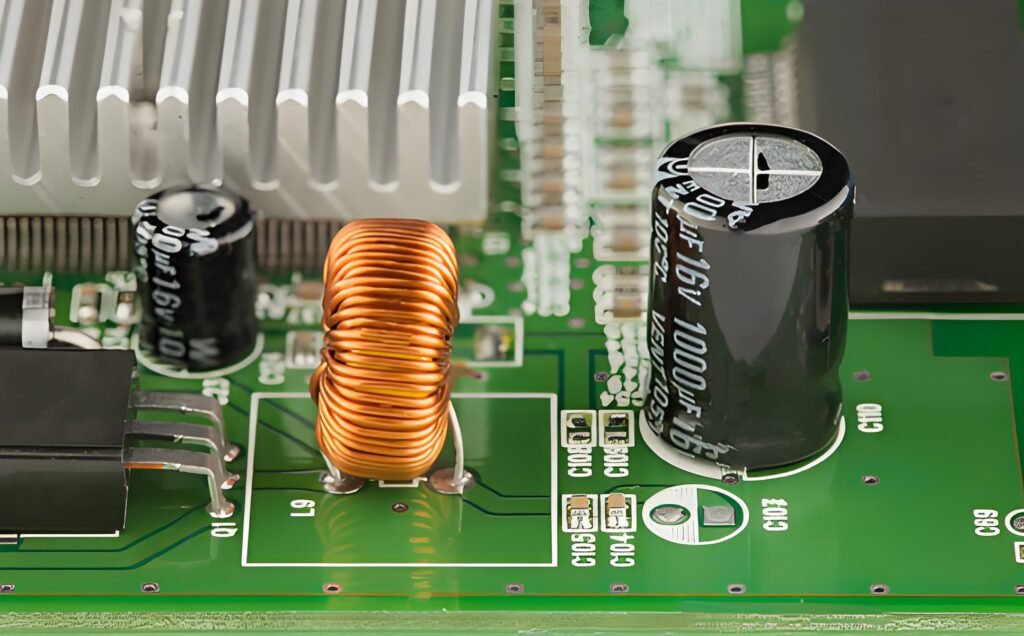

Basic Functions and Operating Principles of Inductors

Inductors are important components in circuit design, similar to capacitors, as they can store energy but are primarily used to control and regulate current. In printed circuit boards (PCBs), inductors are commonly employed to suppress interference signals, ensuring circuit stability and signal integrity.

Operating Principle

The operating principle of an inductor is based on electromagnetic induction. It consists of a coil of wire wound around a core, either made of iron or air. When current flows through the coil, it generates a magnetic field around it. As the current changes, the magnetic field also changes, inducing a self-induced electromotive force (EMF) within the inductor that opposes the change in current. This characteristic enables inductors to effectively filter out high-frequency interference and provide instantaneous energy storage during current transients.

Materials and Types

Inductors can be categorized into various types based on their structure and materials, primarily including:

- Air-Core Inductors: Typically made from wire coils without a core, suitable for high-frequency applications.

- Iron-Core Inductors: Enhance the magnetic field by adding a core, suitable for low-frequency and high-power applications.

- Common-Mode Inductors: Used to suppress common-mode noise, commonly found in power supply and signal processing circuits.

The selection of inductors in a circuit is crucial for interference suppression and energy management. Designers need to choose the appropriate type and specifications of inductors based on specific application requirements to ensure stability and efficiency of the circuit under varying operating conditions.

In summary, inductors are essential energy storage elements in circuits. Their unique operating principles and wide range of applications make them an indispensable part of electronic design. A deeper understanding of the functions and characteristics of inductors aids in optimizing the overall performance of electronic devices.

Basic Functions and Operating Principles of Transistors

Transistors are fundamental components in modern electronic circuits, primarily used for amplifying and switching electronic signals. As semiconductor devices, transistors play a crucial role in signal processing, power amplification, and digital logic circuits.

Operating Principle

The operating principle of a transistor is based on semiconductor physics, typically divided into three main regions: the emitter, base, and collector. By applying a small current to the base, a larger current flowing between the emitter and collector can be controlled. This amplification effect allows transistors to achieve signal gain and switching functions. Common types of transistors include:

- Bipolar Junction Transistor (BJT): Operates using the recombination of electrons and holes, available in NPN and PNP types, suitable for both analog and digital circuits.

- Field-Effect Transistor (FET): Controls current through an electric field, characterized by high input impedance and low power consumption, making it ideal for high-frequency applications.

Materials and Characteristics

The primary materials used in transistors are silicon (Si) or germanium (Ge), with silicon being more commonly used due to its superior thermal stability and electrical properties. Key performance metrics for transistors include gain, operating frequency, and input/output impedance, all of which directly impact their performance in circuits.

The selection of transistors is critical for the functionality and efficiency of a circuit. During the design process, engineers must choose the appropriate type of transistor based on application requirements to ensure accurate signal processing and system reliability.

As key components in electronic circuits, transistors play a vital role in signal amplification and switching. A deep understanding of their characteristics and applications is essential for optimizing the design and performance of electronic devices.

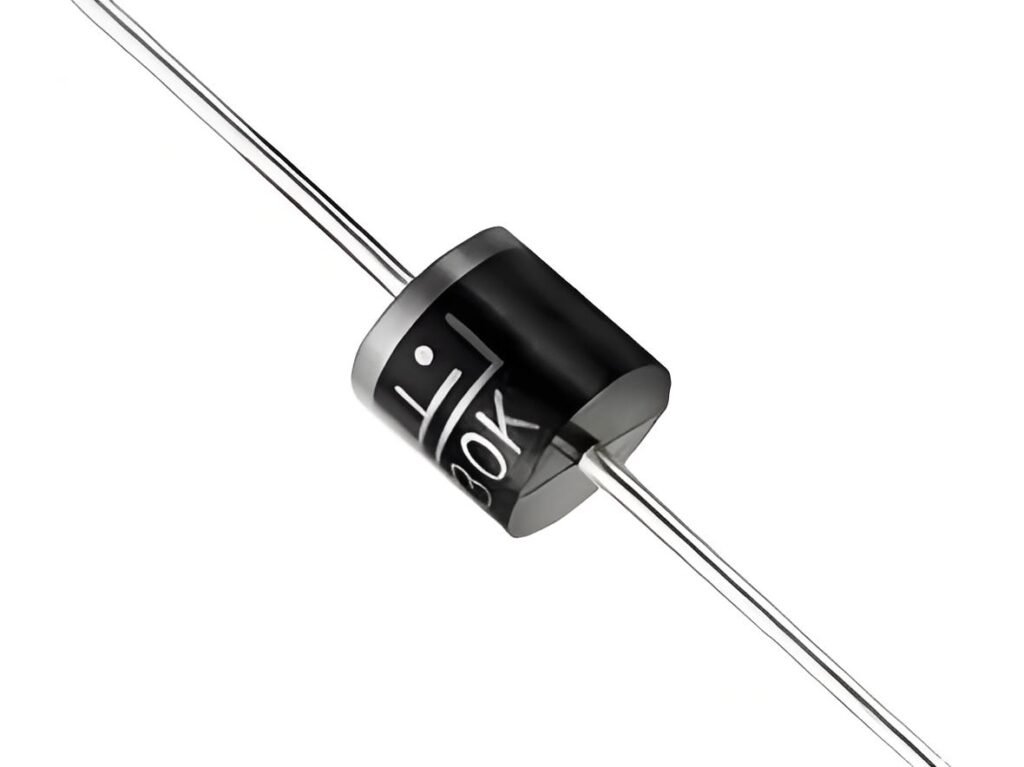

Basic Functions and Operating Principles of Diodes

Diodes are fundamental components in electronic circuits, primarily used to control the direction of current. By allowing current to flow in one direction while blocking it in the reverse direction, diodes play a critical role in protecting circuits and implementing signal rectification.

Diodes are composed of two types of semiconductor materials (P-type and N-type), forming a PN junction. When a forward voltage is applied to the diode, electrons and holes recombine in the PN junction region, allowing current to flow; conversely, when a reverse voltage is applied, the electric field in the PN junction area prevents current from flowing, achieving unidirectional conductivity. This characteristic enables diodes to effectively prevent reverse current flow, protecting the circuit and other components.

Materials and Types

The primary material used in diodes is silicon (Si), although other materials such as germanium (Ge) and gallium nitride (GaN) are also utilized. Common types of diodes include:

- Rectifier Diodes: Used for current rectification, commonly found in power supply circuits.

- Zener Diodes: Designed specifically for voltage regulation, capable of maintaining a constant voltage under reverse bias.

- Light Emitting Diodes (LEDs): Emit light when current passes through, serving as important components in lighting and indication applications.

The selection of diodes is crucial for the safety and functionality of a circuit. Designers must consider parameters such as maximum reverse voltage, forward current, and response speed to ensure effective application in the circuit.

As key components in circuits, diodes not only play an important role in current control and protection but also require a deep understanding of their principles and characteristics to enhance the performance and reliability of electronic devices.

Basic Functions and Operating Principles of Sensors

Sensors are critical components in modern electronic systems, primarily used to detect changes in environmental conditions and convert these changes into corresponding electrical signals. These electrical signals are then transmitted to other components on the circuit board for intelligent response and control.

Operating Principles

The operating principles of sensors depend on their type and design. Generally, sensors respond to physical quantities in the environment (such as light, temperature, humidity, pressure, and motion) and convert them into electrical energy. This conversion process typically involves the following steps:

- Sensing: The sensitive elements within the sensor react to external stimuli (such as light or temperature).

- Conversion: The detected physical quantity is transformed into an electrical signal through the sensor’s conversion mechanism (such as the photoelectric effect or thermoelectric effect).

- Output: The generated electrical signal is then sent to processors or other components on the circuit board for further processing.

Materials and Types

There is a wide variety of sensors, each with different materials and technologies, including:

- Light Sensors: Such as photodiodes or photoresistors, specifically designed to detect light intensity.

- Temperature Sensors: Such as thermocouples or thermistors, used to measure temperature changes.

- Gas Sensors: Used to monitor air quality by detecting the concentration of specific gases.

- Sound Sensors: Such as microphones, capable of converting sound waves into electrical signals.

The selection of sensors is crucial for the performance and response speed of the system. When designing circuits, engineers must choose the appropriate type and sensitivity of the sensor based on specific application needs to ensure accurate environmental monitoring and control.

Sensors are not only essential tools for environmental perception; their conversion principles and diverse applications make them indispensable in electronic devices. A deep understanding of sensor functions and characteristics helps optimize the design and performance of intelligent systems.

Composition and Functions of Common PCB Layers

The design of printed circuit boards (PCBs) typically includes multiple layers, each playing an important role in the overall functionality. While different types of PCBs may have varying numbers of layers and constructions, all PCBs contain the following four basic layers:

Substrate Layer

The substrate layer is the supporting structure of the PCB, usually made from fiberglass (such as FR-4 material) to provide sufficient rigidity and stability to the circuit board. Although some PCBs may use epoxy resin as the substrate, it generally lacks the durability and mechanical strength of fiberglass. The choice of substrate layer directly affects the PCB’s thermal resistance, thickness, and reliability.

Copper Layer

The copper layer is the conductive part of the PCB, typically laminated onto the substrate layer using thin copper foil through thermal pressing. Depending on the design requirements, the thickness and number of copper layers may vary. Single-sided PCBs provide one layer of copper on one side, while double-sided PCBs have conductive copper layers on both sides. For high-power PCBs, thicker copper layers are usually required to ensure good current-carrying capacity and thermal management.

Solder Mask Layer

The solder mask layer is located on top of the copper layer, primarily serving as insulation and protection. This layer is typically green and prevents the copper layer from contacting the external environment, reducing the risk of oxidation and short circuits. The presence of the solder mask layer ensures a smooth soldering process and enhances the reliability of the circuit board.

Silkscreen Layer

The main function of the silkscreen layer is to provide a user interface, making the PCB’s usage more intuitive. By printing letters, numbers, and symbols on the surface of the PCB, the silkscreen layer helps users identify different pins, LEDs, and other components’ functions. This labeling not only improves maintenance convenience but also reduces the likelihood of operational errors.

In summary, the layered structure of PCBs not only determines their electrical performance and mechanical strength but also has a profound impact on the overall reliability and usability of the circuit board. A deeper understanding of these basic layers’ functions and constructions can aid in optimizing PCB design and application.

Types of Printed Circuit Boards and Their Material Composition

Printed circuit boards (PCBs) are the core of modern electronic devices, and their design and material selection directly impact circuit performance and reliability. Different types of PCBs are suitable for various applications, each with its own characteristics in materials and structures. Below is a detailed introduction to the most common types of PCBs and their constituent materials:

Single-Sided PCB

Single-sided PCBs are the most basic type of printed circuit board, featuring conductive material on only one side. This type typically consists of a substrate layer (such as fiberglass), a conductive copper layer, a protective solder mask, and a silkscreen layer. Single-sided PCBs have a simple design and relatively low cost, making them suitable for various electronic devices such as home appliances, printers, and audio equipment.

Double-Sided PCB

Double-sided PCBs allow for the installation of conductive copper layers on both sides, enabling more complex circuit designs. Their structure includes a substrate layer, copper layers on both sides, a solder mask, and a silkscreen layer. Components on both sides are connected using surface mount technology or through-hole technology. The design flexibility of double-sided PCBs makes them popular in applications like lighting devices and automotive dashboards.

Multilayer PCB

Multilayer PCBs consist of at least three conductive layers separated by insulating material, forming a “sandwich” structure. This design allows multilayer PCBs to accommodate more complex circuits within a limited space, making them widely used in high-end products such as computers, medical devices, and GPS trackers.

Rigid PCB

Rigid PCBs are sturdy and inflexible circuit boards, typically made by bonding multiple layers of materials together using adhesives and heat. They can be single-sided, double-sided, or multilayer, offering good durability and cost-effectiveness for mass production, making them suitable for applications with fixed components.

Flexible PCB

Flexible PCBs use plastic materials (such as Kapton) as the substrate, designed to provide excellent flexibility and durability. Their design allows them to operate effectively in confined spaces, withstand extreme temperatures, and be compatible with various components, making them ideal for mobile devices and applications with complex shapes.

Rigid-Flex PCB

Rigid-flex PCBs combine the characteristics of rigid and flexible PCBs, allowing for bending or folding as needed. Utilizing 3D design, these circuit boards can take on specific shapes according to product requirements, making them an ideal choice for lightweight solutions.

High-Density Interconnector PCB (HDI PCB)

HDI PCBs are a type of PCB with high circuit density, featuring smaller hole sizes and blind hole designs. This enables designers to arrange components more closely, enhancing signal transmission speed and reducing signal loss, making them widely used in smartphones and high-performance gaming consoles.

LED PCB

LED PCBs are specifically designed for light-emitting diodes (LEDs) and are suitable for various lighting applications. By installing multiple LEDs on the PCB, users can achieve precise lighting control, making them widely applicable in automotive lighting and other industries.

Blank PCB

Blank PCBs are circuit boards that have not been assembled with any components, typically used for later assembly and manufacturing. They are made of durable substrates (such as silicon) and copper layers, ensuring good electrical conductivity, serving as the foundation for design and assembly processes.

Custom PCB

Custom PCBs offer greater flexibility and control based on project requirements. They are suitable for applications that require complex designs or cost-effectiveness, providing specialized solutions for industry clients.

By gaining a deeper understanding of these different types of PCBs and their material compositions, you can better select the circuit board that meets your specific needs, ensuring optimal performance and reliability in your products.

Final Summary

We have accumulated extensive experience in designing various types of printed circuit boards (PCBs), including single-sided, double-sided, and multilayer boards. Whether you need custom designs to specific specifications or want us to develop PCBs that meet industry standards, we can provide the most suitable material recommendations and solutions for your project.

From conceptual design to final assembly, we offer a one-stop PCB service, ensuring efficiency and precision at every stage. When you choose to work with us, you will enjoy the fastest delivery times in the UK, ensuring your project progresses on schedule. For more information, please contact our team. Simply fill out the form, and we will respond promptly.

Get your free professional quote today! Whether you need custom design, manufacturing, or PCB assembly services, we are here to help you achieve and exceed your project goals. We look forward to your feedback and requirements. Contact us now!