SMT assembly vs through-hole is one of the most important comparisons in circuit board manufacturing. But what sets these two methods apart, and how do you choose the right one for your project?

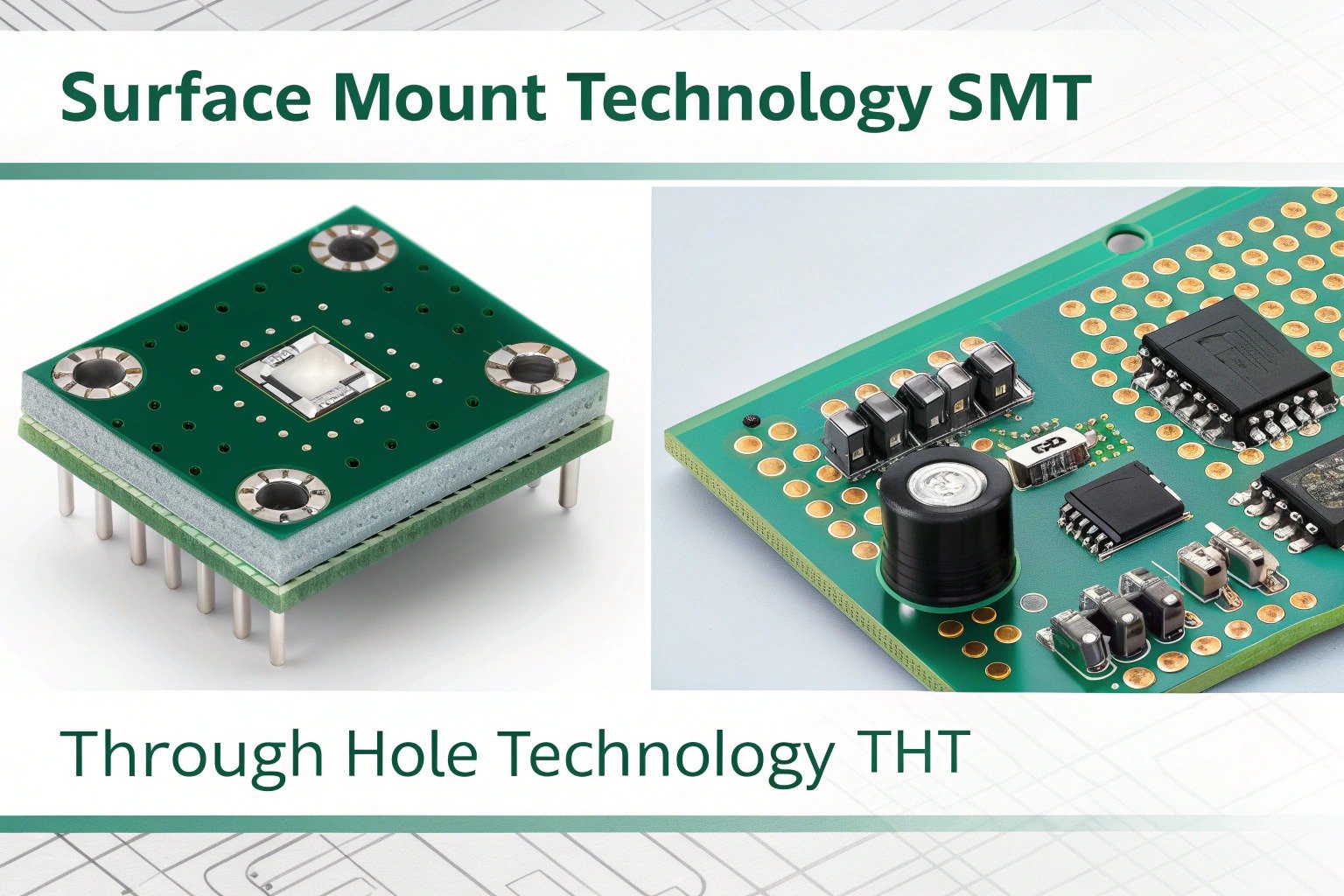

SMT (Surface Mount Technology) and Through-Hole are two PCB assembly methods. SMT places components directly onto the board’s surface, while Through-Hole inserts leads into holes. Each has unique strengths.

In electronics manufacturing, the way components are mounted on a circuit board directly impacts cost, reliability, and scalability. Most PCBs today use Surface Mount Technology (SMT), but Through-Hole Technology (THT) still plays an important role, especially in high-stress environments.

Understanding the difference between these two methods will help you design better boards, avoid unnecessary costs, and choose the right process for your application—whether it’s a small prototype or full-scale industrial product.

✔

While SMT components are typically compact, power components, connectors, and even microprocessors are often available in surface-mount packages.

✖

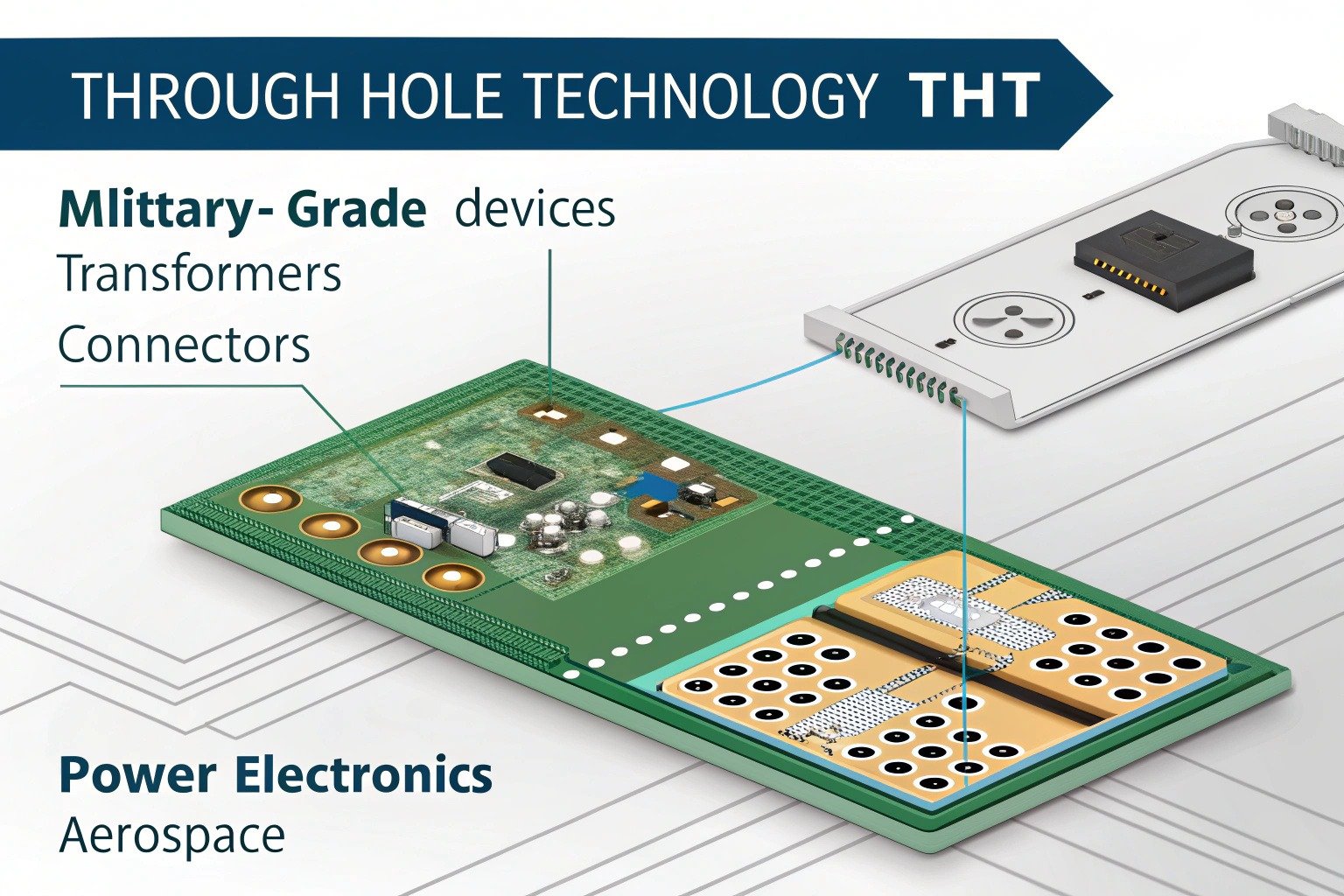

Because components are soldered through the board, Through-Hole offers greater mechanical strength and is preferred for stress-prone applications.

What Is SMT Assembly?

SMT, or Surface Mount Technology, is the most common method used in modern PCB assembly. In this process, components—called SMDs (Surface Mount Devices)—are placed directly onto the surface of the circuit board using solder paste and a reflow oven. There’s no need for drilling holes, which reduces both time and material cost.

SMT components are typically smaller and lighter than through-hole parts. That’s why SMT is ideal for high-speed, high-density designs like smartphones, laptops, and smartwatches.

Automation is a big advantage here. SMT supports fast pick-and-place machines and inline inspection systems, making it suitable for mass production with low defect rates. Even complex boards with thousands of parts can be assembled quickly using this technique.

To see SMT machines in action, check out this factory tour from JLCPCB.

What Is Through-Hole Assembly?

Through-Hole Technology involves inserting component leads into drilled holes on the PCB and soldering them on the opposite side—either manually or using wave soldering. This method offers a stronger mechanical bond, making it ideal for components that experience stress, like connectors, transformers, or large capacitors.

THT is still used in:

- Aerospace and military equipment

- Automotive ECUs and power modules

- Prototyping or lab-based debugging

- DIY and educational electronics kits

The downside is slower assembly, larger component size, and limited layout flexibility. Through-hole parts take up more board space and typically require manual handling, which increases labor costs.

Despite these challenges, through-hole remains valuable for specific use cases where reliability and repairability matter more than speed or size.

Key Differences Between SMT and Through-Hole

Here’s a side-by-side comparison to understand the distinctions clearly:

| Feature | SMT Assembly | Through-Hole Assembly |

|---|---|---|

| Mounting Method | Soldered on surface | Inserted into drilled holes |

| Component Size | Small and compact | Larger with leads |

| Board Density | High | Low to moderate |

| Mechanical Strength | Lower | Higher (better for stress zones) |

| Assembly Speed | Fully automated | Slower, often manual |

| Cost Efficiency | More economical for high volumes | Higher cost per unit |

| Best For | Consumer electronics, wearables, IoT | Power electronics, aerospace, RF |

Which Should You Use?

There’s no one-size-fits-all answer. The choice depends on your application, volume, cost constraints, and environmental factors.

If you’re designing a compact device where space is at a premium, SMT is the obvious choice. It supports double-sided assembly, rapid automation, and high-density routing. On the other hand, if you’re building something that will be exposed to vibration, temperature swings, or manual rework, Through-Hole may offer the durability you need.

In fact, many modern PCBs use a hybrid approach: SMT for small components and through-hole for connectors or high-load elements. This allows you to benefit from both speed and stability.

When discussing with your contract manufacturer, be sure to provide clear documentation on which parts are THT vs. SMT. Most professional EMS providers, such as MacroFab or Tempo Automation, will help optimize your assembly plan to balance cost, speed, and reliability.

Conclusion

Understanding the difference between SMT and Through-Hole assembly is essential for anyone involved in PCB design or manufacturing. While SMT offers speed and size advantages, Through-Hole provides unmatched durability in tough environments.

Your decision should be based on the application—not just the technology. By choosing wisely, you can build products that are not only efficient to manufacture, but also built to last.